Top Rubber Refiner Mixing Mill Service Providers in Gujarat

Top Rubber Refiner Mixing Mill Service Providers in Gujarat

Gujarat has become a leading hub for industrial rubber processing in India. Due to Gujarat’s strategic location, industrial infrastructure, and supportive government policies, many entrepreneurs are investing in rubber refiner mixing mill. These machines play a critical role in reclaiming and processing rubber waste, which helps reduce environmental damage and improve cost-efficiency.

In this article, we’ll cover the practical advantages of setting up a rubber refiner machine unit, explore government support for rubber machinery services in Gujarat, highlight key industrial zones ideal for setting up a plant, and explain why Vatsntecnic is a trusted provider of new and used rubber refiner mixing mills.

Why Start a Rubber Refining Mill in Gujarat? Key Benefits Explained

Setting up a rubber refining unit brings many direct and long-term advantages. These machines are used to process reclaimed rubber, reduce material waste, and improve quality control.

- Low Cost of Operations

- The rubber refining plants employ recycled rubber, which is less expensive compared to virgin material. This lowers the cost of manufacture.

- Strong Demand for Reclaimed Rubber

- The manufacturing industries of automotive, footwear, and infrastructure require high levels of reclaimed rubber. This provides constant business growth.

- Quick ROI

- With the right location and equipment, most units recover their investment within 2–3 years.

- Scalable Operations

- These mills allow flexible scaling. Start small and grow based on demand and supply.

- Contribution to Sustainability

- Using scrap rubber helps reduce landfills and promotes circular manufacturing. It aligns with modern green business practices.

Government Assistance for Rubber Refiner Machinery Services in Gujarat

The Gujarat government has a number of plants with numerous subsidy schemes and financial incentives to encourage manufacturing units. These schemes are developed to promote industrial growth, especially in rubber and plastic industries.

- Capital Investment Subsidies

- In the Gujarat Industrial Policy, enterprises can avail themselves of up to a 25% subsidy on new equipment, such as rubber mixing mills.

- Interest Subsidy on Loans

- Small and medium businesses may qualify for interest subsidies on term loans taken for setting up plants.

- Power Tariff Concessions

- Units located in industrial zones often receive discounted electricity rates for the first five years of operation.

- Stamp Duty Refunds

- Startups setting up rubber refining facilities in designated industrial areas can claim up to 100% stamp duty refund.

These schemes lower the entry barrier for entrepreneurs and make rubber refiner mill services in Gujarat a viable option.

Best Industrial Areas to Establish a Rubber Refiner Mixing Mill in Gujarat

Location selection is a deciding factor in the success of a business. Gujarat has a plethora of developed industrial areas that are suitable for the installation of rubber machinery and service.

- GIDC Vapi

- Situated in South Gujarat, Vapi specializes in chemical and rubber industries. It has developed roads and ports in close proximity.

- GIDC Vatva, Ahmedabad

- Vatva consists of several medium- and large-sized manufacturing plants. It is blessed with ideal logistics and a supply of raw material.

- GIDC Dahej

- Dahej is a significant industrial park with direct sea connectivity. It’s best suited for companies engaged in the export of reclaimed rubber.

- Sanand Industrial Estate

- Near Ahmedabad, Sanand provides decent infrastructure, qualified labor, and proximity to OEMs in the auto industry.

- GIDC Halol

- Halol has budding manufacturing activity with improved infrastructure and connectivity to local markets.

These areas are provided with power, roads, water, and access to suppliers and buyers—thus making them perfect places to establish your rubber refiner machinery factory.

Why Choose Vatsntecnic for Buying or Selling Rubber Refining Machinery?

When it comes to buying or selling rubber refining machines in Gujarat, Vatsntecnic stands out. Here’s why many businesses trust us.

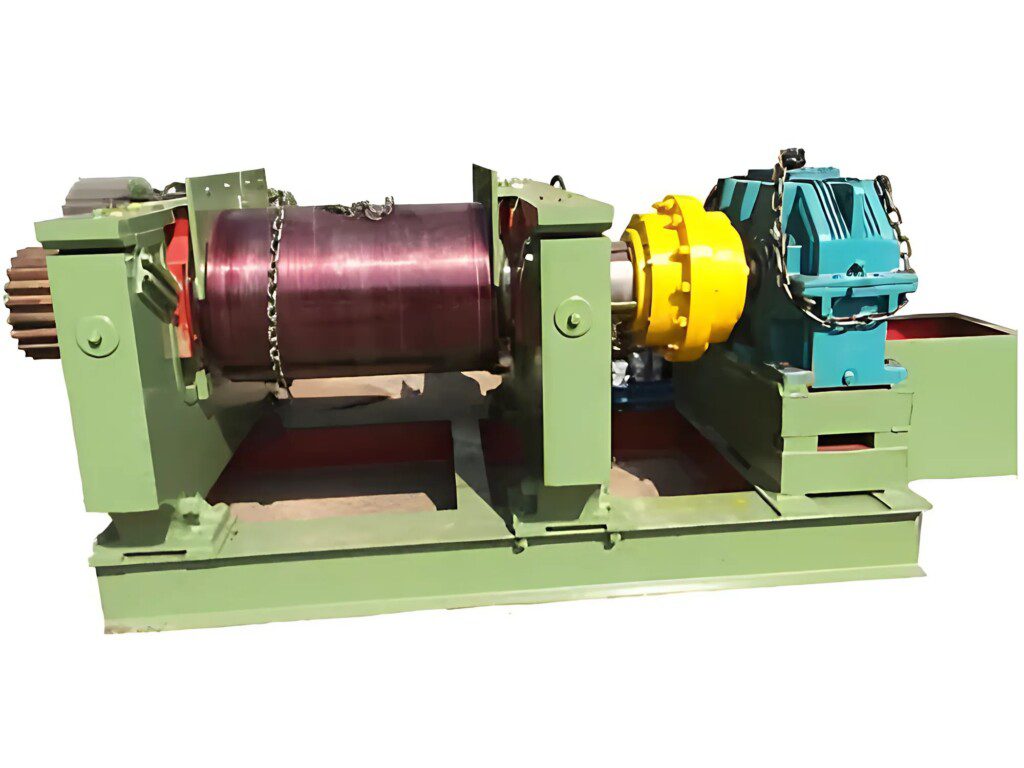

- Wide Range of Equipment

- Vatsntecnic offers both new and used rubber refiner mixing mills at competitive prices. All machines are tested for performance and durability.

- Customized Solutions

- Need a machine for specific output? Vatsntecnic provides tailored machinery solutions as per customer requirements.

- Affordable Pricing

- We enable you to gain value for money. Whether looking for new or used machinery, we provide good quality at an affordable cost.

- Quick Delivery & Support

- Our logistics team ensures timely delivery across Gujarat. We also offer installation support and after-sales service.

- Industry Expertise

- With years of experience in the rubber machinery sector, we know what works best for your setup.

Partnering with Vatsntecnic ensures you make the right investment in rubber refiner machinery.

Conclusion

Gujarat is fast becoming a hub for rubber machinery services. From strong industrial infrastructure to government incentives, the state offers everything needed to start and grow a rubber refiner machine business.

If you are searching for reputable equipment suppliers, Vatsntecnic is your best partner. We can help you get setup with reliable, efficient and economical rubber refiner mixing mills – new and used.

Frequently Asked Questions (FAQs)

1. How much space is needed for installation of a rubber refiner mixing mill?

- A small unit will require a minimum of 2,000 sq. ft. If bigger installations, you could take over 5,000 sq. ft.

2. Can rubber that comes from refiner mills be recycled as raw material for tire manufacturing?

- Yes, reclaimed rubber is usually used in tires—legitimately, I mean, realistically; specifically the sidewalls, treads, tubes.

3. How long will a used rubber refiner machine last?

- A properly maintained second-hand machine should work well for 5–10 years or longer.

4. Can I upgrade a second-hand rubber mixing mill with new parts?

- Yes, you can upgrade many parts, including rollers, gearboxes, and control panels.

For more information, Visit Here

Compression Molding

Compression Molding