Used Tire Building Machine and Making Process

Exploring the Used Secondary Tire Building Machine and Making Process-

Tire Building Machine manufacturing is an intricate process that involves multiple stages, precise machinery, and expertise. Understanding the tire-making process, the machinery involved, and the types of machines used is crucial in comprehending this industry.

1. Tire-Making Process Explained

The tire manufacturing process is a blend of engineering, chemistry, and precision. It encompasses various stages:

i)Compounding: Raw materials like natural rubber, synthetic rubber, carbon black, and other chemicals are mixed in precise quantities to form the rubber compound.

ii)Tire Building: Involves the assembly of various components like tread, sidewall, inner liner, and beads using a tire building machine.

iii)Curing: The green tire is subjected to high heat and pressure in a curing press to vulcanize and shape it.

iv)Finishing: In this stage, the tire undergoes inspection, trimming, and testing before being ready for sale.

2. Machinery Required for Tire Manufacturing

Several machinery types contribute to the tire manufacturing process:

i)Mixing Equipment: Internal mixers, mills, and extruders are used for compounding and mixing raw materials.

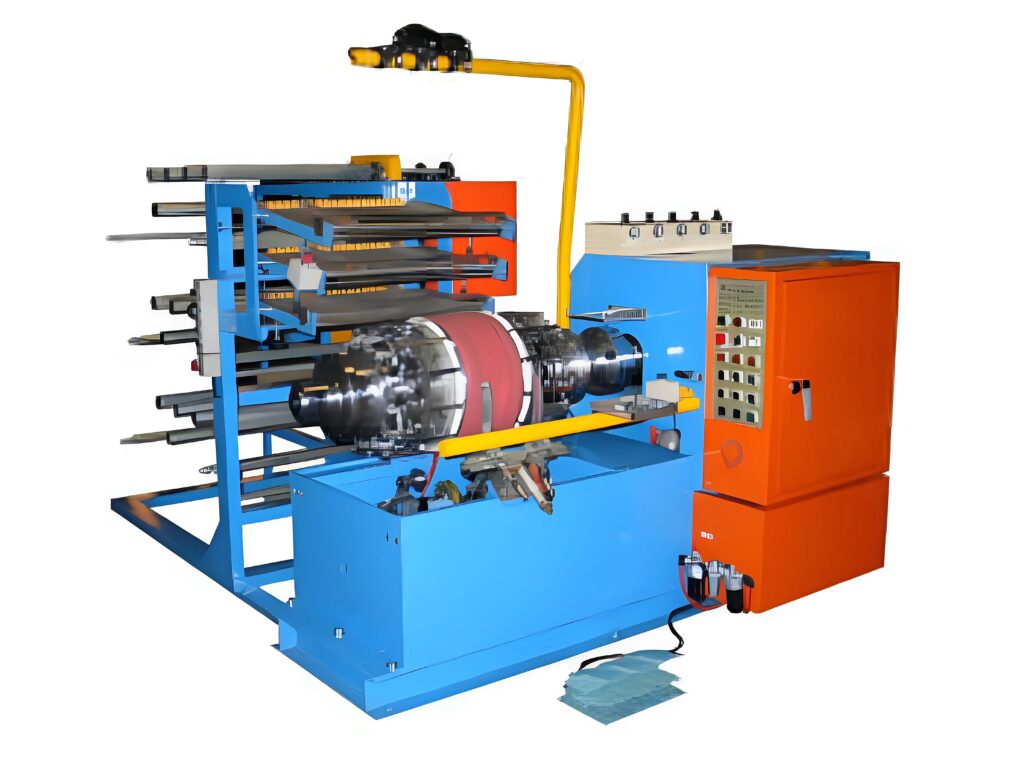

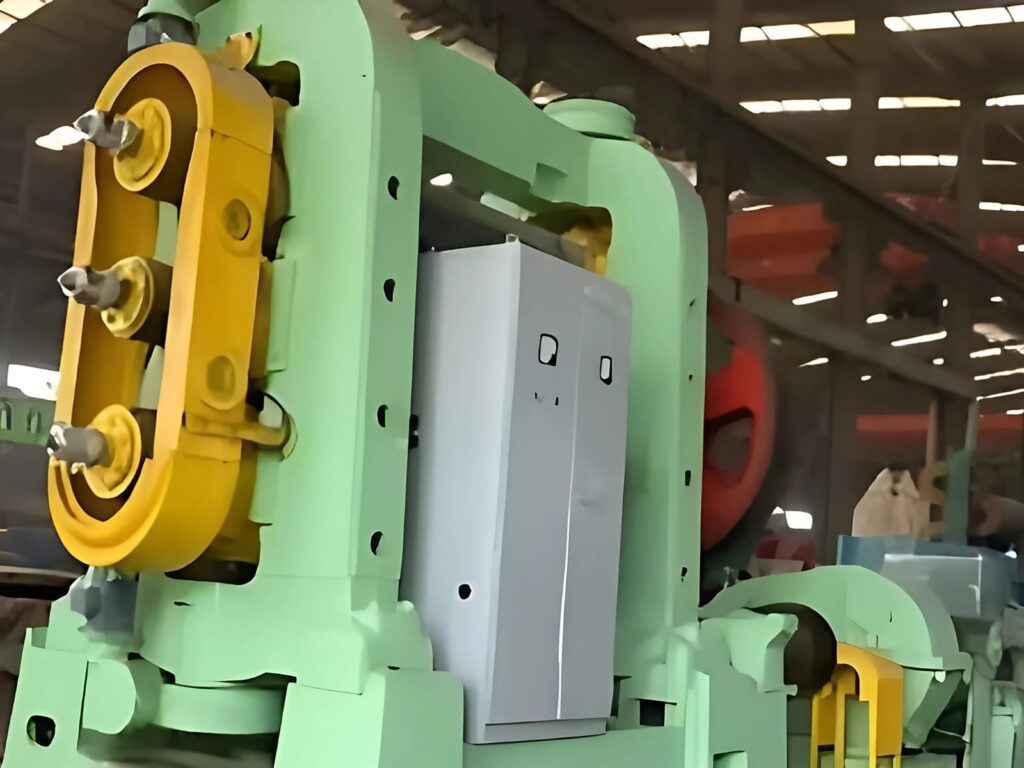

ii)Tire Building Machines: Include secondhand tire-building machines that assemble various tire components into the final shape.

iii)Curing Presses: Vital for vulcanization and shaping of the green tire.

iv)Testing Equipment: Used for quality checks and inspection of finished tires.

Exploring Machine Types and Usage-

Different types of tire-building machines cater to specific tire manufacturing needs. They use radial tire-building machines, bias tire-building machines, and drum-type building machines. Each serves its purpose in creating different types of tires, such as passenger, truck, or specialty tires.

At Vatsn Tecnic, we specialize in buying and selling surplus machinery from renowned tire brands in India, including but not limited to MRF, Apollo Tyres, CEAT, JK Tyre, and Birla Tyres. With our extensive network and experience since 1984, we offer quality machinery for rubber processing at competitive prices.

Types of Tires-

Tires vary based on their application and construction. Some common types include:

i)Passenger Tires: Designed for cars and offers a balance of comfort, handling, and durability.

ii)Truck Tires: Sturdy tires built for heavy-duty use in trucks, providing stability and load-bearing capacity.

iii)Off-road Tires: Specifically crafted for off-road vehicles, offering traction and durability on rough terrain.

conclusion-

Vatsn Tecnic stands as a reliable hub for used machinery in the rubber processing industry. With Vikram S Bansala’s vision and guidance since 1984, our commitment to providing quality used machinery remains unwavering.

For any inquiries regarding used machinery, Vatsn Tecnic is your trusted partner, catering to your rubber processing needs.

Compression Molding

Compression Molding