Types of Drums In Tire Building Machines

In the realm of tire manufacturing, efficiency, precision, and cost-effectiveness are paramount. This is where tire-building machines play a pivotal role. At Vatsn Tecnic, we pride ourselves on being at the forefront of providing cutting-edge solutions for tire production. With our extensive expertise and commitment to excellence, we offer a range of tire-building machines tailored to meet the diverse needs of our clients.

1. Understanding Tire Building Machines –

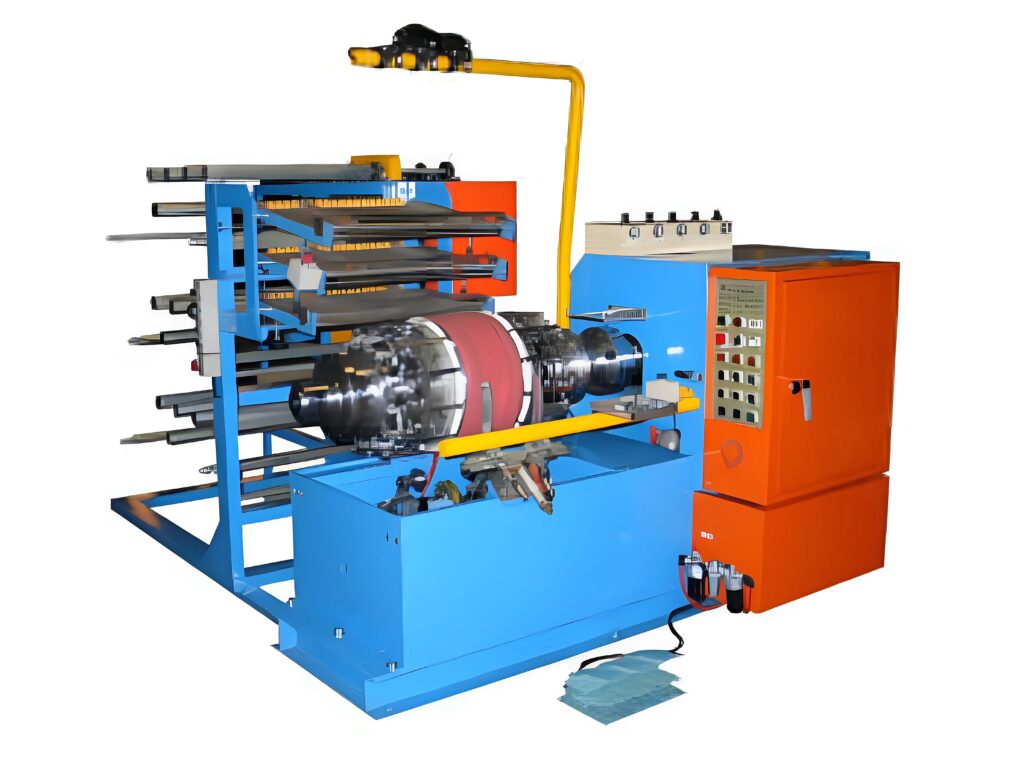

Tire-building machines are sophisticated pieces of equipment designed to automate the tire assembly process. They consist of multiple stations where various components of the tire, such as the carcass, inner liner, sidewalls, and tread, are assembled in precise layers. These machines ensure uniformity, consistency, and efficiency in tire production, ultimately leading to higher-quality end products.

2. Types of Drums in Tire Building Machines –

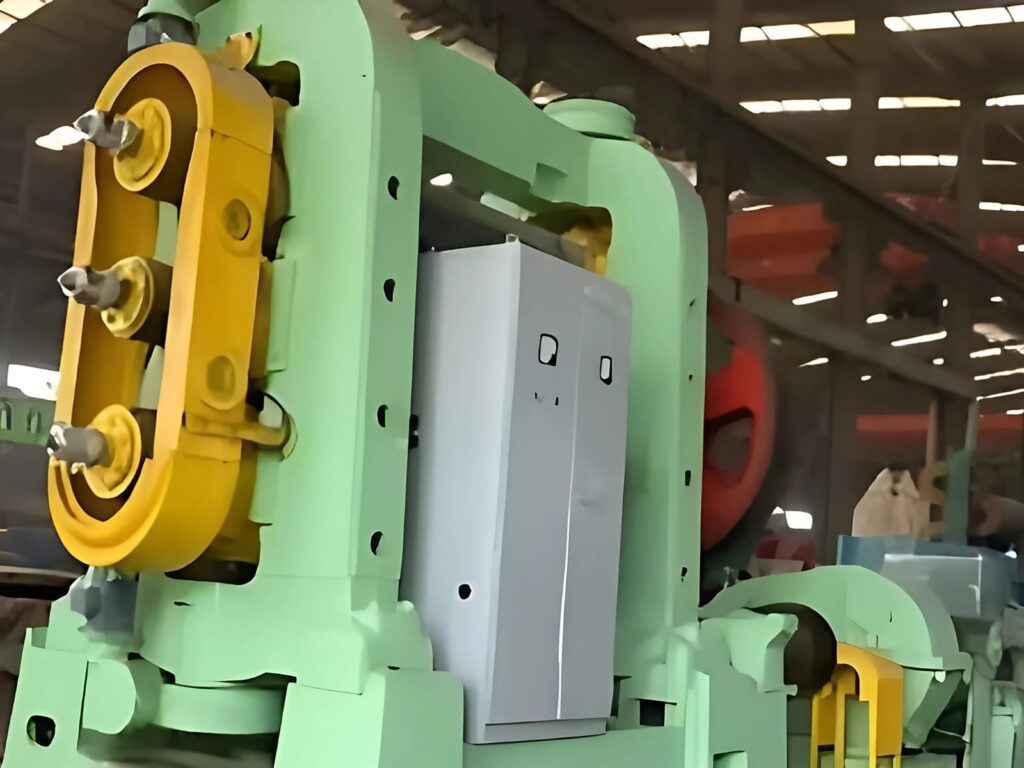

There are primarily two types of drums used in tire-building machines: manual drums and automatic drums. Manual drums require operators to manually place and align tire components during the building process. While these drums may be more cost-effective initially, they can be labor-intensive and prone to human error. On the other hand, automatic drums feature advanced robotic systems that automate the tire-building process, offering greater precision, speed, and efficiency. Although automatic drums may have a higher upfront cost, they often provide significant long-term savings through increased productivity and reduced operational costs.

3. Cost Comparison: Manual vs Automatic Drums –

In terms of cost, it’s essential to consider both the initial investment and the long-term operational expenses. While manual drums may have a lower initial cost, they typically require more labor and may incur higher maintenance costs due to the potential for human error. On the other hand, automatic drums may have a higher upfront cost, but they offer higher productivity, lower labor costs, and reduced downtime, resulting in long-term savings and improved profitability.

4. Benefits of Used Machinery –

Investing in used machinery can offer several benefits for tire manufacturers. Firstly, it allows for significant cost savings compared to purchasing new equipment. Additionally, used machinery from reputable suppliers like Vatsn Tecnic undergoes thorough inspection and refurbishment processes to ensure optimal performance and reliability. Furthermore, buying used machinery can often lead to faster implementation and reduced lead times, enabling manufacturers to ramp up production more quickly and stay competitive in the market.

5. How to Buy from Vatsn Tecnic –

At Vatsn Tecnic, we understand the importance of providing our clients with high-quality, reliable machinery that meets their specific requirements. Our team of experts works closely with customers to assess their needs and recommend the most suitable solutions. Whether you’re looking for new or used tire-building machines, we offer a comprehensive range of options. Our transparent pricing, extensive warranties, and dedicated customer support ensure a seamless purchasing experience from start to finish.

Conclusion –

Tire-building machines are indispensable for modern tire manufacturing, offering unmatched precision, efficiency, and cost-effectiveness. Tire manufacturers can streamline their production processes, improve product quality, and maximize profitability by investing in the right equipment, such as automatic drums. At Vatsn Tecnic, we are committed to empowering tire manufacturers with state-of-the-art solutions that drive success in today’s competitive market.

For more information Visit Here

Compression Molding

Compression Molding