Rubber Dispersion Kneader in Allahabad: A Complete Industrial Guide

Rubber Dispersion Kneader in Allahabad: A Complete Industrial Guide

The rubber industry is considered a rapidly growing sector in Allahabad. That is why most manufacturers nowadays prefer installing a Rubber Dispersion Kneader Machine for improved efficiency. This machine offers accuracy, higher output, and quality mixing stability. Furthermore, it provides support to multiple kinds of rubber compounds, helping small and large units grow smoothly.

New rubber units have found Allahabad to be a favorable destination because of the rising demand for their products. This guide discusses everything that you should know before setting up a Rubber Dispersion Kneader in Allahabad.

Advantages of a Rubber Dispersion Kneader Machine Installation

A kneader has many advantages for rubber processors. The most important of these are listed below.

- It produces uniform and consistent mixing.

- This reduces manual handling and increases safety.

- It helps in achieving accurate temperature control.

- It improves compound quality with fewer errors.

- It supports several rubber materials and their formulation.

- Labor costs are reduced and daily output increases.

- It decreases energy wastage by efficiently mixing.

- It enhances long-term production reliability.

- It handles both small and large batch sizes with ease.

- It helps the unit to maintain stable product quality.

Purpose of a Rubber Dispersion Kneader in Manufacturing Plants

The following is a brief explanation of how a kneader plays an important role in rubber processing.

- It mixes rubber with chemicals and fillers.

- It breaks down materials for better dispersion.

- It prepares homogenous rubber compounds.

- This will ensure uniform additive distribution.

- It simplifies pre-mixing before milling or extrusion.

Thus, the machine becomes a core machine in tyre, footwear, gasket, sealing, hose, conveyor belt, and molded product units.

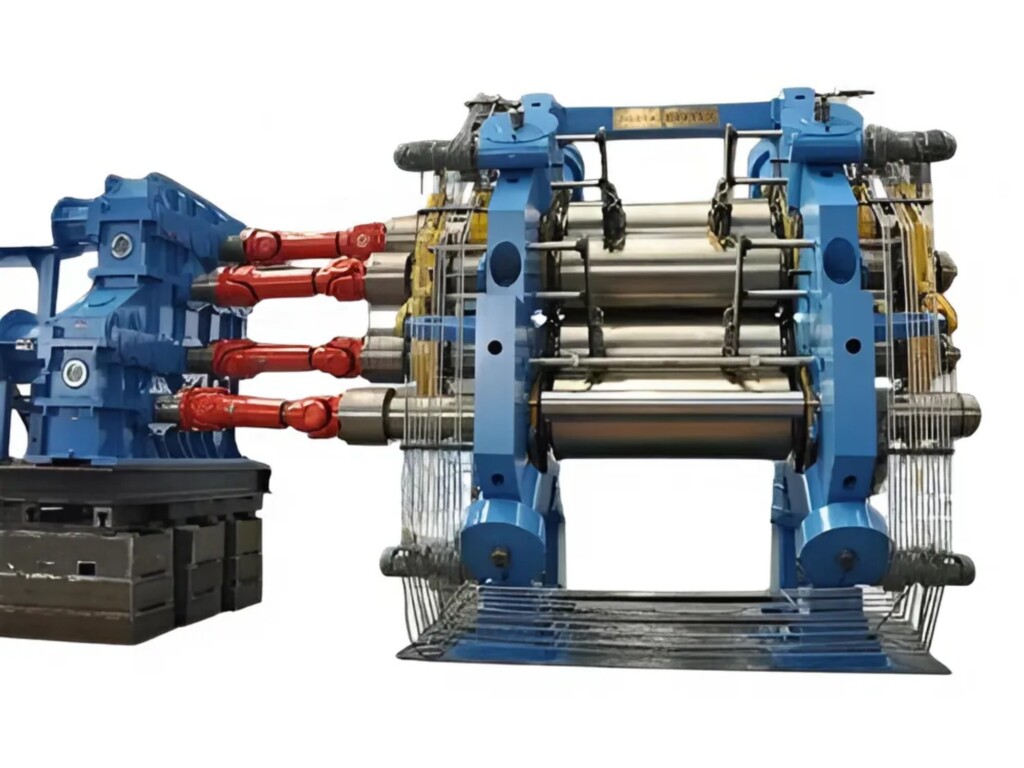

Types of Rubber Dispersion Kneaders Commonly Used in India

Manufacturing companies use various kneaders depending on the need for production. The major types are:

- Intermix Type Kneader – Characterized by strong mixing power and high stability.

- Tilting Type Kneader: Best for faster discharge and reduced downtime.

- Banbury Type Internal Mixer – Heavy-duty, industrial application purposes.

Each type supports unique production demands, and therefore, plant owners must choose based on batch size, material type, and budget.

Government Support for Setting Up Rubber Dispersion Kneader in Allahabad

Many entrepreneurs enquire about the schemes that support rubber units. As the rubber kneaders come into the category of general industrial machinery, the government extends certain indirect benefits. Given below are the options that may help the new investors:

- Benefits of MSME Registration: avails electricity concessions and loan subsidies.

- CLCSS: Credit Linked Capital Subsidy Scheme provides a subsidy towards machinery upgradation.

- PMEGP Scheme: To assist new entrepreneurs in setting up small manufacturing units.

- State Government Industrial Policies : Uttar Pradesh offers tax rebates and capital subsidies for new plants.

- Mudra Loan for Small Units: Supports small rubber workshops with easy financing. Although there is no specific scheme only for kneaders, these policies still lower the set-up costs.

Best Industrial Areas to Install a Kneader Machine in Allahabad

The right location boosts production and logistics. Allahabad has a number of industrial pockets suitable for rubber processing.

- Naini Industrial Area – suitable for medium and large-sized rubber plants.

- Bamrauli Industrial Zone – Suitable for new manufacturing units with easy land options.

- Shankargarh Industrial Belt: Best for units that require a large space.

- Jhunsi Industrial Cluster: It offers good connectivity and labour availability.

- Dhoomanganj Area: Suitable for semi-urban industrial set-ups.

- Allahabad-Phulpur Belt: Good for plants with heavy raw material inflow.

These districts offer smoother transport access and a strong industrial ecosystem.

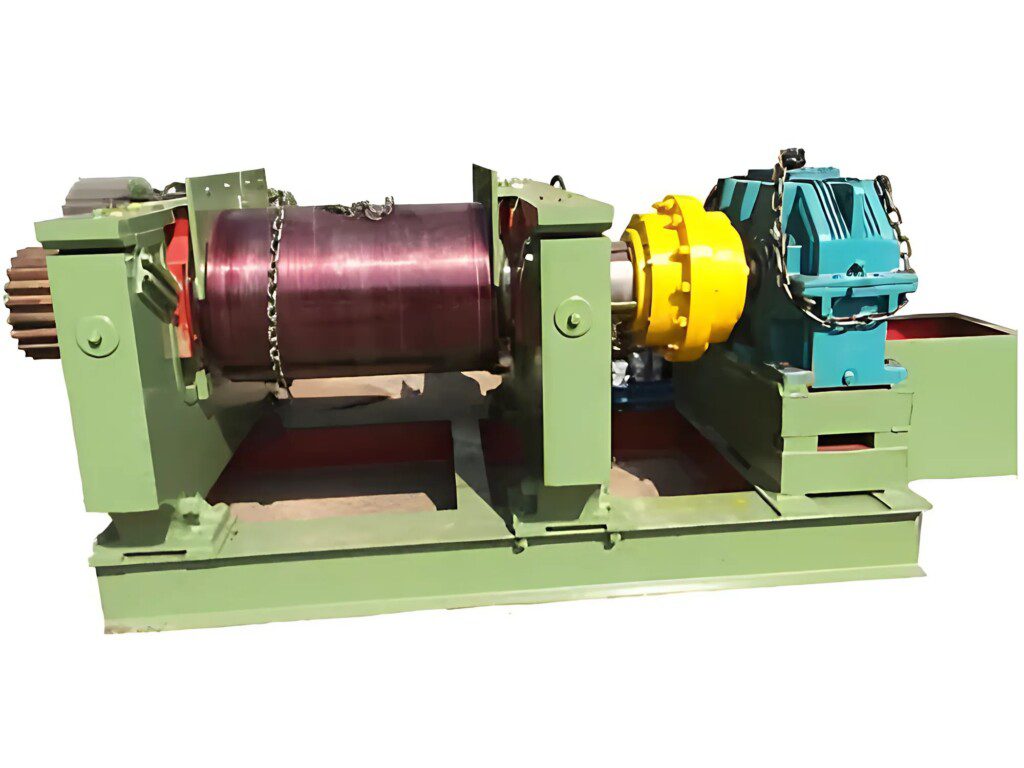

Why VatsnTecnic Is the Ideal Partner for Kneader Machines

The following reasons make VatsnTecnic stand as a trusted brand in the rubber machinery market, and buyers and sellers will prefer it.

- It offers new and secondhand kneader machines.

- It offers full refurbishment and test support.

- It helps buyers choose the right size of machinery.

- It supplies machinery across India, including Allahabad.

- It supports installation and operator training.

- It provides consultancy on plant layout and production flow.

- It purchases second-hand kneaders at reasonable prices.

- It ensures transparency in every deal.

- It maintains strong after-sales support.

- It has served industries for many years with consistent quality.

Thus, VatsnTecnic becomes a reliable partner for Rubber Dispersion Kneader for Sale.

Conclusion

A Rubber Dispersion Kneader in Allahabad assures enormous business potential. The machine improves the quality of mixing, reduces errors, and increases production speed. Allahabad also has various suitable industrial locations, with appropriate state-level support. Entrepreneurs are also eligible for advantages under the schemes of MSME and national subsidies.

As the kneader is often a significant investment, choosing the right supplier is of utmost importance. Therefore, VatsnTecnic stands out as a trusted source for new and used kneader machines, refurbishment, consultancy, and long-term service support.

Frequently Asked Questions

1. What is the production capacity of a Rubber Dispersion Kneader?

It depends on the model. Common sizes range from 25 to 150 liters and suit all types of rubber units.

2. Can a kneader mix various rubber compounds? Yes, it handles natural rubber, synthetic rubber, silicone, EPDM, EVA, and many mixes.

3. How much space is required to install a kneader? The space needed by a small kneader is limited, whereas a large 75-150 liter unit requires more floor area.

4. Does VatsnTecnic provide door delivery to Allahabad? Yes, VatsnTecnic provides nationwide supply and doorstep delivery for kneader machines.

For More Information, Visit Here

Compression Molding

Compression Molding