Retailer Rubber Molding in Nagaland

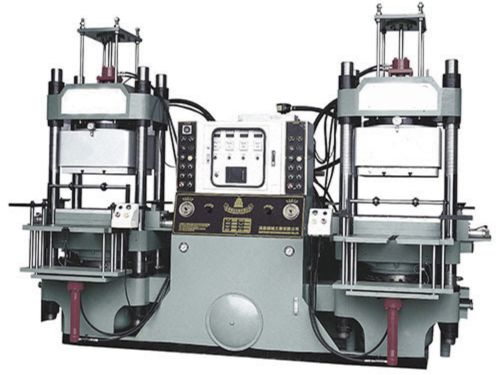

Retailer Rubber Compression Molding in Nagaland with a Strong Production Process and Industrial System Production Line

Retailer rubber compression molding in Nagaland supports regional manufacturing growth with precision and consistency.

Moreover, this niche relies on a stable production process and efficient industrial system production line.

Therefore, local firms focus on industrial manufacturing steps that reduce waste and improve throughput.

In addition, strong production system development helps suppliers meet global quality standards.

As a result, equipment production units in Nagaland now serve automotive, healthcare, and infrastructure clients.

Moreover, the machine making process delivers durable molds with tight tolerances.

Therefore, manufacturers optimize the industrial system production line for faster order fulfillment.

In addition, these efforts strengthen retailer rubber compression molding in Nagaland across supply chains.

As a result, buyers gain reliable products with predictable lead times.

Retailer rubber compression molding in Nagaland also benefits from skilled technicians and modern equipment production units.

Moreover, firms integrate advanced sensors into the production process for higher accuracy.

Therefore, industrial manufacturing steps now include digital inspection and automated trimming.

In addition, production system development supports scalable growth for new contracts.

As a result, the machine making process maintains quality during volume increases.

Moreover, the industrial system production line reduces downtime through predictive maintenance.

Therefore, customers trust retailer rubber compression molding in Nagaland for long term partnerships.

Benefits of a Reliable Production Process in Maharashtra within the Industrial System Production Line

-

Moreover, steady industrial manufacturing steps improve yield across equipment production units.

-

Therefore, strong production system development reduces scrap during the machine making process.

-

In addition, a stable production process lowers operational risks on the industrial system production line.

-

As a result, firms achieve consistent delivery for retailer rubber compression molding in Nagaland.

-

Moreover, optimized industrial manufacturing steps boost energy efficiency across equipment production units.

-

Therefore, the machine making process ensures repeatable quality through production system development.

Government Scheme for Setting Up a Trusted Supplier using the Production Process and Industrial Manufacturing Steps

-

Moreover, MSME schemes support equipment production units with affordable financing.

-

Therefore, industrial development grants improve the machine making process.

-

In addition, technology upgrades strengthen production system development.

-

As a result, subsidies enhance the industrial system production line.

-

Moreover, export incentives expand the production process for global markets.

Major Industrial Areas for Setting Up using the Production Process and Industrial System Production Line

-

Moreover, Dimapur Industrial Estate supports equipment production units and industrial manufacturing steps.

-

Therefore, Kohima Growth Center enables a modern machine making process.

-

In addition, Mokokchung Hub promotes production system development.

-

As a result, Tuensang Park expands the industrial system production line.

-

Moreover, Phek Zone strengthens the regional production process.

How Industrial Systems Are Made | Step-by-Step Manufacturing Process with Production Process and Industrial Manufacturing Steps

First, teams plan the production process with clear targets.

Moreover, engineers map industrial manufacturing steps for efficiency.

Therefore, designers finalize production system development with digital models.

In addition, procurement secures raw materials for equipment production units.

Next, machinists start the machine making process with precision tools.

Moreover, they align molds along the industrial system production line.

Therefore, technicians calibrate machines to stabilize the production process.

In addition, sensors verify industrial manufacturing steps in real time.

Then, operators load compounds for retailer rubber compression molding in Nagaland.

Moreover, presses apply controlled heat during the machine making process.

Therefore, molds shape parts within the industrial system production line.

In addition, cooling stations protect the production process.

Afterward, inspectors check components through industrial manufacturing steps.

Moreover, data supports ongoing production system development.

Therefore, equipment production units release approved batches.

In addition, packaging moves through the industrial system production line.

Finally, logistics teams dispatch orders from the production process.

Moreover, tracking tools enhance industrial manufacturing steps.

Therefore, clients receive consistent quality from the machine making process.

As a result, retailer rubber compression molding in Nagaland meets strict specifications.

Why Choose VatsnTecnic? for Industrial Machine Manufacturing with Production Process and Industrial System Production Line

VatsnTecnic delivers proven benefits through a disciplined production process.

Moreover, the firm designs industrial manufacturing steps for high reliability.

Therefore, clients gain advanced production system development support.

In addition, equipment production units receive robust training.

As a result, the machine making process achieves predictable outcomes.

VatsnTecnic also provides responsive technical support.

Moreover, experts monitor the industrial system production line continuously.

Therefore, they resolve issues before they affect the production process.

In addition, analytics improve industrial manufacturing steps.

As a result, uptime increases across equipment production units.

VatsnTecnic maintains strong reliability.

Moreover, audits protect the machine making process.

Therefore, compliance supports production system development.

In addition, certifications strengthen the industrial system production line.

As a result, partners trust every production process.

Delhi Government Schemes supporting Production Process and Industrial Manufacturing Steps

-

Moreover, capital subsidies strengthen equipment production units.

-

Therefore, skill programs enhance the machine making process.

-

In addition, innovation grants improve production system development.

-

As a result, tax benefits support the industrial system production line.

-

Moreover, export assistance expands the production process.

Retailer rubber compression molding in Nagaland continues to attract new investments.

Moreover, the region supports modern industrial manufacturing steps.

Therefore, firms scale production system development with confidence.

In addition, equipment production units upgrade the machine making process.

As a result, the industrial system production line delivers competitive advantages.

Retailer rubber compression molding in Nagaland also supports local employment.

Moreover, training improves the production process.

Therefore, young technicians master industrial manufacturing steps.

In addition, mentors guide production system development.

As a result, equipment production units gain skilled operators.

Retailer rubber compression molding in Nagaland strengthens regional exports.

Moreover, quality control improves the machine making process.

Therefore, the industrial system production line meets international norms.

In addition, logistics align with the production process.

As a result, customers receive reliable shipments.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

Compression Molding

Compression Molding