Difference Between Rubber Cracker Mill and Rubber Griner Mill

Rubber Cracker Mill and Rubber Griner Mill are two crucial machines used in the rubber industry, each serving distinct purposes in the processing and recycling of rubber materials. These machines, manufactured by Vatsn Tecnic, differ significantly in their functions, operations, and applications and play vital roles in rubber cracking and grinding.

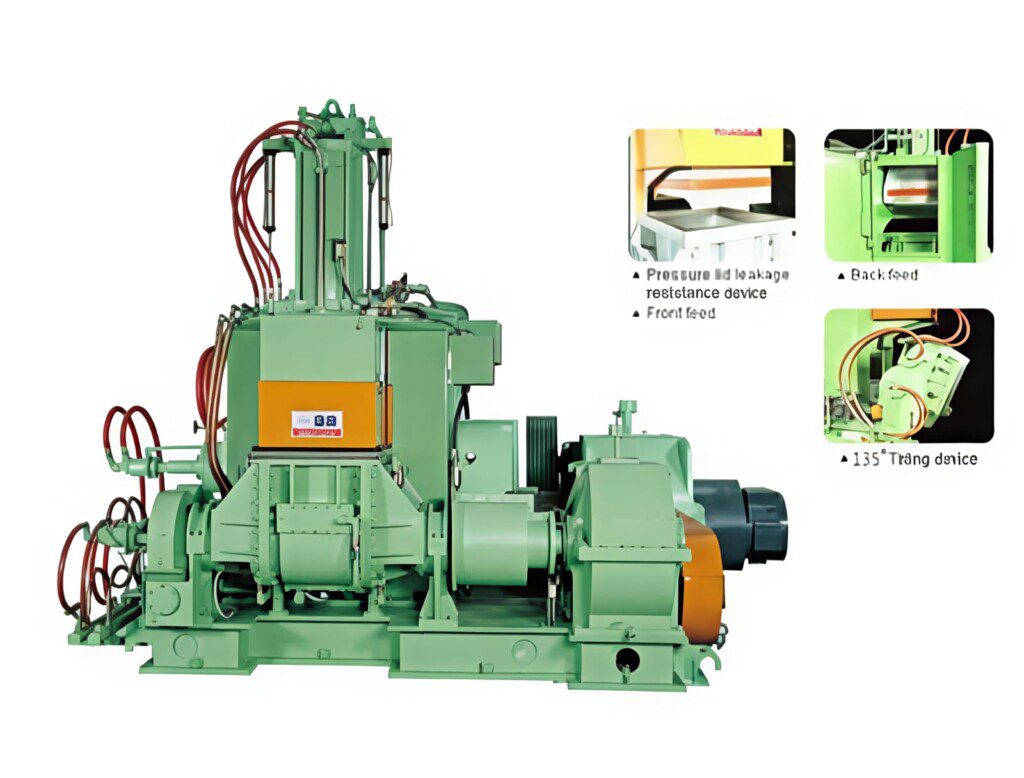

Rubber Cracker Mill-

1.)Functionality:

A Rubber Cracker Mill is primarily designed to break down rubber materials into smaller pieces, often called “crumb rubber.” It applies high shear and compression forces to rubber compounds, breaking them into smaller particles or sheets.

2.)Operating Principle:

Rubber Cracker Mills usually consists of two counter-rotating rolls with serrated surfaces. The rubber material is fed between these rolls, undergoing a controlled process of crushing and shearing, resulting in reduced particle sizes.

3.)Application:

The crumb rubber produced by the Rubber Cracker Mill serves as an intermediate product. It is further processed in other machines, like the Rubber Grinder Mill, to attain finer particle sizes suitable for various applications.

4.)Uses:

- I am breaking down rubber compounds into smaller particles or sheets.

- I am preparing rubber material for subsequent processing stages.

- Producing crumb rubber used as a raw material in various industries.

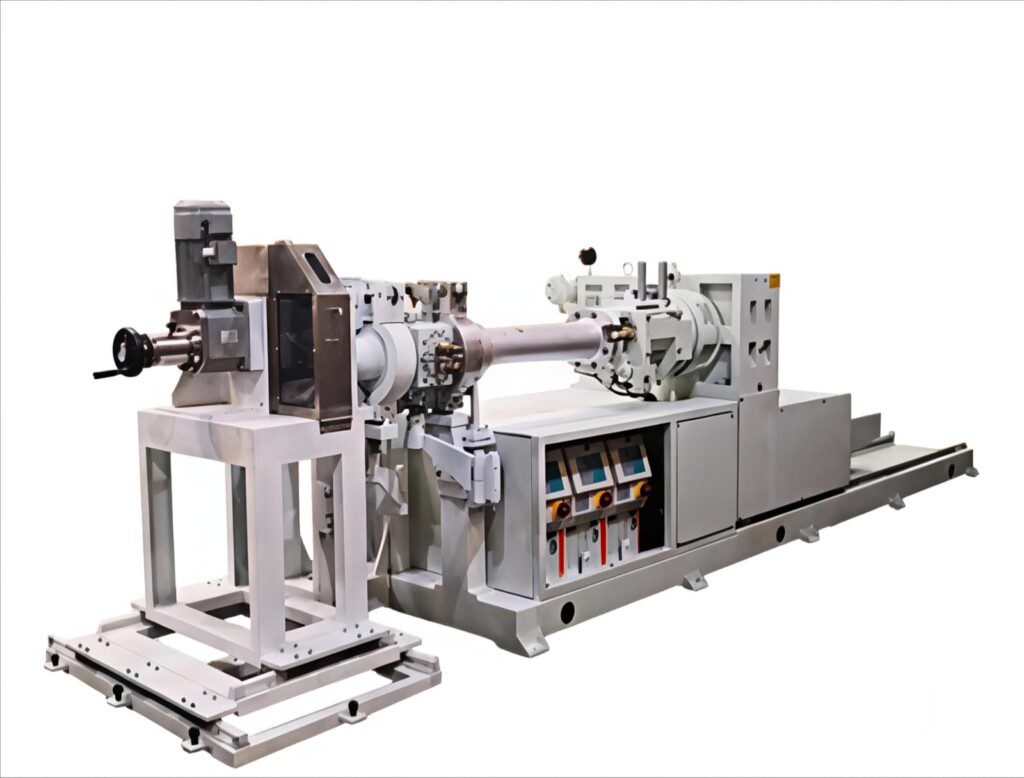

Rubber Grinder Mill-

1.)Functionality:

A Rubber Grinder Mill, also known as a Rubber Powder Grinder, focuses on refining the crumb rubber obtained from the Cracker Mill into fine rubber powder of desired particle sizes.

2.)Operating Principle:

This machine utilizes high-speed rotating blades or discs within a grinding chamber to reduce the crumb rubber further into fine powder. The grinding process ensures uniform particle size distribution, enhancing its usability in various applications.

3.)Application:

The Rubber Grinder Mill produces finely ground rubber powder, suitable for direct utilization in several industries without further processing.

4.)Uses:

- Producing fine rubber powder from crumb rubber for various applications in industries like rubber manufacturing, construction, sports surfaces, and molded products.

- Recycling waste rubber materials into a valuable resource for multiple industries.

Differences Between Rubber Cracker Mill and Rubber Grinder Mill-

i)Purpose: The Rubber Cracker Mill focuses on breaking down rubber into crumb rubber, while the Rubber Grinder Mill refines this crumb rubber into fine powder.

ii)Output: Cracker Mills produces crumb rubber as an intermediate product, whereas Grinder Mills produces finely ground rubber powder suitable for direct use.

iii)Function: Cracker Mills emphasize breaking and shearing rubber compounds, while Grinder Mills focus on grinding and refining rubber crumbs into fine particles.

iv)Application Stage: Cracker Mills serve as a preparatory stage, and the output is further processed in Grinder Mills to obtain the desired particle sizes for specific applications.

Conclusion-

The Rubber Cracker Mill and Rubber Grinder Mill, both made by Vatsn Tecnic in India, are crucial for recycling and processing rubber materials. The Cracker Mill breaks down rubber into crumb rubber, while the Grinder Mill refines it into a fine powder. These machines offer distinct functionalities in the material processing chain of the rubber industry.

Compression Molding

Compression Molding