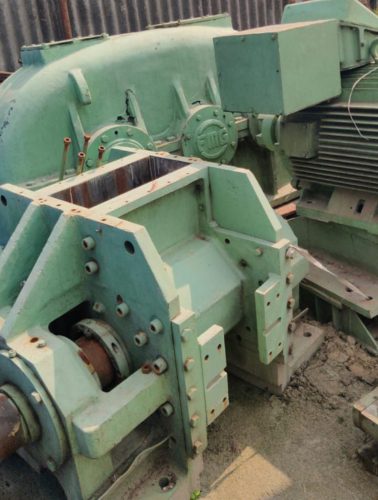

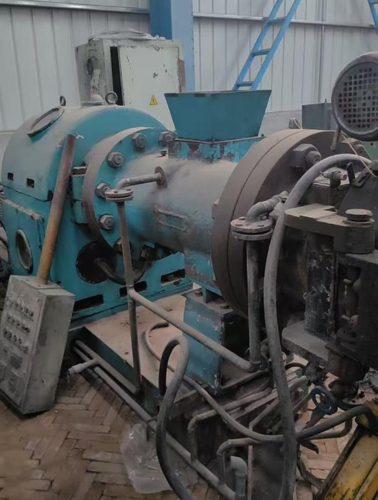

35L Rubber Banbury Mixer 125 HP for Sale

| Model | VAT-45E | VAT-90E | VAT-135E | VAT160E | VAT-190E | |

| Total volume of mixing chamber (L) | 45 | 90 | 135 | 160 | 190 | |

| Working volume of mixing chamber (L) | 30 | 56 | 90 | 104 | 125 | |

| Speed of rear rotor (r/min) | 6-60 | 5-50 | 6-60 | 5-50 | 6-60 | |

| Rotor speed ratio | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | |

| Compressed air pressure (mpa) | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | |

| Cooling water pressure (mpa) | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | |

| Main motor power (kw) | 280 | 450 | 720 | 750 | 1100 | |

Overall dimension (mm) | (L) | 6200 | 7400 | 8200 | 8600 | 9000 |

| (W) | 2500 | 2880 | 2950 | 3000 | 4000 | |

| (H) | 3750 | 4700 | 5375 | 6000 | 6220 | |

| Weight (T) | 15 | 23 | 29 | 39 | 45 | |

35L Rubber Banbury Mixer 125 HP for Sale – Industrial Mixing Solution

A 35L Rubber Banbury Mixer 125 HP for Sale is a smart investment for rubber processors who want consistent compound quality, high productivity, and long-term operational stability. This internal mixer suits small to mid-scale rubber manufacturing units that focus on precision, repeatability, and energy efficiency. Industrial Banbury Mixer Sale eWith growing demand for rubber products across automotive, footwear, and industrial sectors, setting up a 35L rubber Banbury mixer helps businesses scale faster and stay competitive.

Benefits of Setting Up a 35L Rubber Banbury Mixer 125 HP

Choosing a 35L Rubber Banbury Mixer 125 HP for Sale brings multiple operational advantages. First, it delivers uniform dispersion of fillers, polymers, and chemicals, which directly improves product quality. Second, the 125 HP motor ensures strong torque, allowing faster mixing cycles without overheating the compound.

In addition, this mixer reduces raw material wastage due to controlled mixing parameters. As a result, manufacturers achieve better batch consistency. Moreover, the compact 35-liter chamber requires less floor space, making it ideal for factories with limited layouts. Over time, lower power consumption and reduced labor dependency increase overall profitability.

Government Scheme for Setting Up a 35L Rubber Banbury Mixer 125 HP

The Indian government actively supports manufacturing units installing equipment like a 35L Rubber Banbury Mixer 125 HP for Sale. Under schemes such as MSME Credit Linked Capital Subsidy Scheme (CLCSS), eligible units receive capital subsidies for technology upgrades.

Additionally, PMEGP (Prime Minister’s Employment Generation Programme) offers financial assistance for new rubber processing units. State-level industrial policies also provide GST rebates, electricity duty exemptions, and interest subsidies. Because of these schemes, entrepreneurs can significantly reduce initial setup costs while improving production capability.

35L Rubber Banbury Mixer 125 HP for Sale – Machine Making Highlights

A 35L Rubber Banbury Mixer 125 HP for Sale features robust construction and industrial-grade components. Key machine-making points include:

Heavy-duty rotors designed for uniform rubber dispersion

125 HP high-efficiency motor for stable torque output

Pneumatic or hydraulic ram for consistent pressure control

Wear-resistant mixing chamber lining

User-friendly control panel for batch accuracy

These features ensure long service life and dependable performance.

Major Industrial Areas to Set Up 35L Rubber Banbury Mixer 125 HP for Sale – Perfect Working Condition

Installing a 35L Rubber Banbury Mixer 125 HP for Sale – Perfect Working Condition works best in established industrial clusters. Major locations include:

Maharashtra – Pune, Aurangabad, and Mumbai rubber hubs

Tamil Nadu – Chennai, Coimbatore, and Hosur

Gujarat – Ahmedabad, Vapi, and Vadodara

Haryana – Faridabad and Gurugram

Punjab – Ludhiana and Jalandhar

These regions offer skilled labor, strong logistics, and raw material availability.

Why Choose vatsntecnic for 35L Rubber Banbury Mixer 125 HP for Sale

When sourcing a 35L Rubber Banbury Mixer 125 HP for Sale, vatsntecnic stands out for reliability and transparency. The company supplies machines that undergo strict inspection and load testing before dispatch. Moreover, vatsntecnic offers technical guidance, installation support, and after-sales assistance.

Because vatsntecnic understands real shop-floor challenges, it recommends machines based on production goals—not just specifications. Competitive pricing, verified machine condition, and honest documentation make vatsntecnic a trusted name in the rubber machinery market.

For More Information Visit Here

You must be logged in to post a review.

Compression Molding

Compression Molding

Reviews

There are no reviews yet.