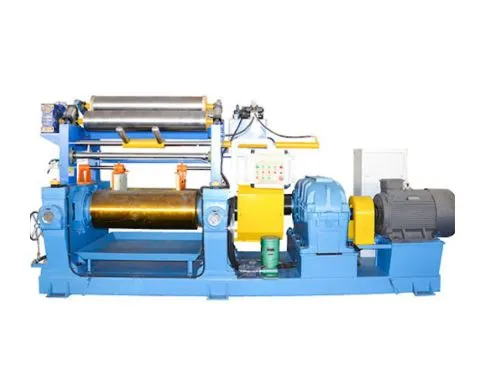

Rubber Vacuum Molding machine in Sikkim Process

Rubber Vacuum Molding in Sikkim for Advanced Industrial Manufacturing

Rubber vacuum molding in Sikkim supports precision-focused industrial manufacturing growth.

Moreover, this technology delivers consistent quality for specialized rubber components.

Therefore, manufacturers adopt this production process for demanding applications.

In addition, controlled molding conditions reduce defects during industrial manufacturing steps.

As a result, equipment production units achieve higher operational stability.Rubber vacuum molding integrates pressure control with advanced heating systems.

Moreover, this approach improves production system development for modern factories.

Therefore, industries benefit from predictable outputs and reduced rework.

In addition, Sikkim provides an emerging base for industrial system production line expansion.This method supports automotive, electrical, and infrastructure industries.

Moreover, manufacturers achieve reliable outcomes through optimized machine making process strategies.

As a result, regional industrial competitiveness improves steadily.Rubber Vacuum Molding Sikkim Using an Optimized Production Process Strategy

Rubber vacuum molding follows a structured and controlled production process.

Moreover, the system removes trapped air during industrial manufacturing steps.

Therefore, molded rubber products achieve better surface finish.

In addition, vacuum control enhances consistency across equipment production units.This technology supports scalable production system development.

Moreover, industries manage complex shapes with greater precision.

As a result, the industrial system production line delivers uniform product quality.Manufacturers also reduce material wastage through optimized machine making process design.

Therefore, operational efficiency improves across multiple industrial sectors.Benefits of Reliable Rubber Manufacturing Systems in Sikkim

Reliable rubber manufacturing systems strengthen industrial performance.

Moreover, proven production practices support long-term growth.Key advantages include:

Moreover, consistent quality improves brand trust

Therefore, reduced downtime supports higher productivity

In addition, efficient production system development lowers operational costs

As a result, equipment production units scale faster

Moreover, streamlined industrial system production lines ensure stability

Therefore, machine making process efficiency increases profitability

These benefits guide manufacturers adopting advanced systems in Sikkim.

Government Support for Rubber Manufacturing Units in Sikkim

Government initiatives encourage trusted supplier development.

Moreover, these schemes strengthen production system development frameworks.Key support initiatives include:

Moreover, MSME registration benefits reduce compliance burden

Therefore, capital subsidies support equipment production units

In addition, tax incentives improve industrial manufacturing steps

As a result, training programs enhance machine making process skills

Moreover, infrastructure grants support industrial system production line setup

These initiatives attract long-term industrial investments.

Major Industrial Areas in Sikkim for Rubber Equipment Production Units

Sikkim offers multiple industrial zones for manufacturing growth.

Moreover, each area supports organized production process operations.Top industrial zones include:

Rangpo Industrial Area

Majhitar Industrial Growth Centre

Jorethang Industrial Estate

Singtam Industrial Area

Rorathang Industrial Growth Hub

These zones promote efficient industrial manufacturing steps.

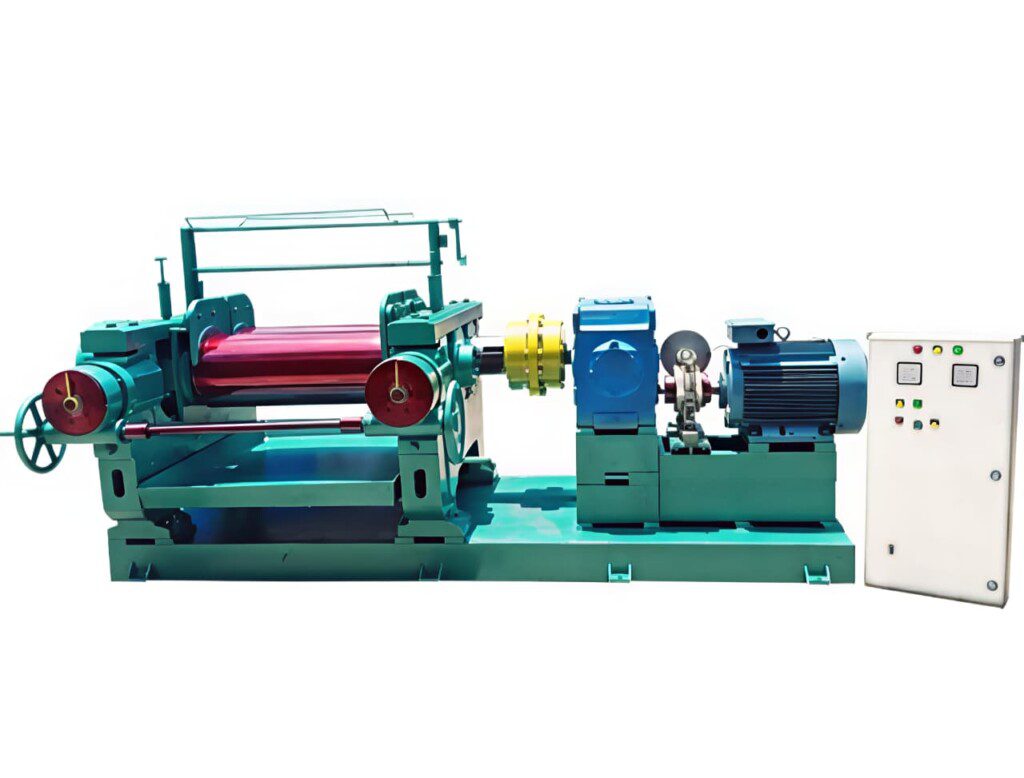

How Rubber Industrial Systems Are Manufactured in Sikkim | Step-by-Step Process

Industrial systems follow a structured machine making process.

Moreover, planning begins with detailed production system development analysis.First, engineers design layouts for the industrial system production line.

Therefore, workflow efficiency improves during industrial manufacturing steps.Next, raw materials undergo quality inspection.

Moreover, this ensures consistency across equipment production units.Then, machining and fabrication start the machine making process.

As a result, components meet technical specifications.Afterward, assembly integrates subsystems into the production process.

Moreover, alignment ensures operational accuracy.Testing validates industrial manufacturing steps.

Therefore, reliability increases before delivery.Finally, installation completes the industrial system production line.

As a result, manufacturers achieve smooth production startup.Why Choose VatsnTecnic for Rubber Vacuum Molding Systems in Sikkim

VatsnTecnic delivers excellence in industrial machine manufacturing.

Moreover, the company focuses on robust production process design.Key strengths include:

Moreover, advanced production system development expertise

Therefore, reliable industrial manufacturing steps execution

In addition, responsive technical support teams

As a result, durable and efficient equipment production units

For more information Visit Here

Compression Molding

Compression Molding