Wanted Uni Drive Bearing Used Rubber Mixing Mill Supplier In India

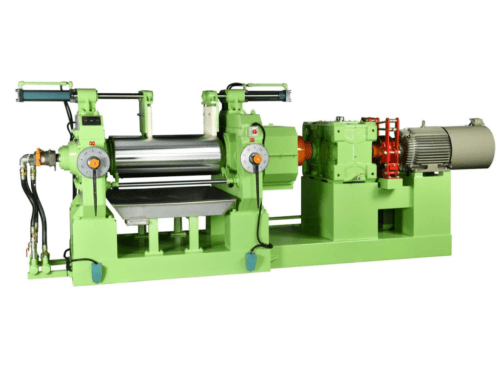

Rubber mixing mills are vital to the rubber industry. They ensure the smooth processing of raw materials into high-quality rubber. These mills have many parts that keep them running. The uni drive bearing is a critical part. Choosing a reliable uni drive-bearing supplier is crucial. Experience them. This choice is key to the efficiency and longevity of your rubber mixing mill. In this guide, we explore the key factors to consider. These factors are important. They matter when seeking a trusted supplier of uni drive-bearings in India.

Uni drive bearings are vital for rubber mixing mills. They give the support and stability the mill’s drive system needs. These bearings help rolls rotate. This rotation ensures rubber compounds mix. A good uni drive bearing boosts the mill’s performance. It raises productivity and cuts downtime.

Key Considerations When Choosing a Uni Drive Bearing Supplier –

1. Quality Assurance:

Look for a supplier with a reputation for delivering high-quality uni drive bearings. Ensure that their products meet industry standards and adhere to stringent quality control measures.

2. Material and Durability:

Uni drive bearings should be manufactured from durable materials to withstand the demanding conditions of rubber mixing mills. Opt for suppliers who use premium materials to ensure longevity and minimal wear and tear.

3. Customization Options:

Every rubber mixing mill may have unique specifications. A reliable supplier should offer customization options to tailor uni-drive bearings to the specific requirements of your mill, ensuring a perfect fit and optimal performance.

4. Technical Expertise:

Choose a supplier with a team of experienced engineers and technical experts. Their knowledge and expertise can provide valuable insights and assistance in selecting the right uni-drive bearings for your rubber mixing mill.

5. After-Sales Support:

A reputable supplier should offer excellent after-sales support, including timely maintenance services, replacement parts, and technical assistance. This ensures that your rubber mixing mill operates at peak efficiency throughout its lifecycle.

6. Cost-Effectiveness:

While cost is a crucial factor, it’s essential to strike a balance between quality and affordability. Avoid compromising on quality for a lower price, as this may lead to increased maintenance costs and downtime in the long run.

Conclusion –

Choosing the right uni-drive bearing supplier is a strategic decision that directly influences the performance and efficiency of your rubber mixing mill. By prioritizing factors such as quality assurance, material durability, customization options, technical expertise, and after-sales support, you can ensure the smooth and productive operation of your rubber processing facility. Take the time to research and collaborate with a trusted supplier, and you’ll reap the rewards of enhanced performance and prolonged equipment life.

For more information Visit Here

Compression Molding

Compression Molding