Rubber Vacuum Molding in Karnataka

Rubber Vaccum Molding in Karnataka: A Complete Guide for Entrepreneurs

Rubber Vaccum Molding is a growing manufacturing method in India. It offers great quality rubber parts for many industries. In this blog, you will learn the benefits of Rubber Vaccum Molding Production. You will also learn about government support for trusted suppliers of Rubber Dispersion Kneader Machines in Delhi. Plus, you will see the major industrial areas for Rubber Vaccum Molding in Karnataka. Finally, you will discover why vatsntecnic is a top choice for your business.

What Is Rubber Vaccum Molding Production Process?

Rubber Vacuum Molding is a manufacturing technique that utilizes heat and pressure inside a vacuum chamber where air and gases are removed from rubber material, improving the quality and strength of the finished products.

It can be used to create components that will have complex shapes, with a low level of defects, and it is a major manufacturing method used by most industries. Some of the major industries that use this technique are automotive, aerospace, and electronics.

Benefits of Setting Up Rubber Vaccum Molding Production Process

The advantages of setting up a Rubber Vaccum Molding unit for manufacturers consist of:

Improved Product Quality

By eliminating trapped air, Rubber Vaccum Molding minimizes the number of voids and bubbles in the finished rubber part resulting in a more uniform and aesthetically pleasing product.

Decreased Material Waste

Since the molding process is conducted in a vacuum, the number of defective parts produced has been decreased, therefore decreasing the amount of raw material wasted. This results in significant monetary savings on the purchase of expensive rubber compounds.

Increased Mechanical Properties

Parts produced using the vacuum molding method, in comparison to those produced using traditional methods, exhibit superior tensile and flexural strength, along with the ability to resist tearing, cracking and distortions.

Quicker Manufacturing Cycle

Due to the rapid curing and heating of rubber parts via vacuum molding machines, manufacturers can create more finished products each day meeting the increasing demands of the industry.

Highly Versatile Product Applications

With the capability to manufacture a large range of products across different industries, Rubber Vacuum Molding can be utilized to produce automotive seals, medical gaskets and industrial components amongst others.

Lower rework and expenses

Fewer defective parts produced via rubber vacuum molding equates to less rework required; therefore lowering the total cost of production over time.

Environmentally friendly production.

Emissions generated during the process of curing rubber parts are dramatically reduced via vacuum molding. In addition, the amount of energy consumed to produce one unit of each finished part is significantly reduced as compared with other methods of production.

Government Scheme for Trusted Suppliers of Rubber Dispersion Kneader Machines in Delhi

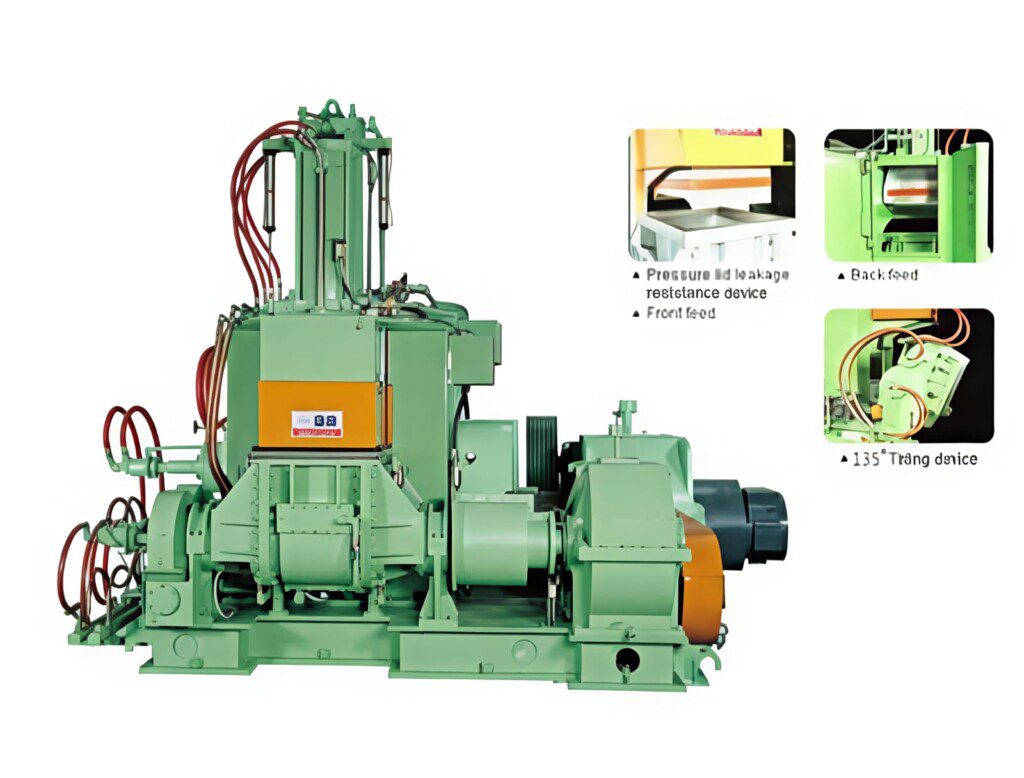

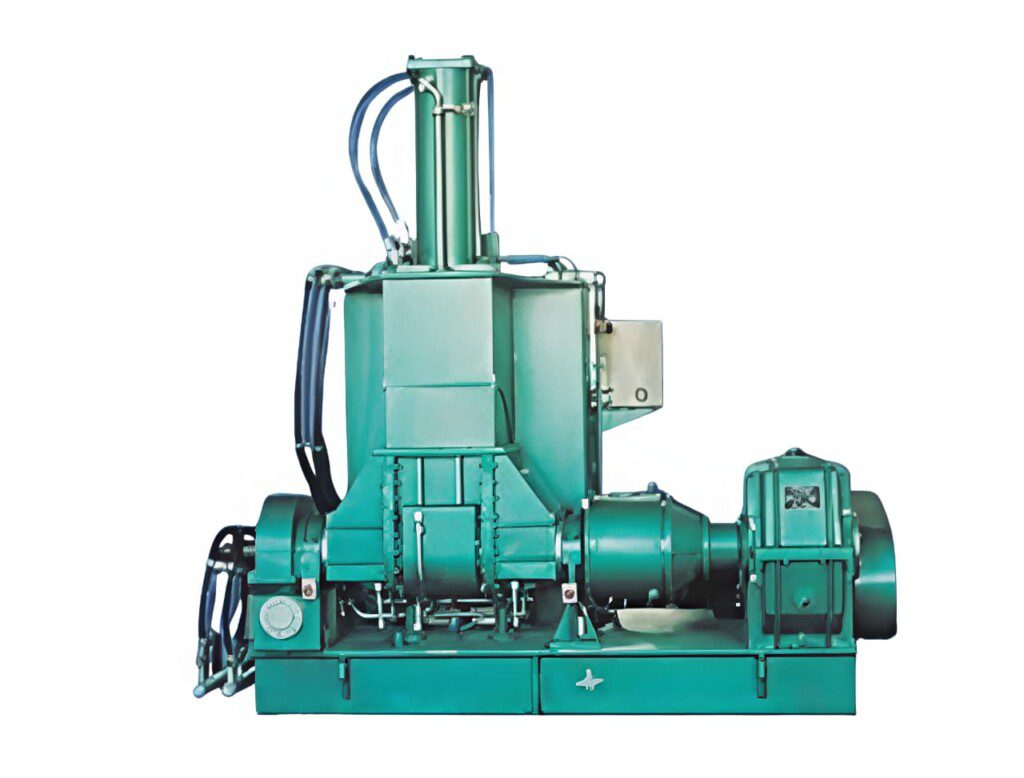

If you plan to set up Rubber Vaccum Molding production, you may need a Rubber Dispersion Kneader Machine. The Indian government supports manufacturing units with various schemes. Below are five key points about support for trusted machine suppliers in Delhi:

1. Subsidy Support for MSMEs

The government gives subsidies to MSMEs. This helps buy capital equipment like dispersion kneaders. Subsidy rates may vary by scheme.

2. Credit Linked Capital Subsidy Scheme (CLCSS)

Under CLCSS, industries get financial help. It covers part of the machine cost. Your investment burden reduces.

3. Technology Upgradation Funds

Funds support upgrading to modern machines. These include energy-efficient kneader units. This improves production quality.

4. GST and Tax Benefits

Machines procured under government schemes may get GST relief. This reduces overall tax burden for businesses.

5. Vendor Development Programs

Government supports trusted suppliers through vendor fairs. This increases market reach for Delhi-based machine makers.

These government programs make it easier to set up quality Rubber Vaccum Molding units. They also promote growth and competitiveness.

Major Industrial Areas for Rubber Vaccum Molding in Karnataka

Karnataka is a leading state for manufacturing. It offers strategic locations for Rubber Vaccum Molding industries. Below are five key industrial areas:

1. Bangalore Industrial Corridors

Bangalore has advanced industrial parks. These have strong logistics and skilled workforce. It is ideal for rubber molding startups.

2. Mysore Rubber Cluster

Mysore hosts many rubber product manufacturers. It offers raw material availability. This lowers your supply chain cost.

3. Belgaum Engineering Hub

Belgaum has strong engineering support. You can find tooling and part suppliers nearby. This boosts production efficiency.

4. Mangalore SEZ & Ports

Mangalore has a Special Economic Zone (SEZ). It also has port access for export. This is great for global rubber products.

5. Hubli-Dharwad Industrial Growth

Hubli-Dharwad offers growing industrial estates. It has affordable land and electricity. This reduces operation costs.

These areas have robust infrastructure. They also provide easy access to markets across India and abroad.

Rubber Vaccum Molding Synonyms (to Boost SEO)

To improve search visibility, here are synonyms used in this blog:

- Vacuum Rubber Forming

- Rubber Vacuum Compression

- Vacuum Cured Rubber Production

- Vacuum Molding of Rubber Parts

- Rubber Vacuum Manufacturing Process

Use these terms in your web pages to rank better in search.

Why Choose Rubber Vaccum Molding Over Other Methods?

Rubber Vaccum Molding gives distinct advantages. The vacuum setup helps remove air bubbles. It also ensures uniform curing and precise shapes.

When you compare with traditional compression or injection molding, vacuum molding:

- Gives cleaner edges

- Reduces part rejection rate

- Improves heat transfer during curing

- Works for high-performance rubber compounds

This makes it ideal for technical products.

Why Choose vatsntecnic for Your Rubber Vaccum Molding Needs?

Your choice of supplier matters. vatsntecnic stands out for many reasons. Here are the top points:

1. Industry Expertise

vatsntecnic has years of experience in rubber machinery. Their team knows your production challenges.

2. Quality Vacuum Molding Systems

They provide reliable Rubber Vaccum Molding machines. These machines help you meet global quality standards.

3. After-Sales Support

vatsntecnic offers quick technical help. You get training and maintenance services.

4. Affordable Pricing

They offer competitive rates without compromising quality. This helps your ROI grow faster.

5. Trusted Supplier Network

They have a strong supplier base for parts and consumables. This ensures uptime for your plant.

Choosing vatsntecnic gives you a partner, not just a machine vendor. They focus on long-term success.

Tips for Starting Rubber Vaccum Molding in Karnataka

Before you start, consider these practical tips:

• Conduct Market Research

Identify your target industries. Know the demand for specific rubber parts.

• Choose the Right Location

Pick zones with reliable power and transport. It makes production smoother.

• Plan for Skill Development

Train your workforce in vacuum molding operations. Skilled operators reduce defects.

• Connect with Government Schemes

Apply early for subsidies and tax benefits. This reduces your investment risks.

• Partner with a Trusted Supplier

Work with a supplier like vatsntecnic who supports you long-term.

Conclusion

Setting up a Rubber Vaccum Molding unit in Karnataka can be highly profitable. You benefit from improved product quality, lower defects, and fast production. With government schemes for trusted suppliers of Rubber Dispersion Kneader Machines in Delhi, your startup costs are more manageable. Karnataka’s industrial hubs provide excellent infrastructure and market access.

If you need a trusted partner for your rubber molding machinery, vatsntecnic offers quality, service, and industry expertise. Start your Rubber Vaccum Molding journey today!

For more information Visit Here

Compression Molding

Compression Molding