Rubber Molding Hydraulic Press Dealer in Delhi | New & Used Press Supplier

Rubber Molding Hydraulic Press Dealer in Delhi | Used & New Solutions

Delhi has emerged as a leading destination for industrial machinery sourcing in India. Rubber Molding Hydraulic Press Manufacturers across rubber, footwear, automotive, and polymer sectors rely on this market for dependable molding equipment. Businesses can easily find new, used, and refurbished solutions with technical support and fast availability.

This guide explains essential information about hydraulic molding equipment, its uses, advantages, and sourcing options in Delhi’s industrial ecosystem.

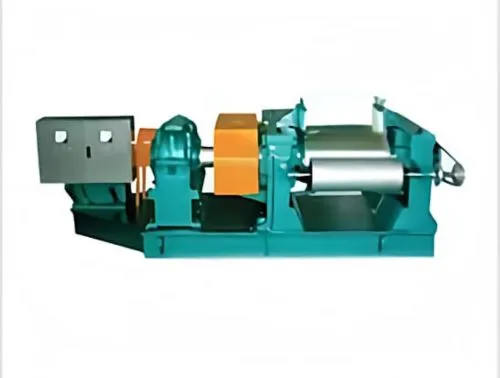

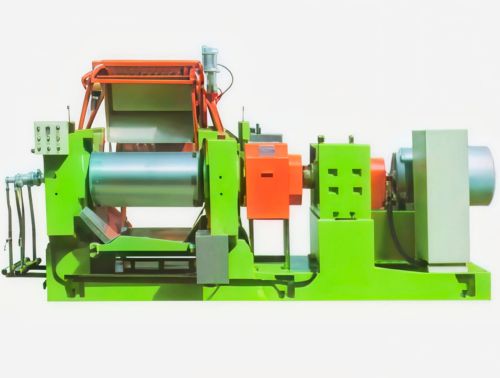

Understanding Rubber Molding Press Technology

A rubber molding press is an industrial machine that shapes raw rubber compounds using controlled pressure and heat. It helps manufacturers achieve consistent product dimensions and stable curing results. Operators can adjust pressure and temperature based on product requirements.

Such machines support both standard and customized rubber component manufacturing across multiple industries.

Common Industrial Applications

Hydraulic molding equipment supports a wide range of production needs. Manufacturers commonly use these machines for:

Footwear soles and rubber slippers

Seals, gaskets, and O-rings

Rubber sheets and mats

Bushes, couplings, and vibration parts

Medical and silicone components

This flexibility makes hydraulic presses suitable for small workshops and large factories alike.

Key Advantages for Rubber Manufacturers

Modern hydraulic systems provide several operational benefits compared to older mechanical presses. These advantages improve productivity and long-term reliability.

Precise pressure control for uniform output

Consistent product quality across batches

Lower operating and maintenance costs

Energy-efficient performance

High output capability

Long service life with proper maintenance

These benefits help manufacturers meet quality standards while controlling production expenses.

Available Machine Configurations

Different press configurations suit different manufacturing goals. Buyers can select machines based on automation level, product complexity, and output volume.

Compression presses for sheets and industrial parts

Transfer presses for precision rubber components

Vacuum presses for bubble-free molded products

Automatic presses with PLC control

Semi-automatic machines for cost-effective operations

Each configuration supports specific production requirements.

Why Delhi Is a Preferred Machinery Market

Delhi NCR has become a strong industrial machinery hub due to its infrastructure and supplier network. Areas like Faridabad, Noida, Ghaziabad, and Gurugram support manufacturing growth.

Key reasons include easy access to refurbished equipment, skilled technicians, spare parts availability, and quick logistics. Buyers also benefit from inspection-ready stock and refurbishment expertise.

Sourcing Used and Refurbished Machines

Many manufacturers prefer refurbished presses due to cost savings and shorter delivery timelines. Reliable suppliers test machines thoroughly before dispatch of Rubber Molding Hydraulic Press.

Commonly available options include presses ranging from small capacities to heavy-duty vacuum and automatic systems. These machines often deliver strong performance when maintained correctly.

Why Choose Vatsn Tecnic

Vatsn Tecnic supplies industrial machinery solutions with a focus on reliability and service support. The company offers new, used, and reconditioned equipment tailored to customer needs.

Key strengths include technical assistance, installation support, maintenance services, and pan-India delivery. Clients can inspect machines before purchase and receive customized solutions based on production requirements.

Service coverage includes Delhi, Mumbai, Chennai, Kolkata, Bengaluru, Hyderabad, Pune, and major industrial regions.

Compression Molding

Compression Molding