Rubber Dispersion Kneader in Chennai | Maharashtra Manufacturing

⭐ Rubber Dispersion Kneader in Chennai – Manufacturing, Setup & Benefits (2025 Guide)

A Rubber Dispersion Kneader in Chennai is becoming a valuable investment for rubber manufacturers in 2025. The city offers strong industrial growth, supply chain access, and skilled manpower for machinery setup. With rising demand in the rubber and polymer industry, Chennai provides the right environment for efficient production and compounding operations.

Industrial Growth and Demand in Chennai

Chennai has emerged as a growing hub for rubber product manufacturing. The market supplies to automotive, cable, footwear, engineering, and conveyor belt sectors. Because of this, high-quality rubber mixing machines are now essential for consistent compound output.

A kneader machine helps:

- Maintain uniform mixing quality

- Reduce production errors

- Improve batch stability

- Support large-scale rubber compounding

Benefits of Installing a Rubber Kneader Machine

Setting up a kneader in Chennai offers several practical advantages:

- Access to trained machine operators

- Strong logistics and port connectivity

- Easy availability of raw rubber and additives

- Growth in automotive and industrial rubber supply

- Suitable infrastructure for medium and large units

Manufacturers also save time and reduce dependency on manual labor through semi-automatic and automatic kneader models.

How Kneader Machines Improve Manufacturing Quality

A kneader machine ensures better control over rubber mixing. It manages temperature, pressure, and compound blending to meet industry standards. As a result, companies experience reduced wastage and increased reliability in final products.

Key improvements include:

- Uniform dispersion of fillers

- Better compound texture and bonding

- High batch output for commercial scale

- Faster cycle time in production lines

Government Support & Subsidy Options

Chennai offers good opportunities through MSME and industrial support schemes. These programs help new and existing units grow.

Available benefits may include:

- Subsidized interest rates for machinery purchase

- MSME loan support through government banks

- Skill training for production and maintenance staff

- Incentives for adopting new technology

- Export support for qualified rubber product units

Note: Actual eligibility depends on business registration and approval.

Best Industrial Areas to Start a Rubber Unit in Chennai

Several industrial zones make machinery installation and material sourcing easier:

- Sriperumbudur Industrial Area

- Ambattur Industrial Estate

- Oragadam Industrial Hub

- Guindy Industrial Estate

- Thirumazhisai Industrial Zone

These locations offer strong logistic access, trained workforce, and industrial infrastructure.

Manufacturing Workflow: Step-by-Step Mixing Process

Typical kneader production steps include:

- Load rubber polymer and additives

- Adjust temperature and pressure settings

- Kneading chamber mixes compounds uniformly

- Discharge system releases the final compound

- Quality testing ensures production accuracy

This workflow helps achieve stable performance in rubber products like seals, cables, hoses, footwear, and belts.

Kneader Machines for Conveyor Belt Materials

Conveyor belt materials require strong bonding and durability. A kneader supports this by creating a smooth rubber mass suitable for molding and extrusion. It improves adhesion strength and surface performance, making it useful for heavy industry applications.

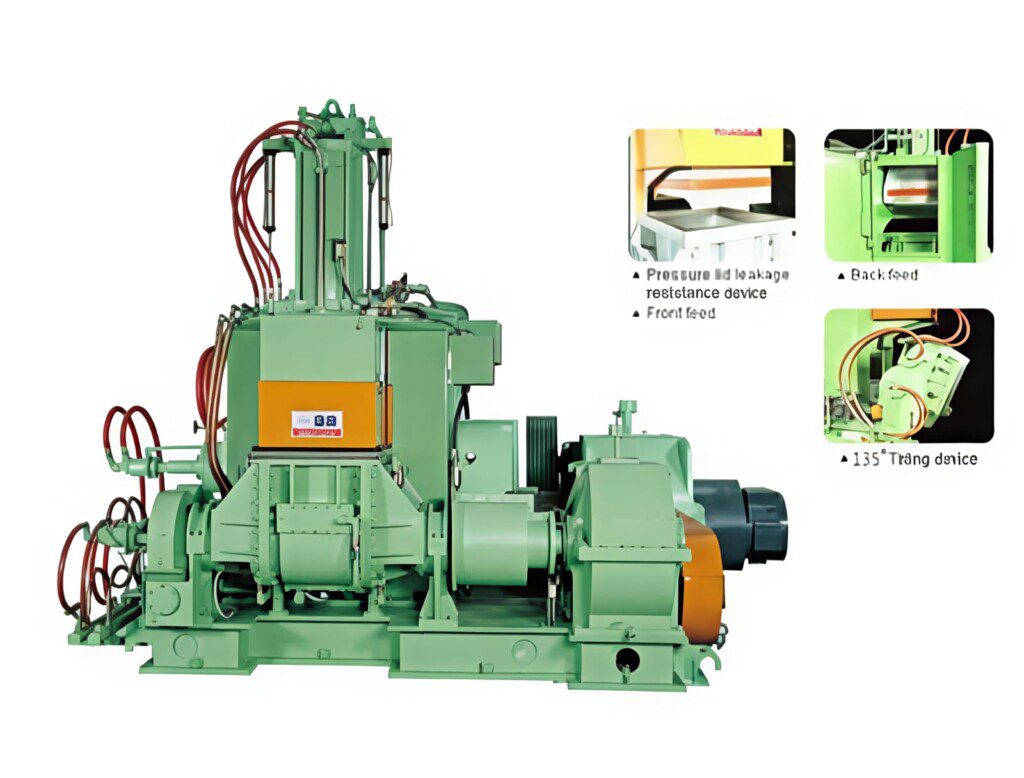

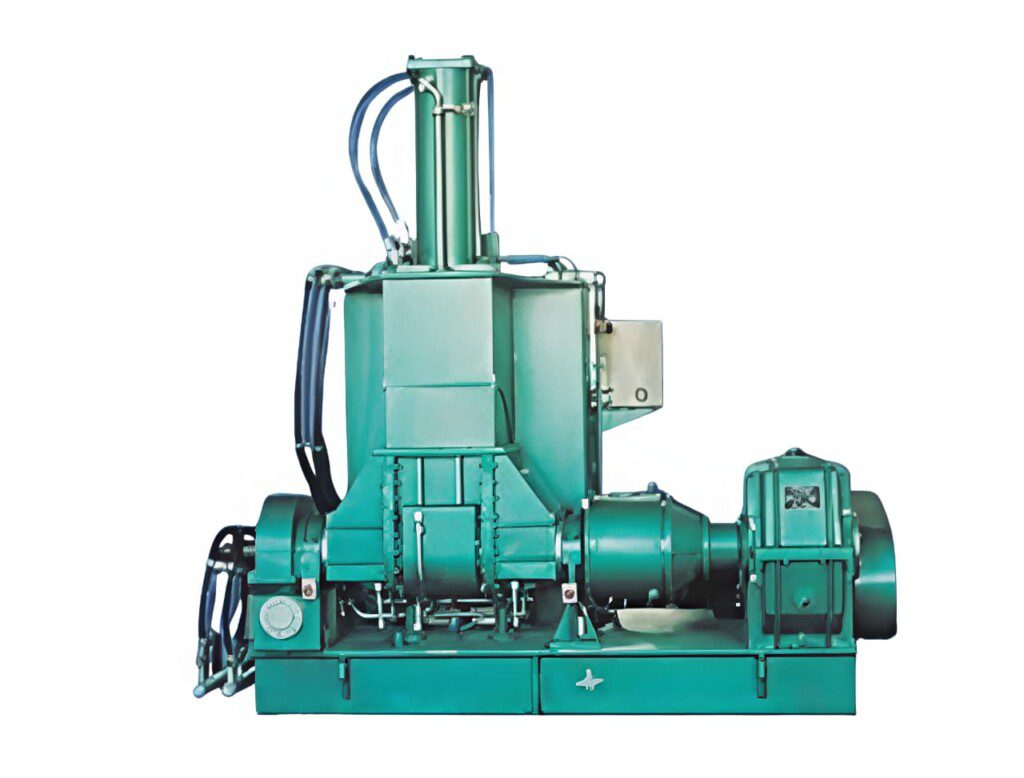

Why Choose Vatsn Tecnic

Vatsn Tecnic provides reliable kneader machines designed with industrial safety and performance standards. The company supports customers with setup assistance, operator training, maintenance guidance, and after-sales service.

Manufacturing process includes:

- High-grade steel fabrication structure

- Balanced rotors for vibration-free performance

- Precision mixing chamber design

- Electrical automation and safety control

- Final testing before delivery

This ensures long-term stability for production units.

Conclusion

A Rubber Dispersion Kneader in Chennai is a profitable investment for companies looking to scale rubber product manufacturing. The region provides strong infrastructure, growing demand, and government support. By choosing a trusted machinery supplier, manufacturers achieve better output, consistent compound quality, and improved production efficiency.

For professional installation and machine guidance, Vatsn Tecnic stands as a reliable partner for the rubber industry.

For more information Visit Here

Compression Molding

Compression Molding