Rubber Compression Molding in Odisha

Rubber Compression Molding in Odisha for Modern Industrial Manufacturing

Rubber Compression Molding in Odisha supports growing industrial demand across multiple sectors.

Moreover, Odisha offers strong infrastructure for a stable production process.

Therefore, manufacturers prefer Odisha for efficient industrial manufacturing steps.

In addition, skilled labor improves every machine making process.

As a result, equipment production units deliver consistent output quality.

Moreover, regional policies encourage industrial system production line expansion.

Rubber components serve automotive, mining, and electrical industries widely.

Therefore, compression molding remains a preferred production system development method.

In addition, controlled pressure ensures uniform rubber product formation.

As a result, manufacturers achieve cost-effective industrial scalability.

Benefits of a Reliable Production Process in Maharashtra for Industrial Manufacturing Steps

Although Odisha grows rapidly, Maharashtra still supports advanced production process benchmarks.

Moreover, industries compare Maharashtra models during production system development.

- Moreover, reliable industrial manufacturing steps reduce operational downtime

- Therefore, a stable production process improves output consistency

- In addition, optimized machine making process lowers energy consumption

- As a result, equipment production units achieve higher efficiency

- Moreover, industrial system production line automation increases safety

- Therefore, skilled manpower enhances long-term production system development

These benefits guide manufacturers planning Rubber Compression Molding in Odisha expansion.

Government Scheme for Setting Up a Trusted Supplier Using Industrial Manufacturing Steps

Government initiatives support production process reliability across Indian states.

Moreover, Odisha promotes industrial manufacturing steps through financial incentives.

- Moreover, MSME schemes support equipment production units funding

- Therefore, capital subsidies improve machine making process investment

- In addition, tax rebates assist industrial system production line growth

- As a result, export incentives boost production system development

- Moreover, training programs enhance industrial manufacturing skills

Such schemes strengthen supplier credibility within Rubber Compression Molding in Odisha.

Major Industrial Areas for Setting Up Production System Development Units

Strategic locations support a smooth production process and logistics flow.

Moreover, Odisha offers multiple industrial zones for equipment production units.

- Moreover, Kalinganagar supports heavy industrial system production line projects

- Therefore, Paradip enables export-oriented industrial manufacturing steps

- In addition, Rourkela offers skilled workforce for machine making process

- As a result, Angul attracts power-intensive production system development

- Moreover, Bhubaneswar supports technology-driven equipment production units

These zones suit Rubber Compression Molding in Odisha expansion plans.

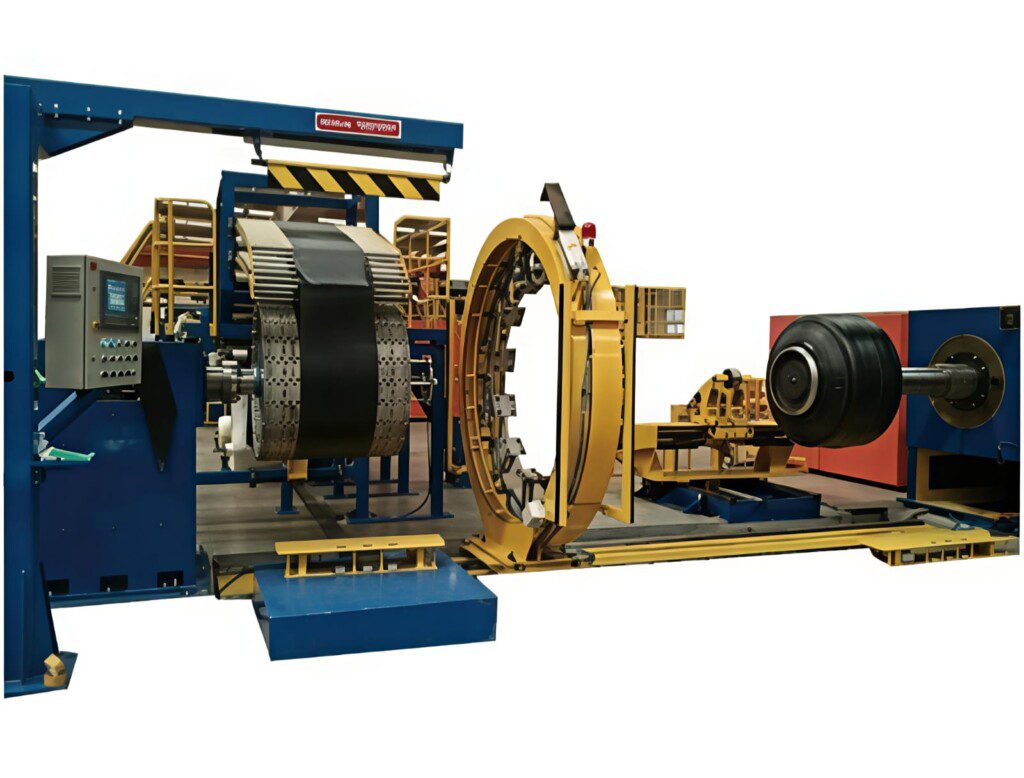

How Industrial Systems Are Made | Step-by-Step Manufacturing Process Development

Industrial success depends on a structured production process workflow.

Moreover, each stage strengthens industrial manufacturing steps reliability.

Raw Material Selection in the Production Process

Moreover, engineers select rubber compounds based on performance requirements.

Therefore, material consistency ensures smooth industrial system production line flow.

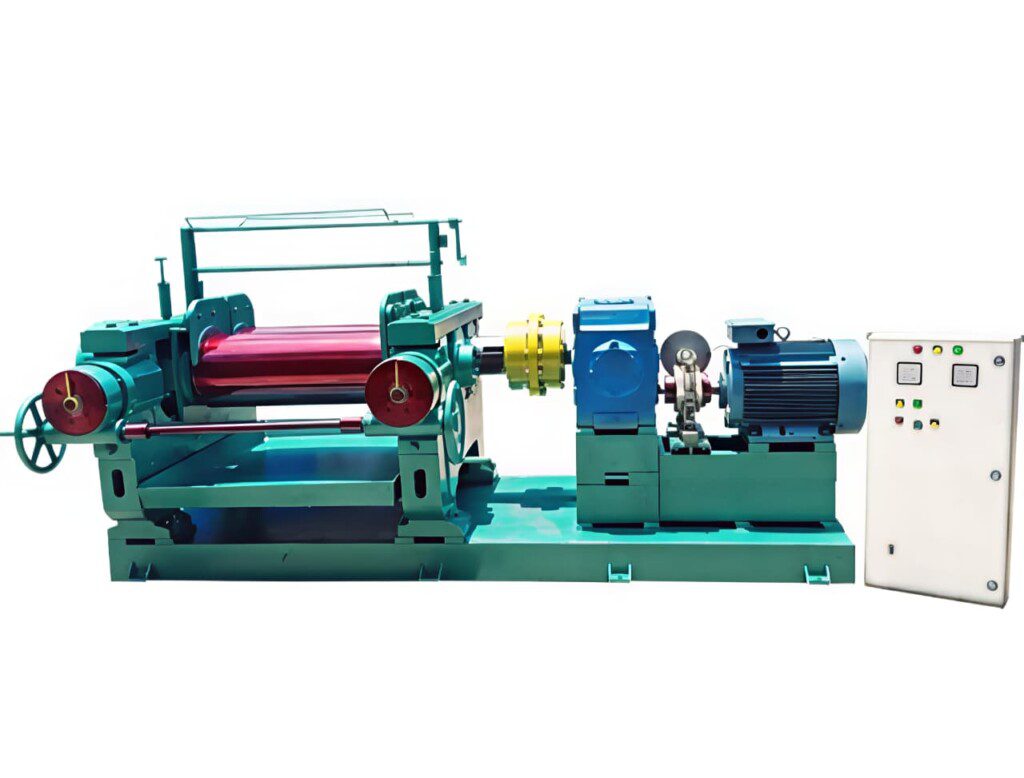

Mold Design During Machine Making Process

In addition, designers create precise molds using advanced software.

As a result, equipment production units maintain dimensional accuracy.

Heating and Compression in Industrial Manufacturing Steps

Moreover, machines apply controlled heat and pressure.

Therefore, rubber fills molds evenly during the production process.

Cooling Stage in Production System Development

In addition, controlled cooling stabilizes rubber structure.

As a result, industrial system production line defects reduce significantly.

Trimming and Inspection in Equipment Production Units

Moreover, operators remove excess material carefully.

Therefore, final inspections ensure compliance with industrial manufacturing standards.

This step-wise approach strengthens Rubber Compression Molding in Odisha reliability.

Why Choose VatsnTecnic? for Industrial Machine Manufacturing Process Excellence

VatsnTecnic supports advanced production process implementation.

Moreover, the company delivers robust industrial manufacturing steps.

- Moreover, precision machines enhance industrial system production line efficiency

- Therefore, expert engineers support complete production system development

- In addition, reliable components improve machine making process lifespan

- As a result, equipment production units achieve consistent quality

- Moreover, responsive service ensures operational continuity

Delhi Government Schemes Supporting Industrial Manufacturing Steps

Delhi policies also inspire nationwide production system development models.

- Moreover, capital assistance supports machine making process upgrades

- Therefore, interest subsidies reduce equipment production units costs

- In addition, startup incentives strengthen industrial manufacturing steps

- As a result, skill programs enhance production process expertise

- Moreover, digital initiatives improve industrial system production line monitoring

VatsnTecnic aligns solutions with these policy-driven industrial benchmarks.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For more information Visit Here

Compression Molding

Compression Molding