2 Nos. Calendar Available – Sizes 8×24 and 6×18

2 Nos. Calendar Available – Sizes 8×24 and 6×18 | Working Condition

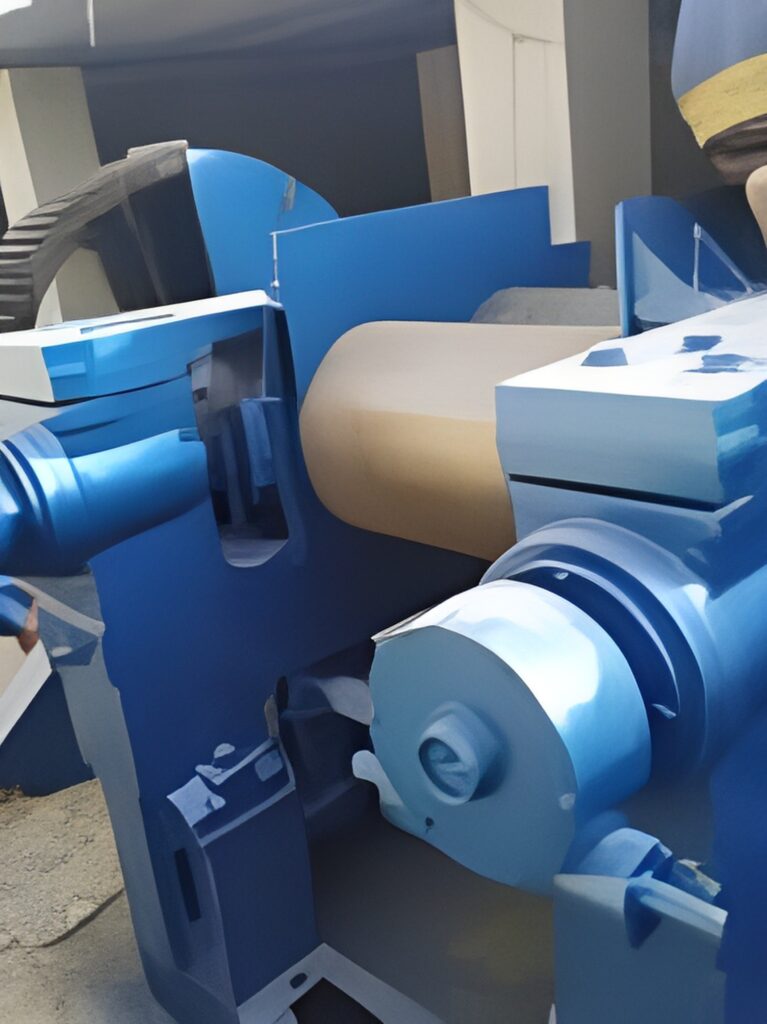

The 2 Nos. Calendar Available – Sizes 8×24 and 6×18 delivers reliable performance for rubber and polymer production lines. These machines is Calendar Machine 8×24 and 6×18 and operate in perfect working condition. They produce stable output and smooth sheets. Therefore, manufacturers reduce risk and improve uptime.

Moreover, this dual-calendar setup fits both small and mid-sized plants. It also supports faster changeovers. As a result, productivity increases while labor use drops.

Benefits of Setting Up 2 Nos. Calendar Available – Sizes 8×24 and 6×18

The 2 Nos. Calendar Available – Sizes 8×24 and 6×18 provides strong operational benefits.

First, it increases production speed. Two machines run together. So, output rises without extra floor space.

Second, it improves product quality. The rollers apply even pressure. Therefore, sheet thickness remains uniform.

Third, it lowers investment cost. These used units in working condition reduce capital spending. Hence, businesses achieve faster returns.

Fourth, it offers flexibility. Different widths and materials process easily. So, your product range expands.

Finally, it saves power. Well-serviced rollers require less energy. As a result, operational costs stay low.

Why 2 Nos. Calendar Available – Sizes 8×24 and 6×18 Fits Your Line

This equipment integrates easily into existing layouts.

Moreover, the compact design supports efficient space use. So, planning becomes easier.

In addition, spare parts remain widely available. Therefore, maintenance stays simple.

Also, operators learn quickly. Hence, training time reduces.

These advantages make the system ideal for industries using the Calendar Machine 8×24 and 6×18.

Government Scheme for 2 Nos. Calendar Available – Sizes 8×24 and 6×18 Making

Several government programs support such manufacturing setups:

• MSME Subsidy helps with machinery upgrades

• Credit Linked Capital Subsidy reduces loan pressure

• State Industrial Policies offer tax benefits

• Skill India supports worker training

• Export Promotion Schemes support overseas sales

Therefore, setting up becomes more affordable and secure.

Major Industrial Areas to Set Up Manufacturing

The right location improves success:

• Gujarat offers strong polymer networks

• Maharashtra provides skilled labor

• Tamil Nadu supports rubber industries

• Uttar Pradesh offers low-cost land

• Karnataka ensures strong logistics

Thus, businesses gain speed and supply chain strength.

Manufacturing Steps of Used Machines – Perfect Working Condition

First, technicians inspect roller alignment.

Next, they service all bearings.

Then, they lubricate moving parts.

After that, they calibrate pressure systems.

Finally, they run trial tests to verify performance.

This process ensures each unit works smoothly.

Quality Output from the System

This setup delivers high-precision sheet finishing.

Moreover, temperature control stays stable. So, materials move smoothly.

In addition, the rollers maintain a uniform nip. Hence, product surface remains even.

These features support industries that rely on the Calendar Machine 8×24 and 6×18.

Why Choose vatsntecnic

vatsntecnic supplies trusted industrial equipment.

We inspect every unit before delivery.

We provide full technical reports.

We support installation and setup.

We offer after-sales service.

We manage safe transportation.

Therefore, your investment stays protected.

Long-Term Value

This machinery supports long-term production growth.

It handles product upgrades easily.

It resists wear due to strong construction.

It delivers stable performance year after year.

Thus, businesses enjoy lasting profitability.

For More Information Visit Here

You must be logged in to post a review.

Compression Molding

Compression Molding

Reviews

There are no reviews yet.