Buy | Sell Used Rubber Compound Mixing Mill 22X60 Motor 125 Hp

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

|

Overall dimension(mm)

|

L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

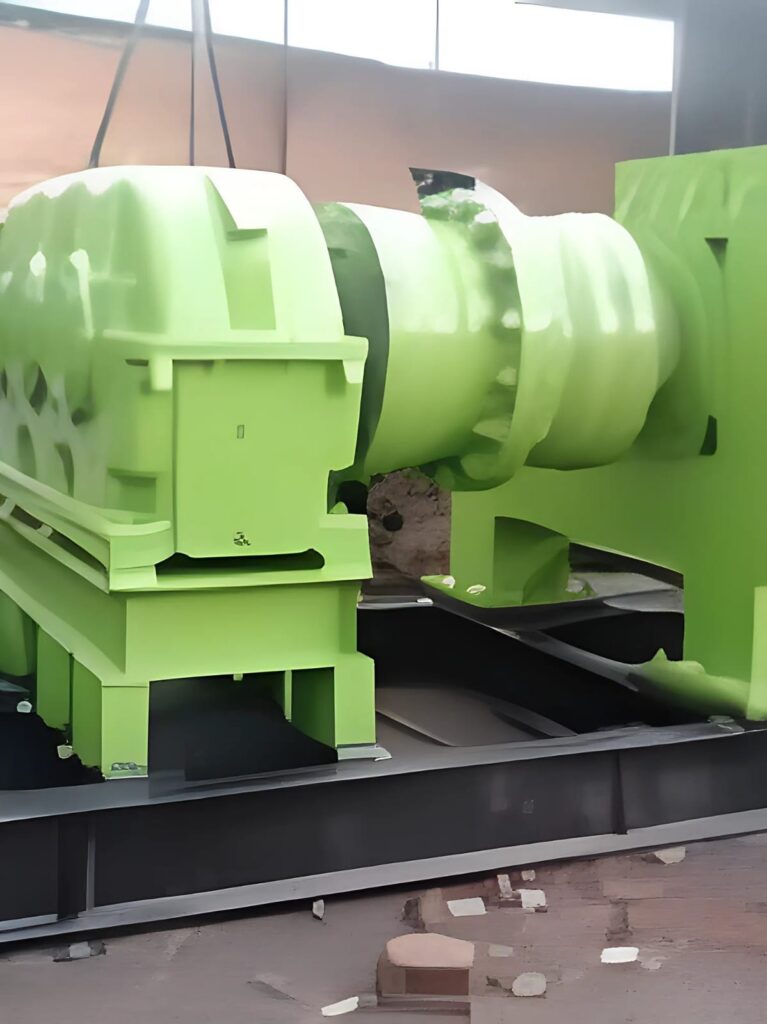

Introducing the ultimate solution for your rubber processing needs – the 22 X 60 Rubber Compound Mixing Mill with a robust 125 HP motor. Whether you’re in the market to buy or sell, Vatsn Tecnic has got you covered.

Product Features –

1. Efficient Mixing: This mixing mill ensures thorough and efficient blending of rubber compounds, vital for achieving optimal product quality.

2. Reliable Power: Equipped with a powerful 125 HP motor, this machine delivers consistent performance, ensuring smooth operation and high productivity.

3. Durable Construction: Built to last, this mixing mill boasts sturdy construction, capable of withstanding the rigors of continuous use in industrial environments.

4. Versatile Application: Suitable for a wide range of rubber compounds, including natural rubber, synthetic rubber, and various additives, making it versatile for diverse manufacturing needs.

Uses of Rubber Compound Mixing Mill –

Rubber compound mixing mills play a crucial role in the rubber manufacturing process. Here’s how they benefit your operations:

1. Homogeneous Mixing: Achieve uniform dispersion of ingredients, ensuring consistent properties and quality in the final rubber product.

2. Customization: Tailor rubber compounds to meet specific requirements such as hardness, elasticity, and chemical resistance, catering to various industrial applications.

3. Reduced Processing Time: Streamline production processes with efficient mixing, minimizing batch-to-batch variations and optimizing overall manufacturing efficiency.

4. Quality Assurance: Maintain stringent quality control by precisely controlling mixing parameters, leading to fewer defects and improved product performance.

Why Choose Vatsn Tecnic?

Vatsn Tecnic stands out as your trusted partner for buying or selling used rubber compound mixing mills. Here’s why:

i) Nationwide Reach: With a presence in major cities across India, including Delhi, Mumbai, Chennai, Bangalore, and more, Vatsn Tecnic ensures convenient access to quality equipment and services.

ii) Comprehensive Support: Beyond transactions, Vatsn Tecnic offers a suite of services, including servicing, maintenance, manpower provision, annual maintenance contracts, and consultancy for business expansion, ensuring a seamless experience from purchase to operation.

iii) Quality Assurance: Every product undergoes rigorous inspection to guarantee reliability and performance, giving you peace of mind with your investment.

Elevate your rubber manufacturing capabilities with the 22 X 60 Rubber Compound Mixing Mill from Vatsn Tecnic. Whether you’re upgrading your equipment or seeking a reliable buyer, trust Vatsn Tecnic for unparalleled service and expertise.

For more information Visit Here

Compression Molding

Compression Molding