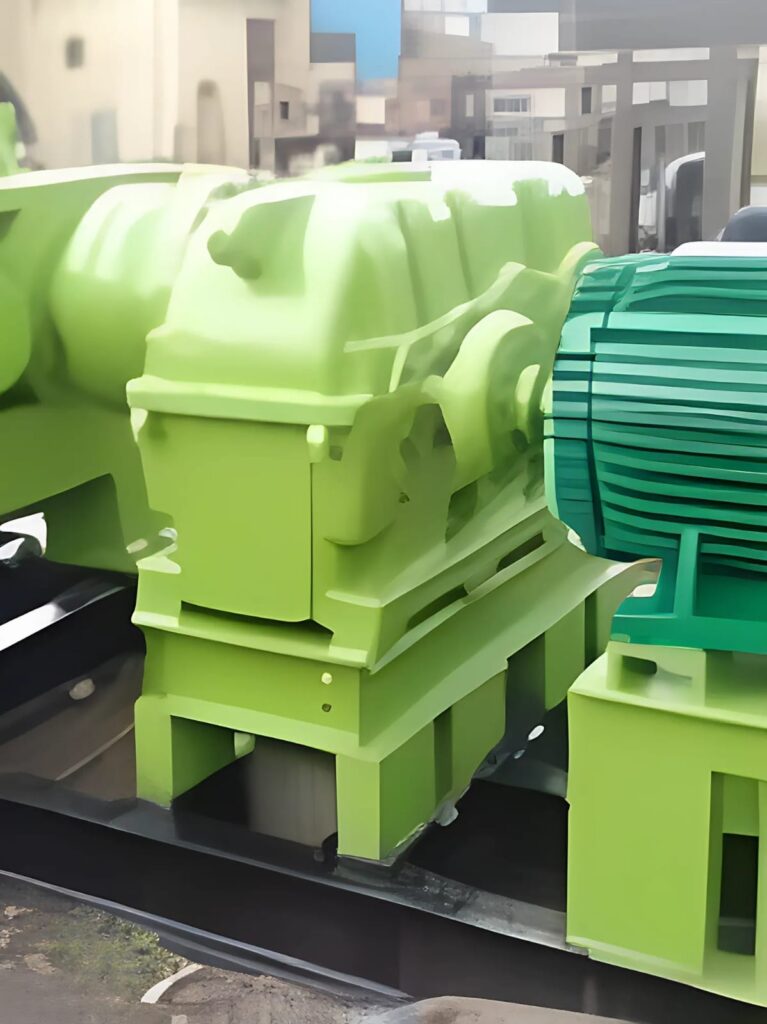

RUBBER RECLAIM MACHINERY

Buy|Sell Used Rubber Reclaim Plant Machinery

- High-Quality Reclaiming: Our machinery is engineered to efficiently break down rubber materials, reclaiming and refining them into high-quality, reusable compounds. This process ensures minimal waste and maximum utilization of rubber resources.

- Advanced Technology: Equipped with the latest technological advancements, our reclaim plant machinery boasts precision in processing, ensuring consistency in output quality. Its intelligent design minimizes energy consumption while maximizing output, making it environmentally friendly and cost-efficient.

- Customizable Configurations: Our machinery offers versatile configurations to cater to various types of rubber materials and processing needs. Whether dealing with tires, conveyor belts, or other rubber products, our reclaim plant machinery can be tailored to suit specific requirements.

- Robust and Durable Build: Built with robust materials and components, our machinery guarantees durability and longevity. It operates seamlessly under demanding conditions, delivering reliable performance for continuous and uninterrupted processing.

- User-Friendly Interface: Designed with user convenience in mind, the machinery features an intuitive interface that simplifies operation and maintenance. This user-friendly interface ensures ease of use for operators, reducing downtime and enhancing productivity.

- Environmental Sustainability: By efficiently reclaiming rubber materials, our machinery contributes significantly to environmental conservation by reducing waste and the need for new raw materials.

- Cost-Efficiency: Recycling rubber through our machinery reduces production costs associated with acquiring new materials, offering a cost-effective solution for businesses.

- Quality Output: The reclaim plant machinery guarantees consistent and high-quality output, meeting industry standards and ensuring reliable performance of recycled rubber compounds.

- Automotive industry: for recycled tire compounds

- Industrial applications: in manufacturing various rubber products

- Environmental initiatives: for sustainable resource utilization

Pre-Owned Rubber Refiner Mill Size 21 X 24 X 36

Rebuilt Rubber Refiner Mill Available for Purchase

| Working diameter of rolls(mm) | φ400front roller φ480rear roller | φ450front roller φ510rear roller | φ480front roller φ610rear roller |

| Roll casting process | centrifugal composite casting | centrifugal composite casting | centrifugal composite casting |

| Roll cooling mode | Around the borehole cooling | Around the borehole cooling | Around the borehole cooling |

| The surface of the roll material | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy |

| Working length of the roll(mm) | 650 | 800/1000 | 800/1000/1200 |

| After the roller line speed(m/min) | 32.94(optional) | 49/55.2/63.4(optional) | 57.5-75.1(optional) |

| Front and rear roller line speed ratio | 1.27-1.815(optional) | 1.38/1.82/2(optional) | 1.27-1.815(optional) |

| Production capacity(kg/h) | 300 | 360 | 500-800 |

| Motor power(kw) | 55 | 55 | 75/90 |

| Roller spacing adjustment range(mm) | 0.1-15 | 0.1-15 | 0.1-15 |

| Reducer | ZSY hard-tooth face gear | ZSY hard-tooth face gear | ZSY hard-tooth face gear |

| Bearing type | the double spherical roller bearing | the double spherical roller bearing | the double spherical roller bearing |

| Dimensions of LxWxH(mm) | 4750x2300x1835 | 4060x2200x1470 | 5070x2800x1978 |

| Quality(kg) | about 10500 | about 12800 | about 20000 |

Refurbished Steam Vulcaniser 1200×3600 for Sale

Key Specifications / Highlights:

-

Type: Steam Vulcanising Autoclave Machine

-

Condition: Refurbished & Fully Tested

-

Working Size: 1200 x 3600 mm

-

Usage: Rubber Sheet Curing & Vulcanising

-

Heating: Steam System for Even Curing

-

Performance: Industrial-Grade, Heavy-Duty Output

-

Efficiency: Safe, Consistent Pressure & Temperature

-

Support: Installation, Maintenance & AMC Available

-

Location: Available Across India – Ready to Ship

Refurbished XKJ480 Rubber Refiner Mill – Dalian Baofeng

Key Specifications:

-

Model: XKJ480 Rubber Refiner Mill

-

Brand: Dalian Baofeng (China)

-

Type: Reconditioned / Refurbished

-

Condition: Excellent, with warranty available

-

Application: Rubber refining, recycling, sheet processing

-

Roll Size: 480 mm

-

Power: Heavy-duty motor (customized as per buyer needs)

-

Usage: Suitable for tire recycling plants, rubber compounding, and sheet refining

Secondhand Old Rubber Refiner with Bushes & 100HP Gearbox

| Working diameter of rolls(mm) | φ400front roller φ480rear roller | φ450front roller φ510rear roller | φ480front roller φ610rear roller |

| Roll casting process | centrifugal composite casting | centrifugal composite casting | centrifugal composite casting |

| Roll cooling mode | Around the borehole cooling | Around the borehole cooling | Around the borehole cooling |

| The surface of the roll material | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy |

| Working length of the roll(mm) | 650 | 800/1000 | 800/1000/1200 |

| After the roller line speed(m/min) | 32.94(optional) | 49/55.2/63.4(optional) | 57.5-75.1(optional) |

| Front and rear roller line speed ratio | 1.27-1.815(optional) | 1.38/1.82/2(optional) | 1.27-1.815(optional) |

| Production capacity(kg/h) | 300 | 360 | 500-800 |

| Motor power(kw) | 55 | 55 | 75/90 |

| Roller spacing adjustment range(mm) | 0.1-15 | 0.1-15 | 0.1-15 |

| Reducer | ZSY hard-tooth face gear | ZSY hard-tooth face gear | ZSY hard-tooth face gear |

| Bearing type | the double spherical roller bearing | the double spherical roller bearing | the double spherical roller bearing |

| Dimensions of LxWxH(mm) | 4750x2300x1835 | 4060x2200x1470 | 5070x2800x1978 |

| Quality(kg) | about 10500 | about 12800 | about 20000 |

Unused Rubber Refiner Mill 480×610×800 | 2015 Make | 10 Ton

| Working diameter of rolls(mm) | φ400front roller φ480rear roller | φ450front roller φ510rear roller | φ480front roller φ610rear roller |

| Roll casting process | centrifugal composite casting | centrifugal composite casting | centrifugal composite casting |

| Roll cooling mode | Around the borehole cooling | Around the borehole cooling | Around the borehole cooling |

| The surface of the roll material | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy |

| Working length of the roll(mm) | 650 | 800/1000 | 800/1000/1200 |

| After the roller line speed(m/min) | 32.94(optional) | 49/55.2/63.4(optional) | 57.5-75.1(optional) |

| Front and rear roller line speed ratio | 1.27-1.815(optional) | 1.38/1.82/2(optional) | 1.27-1.815(optional) |

| Production capacity(kg/h) | 300 | 360 | 500-800 |

| Motor power(kw) | 55 | 55 | 75/90 |

| Roller spacing adjustment range(mm) | 0.1-15 | 0.1-15 | 0.1-15 |

| Reducer | ZSY hard-tooth face gear | ZSY hard-tooth face gear | ZSY hard-tooth face gear |

| Bearing type | the double spherical roller bearing | the double spherical roller bearing | the double spherical roller bearing |

| Dimensions of LxWxH(mm) | 4750x2300x1835 | 4060x2200x1470 | 5070x2800x1978 |

| Quality(kg) | about 10500 | about 12800 | about 20000 |

Used Rotocure Machine for Sale – Good Condition

Machine Details:

-

Type: Rubber Rotocure (Continuous Vulcanizing)

-

Condition: Used but well-maintained

-

Size: 900mm x 1400mm

-

Heating System: Fully functional

-

Rollers: Smooth operation, no defects

-

Application: Rubber sheet, conveyor belts, mats, flooring

-

Available with: Control panel, drive motor, and rollers

-

Power: 3 HP if known

Used XKJ 510 Rubber Refiner Mill – Buy Online

Key Specifications:

-

Machine Type: Twin Screw Rubber Sheeting Extruder (TSR)

-

Application: Rubber sheet production and processing

-

Screw Design: Twin screw with efficient sheeting output

-

Sheet Width Capacity: 560 – 760 mm (varies with model)

-

Motor Power: 75 – 110 KW (tested and reliable)

-

Condition: Used / Pre-owned (tested and verified)

-

Production Capacity: Medium to large-scale rubber industries

-

Warranty: Available on refurbished machines

-

Location: Available across India with delivery support

Compression Molding

Compression Molding