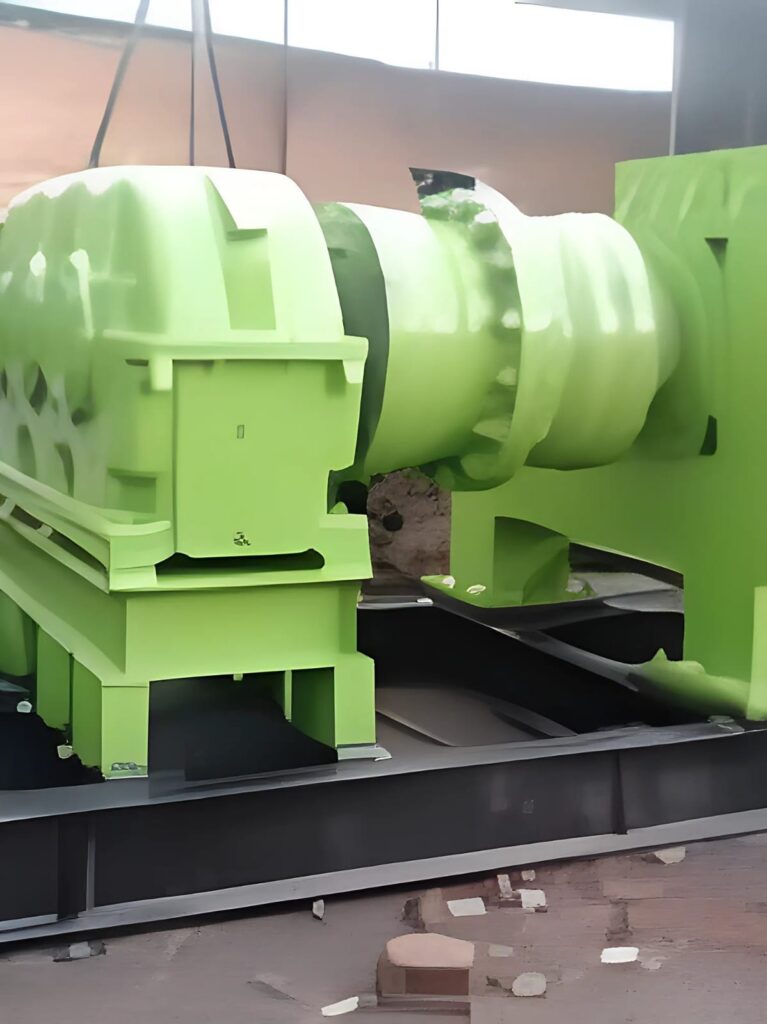

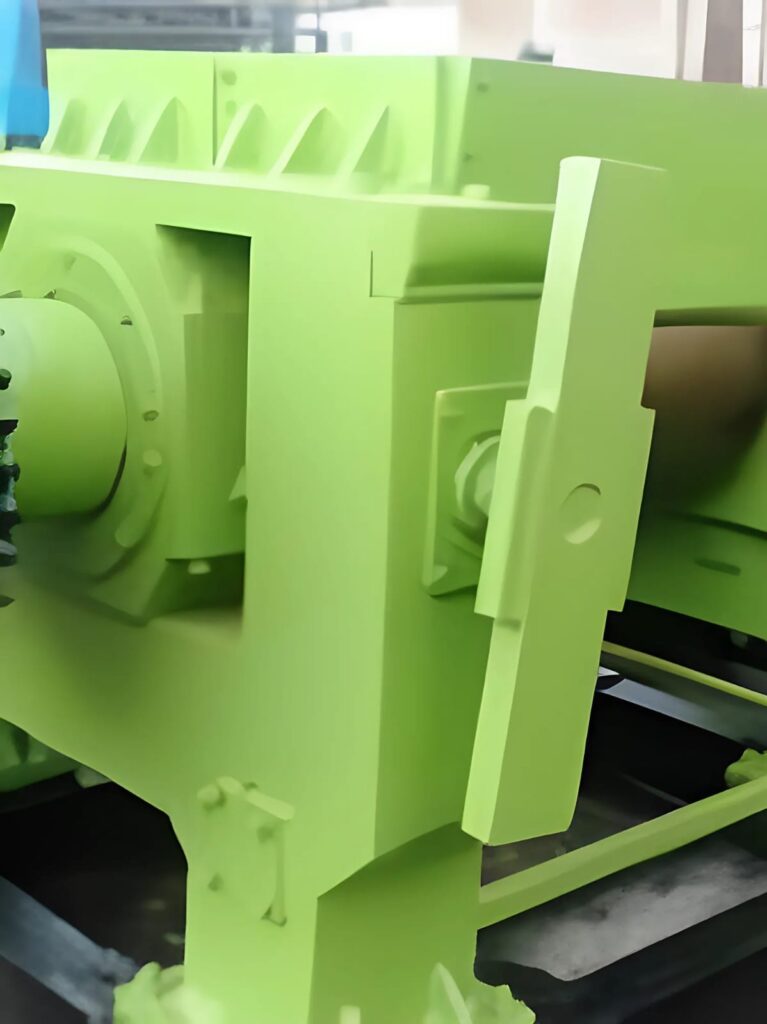

RUBBER RECLAIM MACHINERY

Want to update your rubber processing facility? Our second-hand Rubber Reclaim Machine provides consistent performance for economical processes. Vatsn Tecnic provides high-performance RUBBER RECLAIM MACHINERY throughout India, such as in Delhi, Mumbai, and Chennai. These pieces of equipment efficiently recycle scrap rubber into usable material, allowing companies to save raw costs. We exclusively provide only pre-owned systems, carefully vetted for robustness and delivery. Be it in rubber compounding or tire recycling, this machinery fits into your operations perfectly. Be part of thousands of businesses already enjoying the benefits of used Rubber Reclaim Machines under our servicing, maintenance, and business consultancy services.

Buy | Sell Used 480 X 510 X 800 mm Rubber Refiner Mixing Mill Reclaim Sheet Making Machine

Buy | Sell Used Rubber Refiner Mixing Mill 480 X 1200 mm

| SIZE(inch.) | OD (mm) | LENGTH (mm) | FRONT ROLL | REAR ROLL | CAPACITY (kg/hr) | OPERATION | DRIVE MOTOR (hp) | |

| VAT | 16"x12"x30" | 406.4/304.8 | 762 | 18 | 28 | 70-75 | Continuous | 40 |

| VAT | 18"x14"x36" | 487.2/355.6 | 914.4 | 17 | 24 | 110-140 | Continuous | 60/75 |

| VAT | 22"x18"x30" | 558.8/457.2 | 762 | 15 | 20 | 180-225 | Continuous | 110/125 |

| VAT | 24"x20"x36" | 609.6/533.4 | 914.4 | 13.5 | 19 | 250-350 | Continuous | 150 |

| VAT | 28"x24"x48" | 711.2/609.6 | 1219.2 | 11.5 | 16 | 375-500 | Continuous | 200/250 |

Buy | Sell Second hand Pre-Owned 480 X 610 X 1000 Refiner Mill For Rubber Reclaim

- Environmental Sustainability: The Pre-Owned Refiner Mill contributes significantly to environmental sustainability by enabling the recycling of rubber materials. By repurposing and refining old rubber, manufacturers can reduce their reliance on virgin rubber, leading to a decrease in waste and a smaller carbon footprint.

- High-Quality Reclaimed Rubber: The refiner mill ensures that the reclaimed rubber maintains high-quality standards. By precisely breaking down rubber compounds, the machine guarantees uniformity, strength, and elasticity in the resulting reclaimed material. This is crucial for industries that demand consistent performance in their rubber products.

- Cost-Effective Recycling: Opting for a pre-owned refiner mill from Vatsn Tecnic provides a cost-effective solution for businesses looking to enhance their rubber recycling capabilities. Vatsn Tecnic's expertise in refurbishing machinery ensures that the equipment functions at optimal levels, offering an economical alternative to new machinery purchases.

- Resource Efficiency: Reclaiming rubber through the refiner mill conserves valuable resources by extending the lifecycle of rubber materials. This sustainable approach aligns with global efforts to minimize waste and promotes circular economies within the rubber industry.

Buy | Sell Second hand Rubber Refiner Mill 18”X22”X30”

Buy | Sell Second hand Uni Drive Rubber Refiner Mill 21x24x36

Buy | Sell Secondhand Rubber Refiner Mill 450 X 510

| Type | VAT-400 | VAT-450 | VAT-480 |

| Working diameter of rolls(mm) | φ400front roller φ480rear roller | φ450front roller φ510rear roller | φ480front roller φ610rear roller |

| value="{"1":2,"2":"Roll casting process"}">Roll casting process | sheets-value="{"1":2,"2":"centrifugal composite casting"}">centrifugal composite casting | centrifugal composite casting | centrifugal composite casting |

| Roll cooling mode | Around the borehole cooling | Around the borehole cooling | Around the borehole cooling |

| The surface of the roll material | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy |

| Working length of the roll(mm) | 650 | 800/1000 | 800/1000/1200 |

| After the roller line speed(m/min) | 32.94(optional) | 49/55.2/63.4(optional) | 57.5-75.1(optional) |

| Front and rear roller line speed ratio | 1.27-1.815(optional) | 1.38/1.82/2(optional) | 1.27-1.815(optional) |

| Production capacity(kg/h)</td> | 360 | 500-800 | |

| Motor power(kw) | 55 | 55 | 75/90 |

| Roller spacing adjustment range(mm) | 0.1-15 | 0.1-15 | 0.1-15 |

| Reducer | ZSY hard-tooth face gear | ZSY hard-tooth face gear | ZSY hard-tooth face gear |

| Bearing type | the double spherical roller bearing | the double spherical roller bearing | the double spherical roller bearing |

| Dimensions of LxWxH(mm) | 4750x2300x1835 | 4060x2200x1470 | 5070x2800x1978 |

| Quality(kg) | about10500 | about12800 | about20000 |

Buy | Sell Secondhand Rubber Refiner Mill 450x510x1000 mm

| Working diameter of rolls(mm) | φ400front roller φ480rear roller | φ450front roller φ510rear roller | φ480front roller φ610rear roller |

| Roll casting process | centrifugal composite casting | centrifugal composite casting | centrifugal composite casting |

| Roll cooling mode | Around the borehole cooling | Around the borehole cooling | Around the borehole cooling |

| The surface of the roll material | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy |

| Working length of the roll(mm) | 650 | 800/1000 | 800/1000/1200 |

| After the roller line speed(m/min) | 32.94(optional) | 49/55.2/63.4(optional) | 57.5-75.1(optional) |

| Front and rear roller line speed ratio | 1.27-1.815(optional) | 1.38/1.82/2(optional) | 1.27-1.815(optional) |

| Production capacity(kg/h) | 300 | 360 | 500-800 |

| Motor power(kw) | 55 | 55 | 75/90 |

| Roller spacing adjustment range(mm) | 0.1-15 | 0.1-15 | 0.1-15 |

| Reducer | ZSY hard-tooth face gear | ZSY hard-tooth face gear | ZSY hard-tooth face gear |

| Bearing type | the double spherical roller bearing | the double spherical roller bearing | the double spherical roller bearing |

| Dimensions of LxWxH(mm) | 4750x2300x1835 | 4060x2200x1470 | 5070x2800x1978 |

| Quality(kg) | about 10500 | about 12800 | about 20000 |

Buy | Sell Secondhand Rubber Refiner Mill 480 X 610 X 1200 mm

| Type | VAT-400 | VAT-450 | VAT-480 |

| Working diameter of rolls(mm) | φ400front roller φ480rear roller | φ450front roller φ510rear roller | φ480front roller φ610rear roller |

| Roll casting process | centrifugal composite casting | centrifugal composite casting | centrifugal composite casting |

| Roll cooling mode | Around the borehole cooling | Around the borehole cooling | Around the borehole cooling |

| The surface of the roll material | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy |

| Working length of the roll(mm) | 650 | 800/1000 | 800/1000/1200 |

| After the roller line speed(m/min) | 32.94(optional) | 49/55.2/63.4(optional) | 57.5-75.1(optional) |

| Front and rear roller line speed ratio | 1.27-1.815(optional) | 1.38/1.82/2(optional) | 1.27-1.815(optional) |

| Production capacity(kg/h) | 300 | 360 | 500-800 |

| Motor power(kw) | 55 | 55 | 75/90 |

| Roller spacing adjustment range(mm) | 0.1-15 | 0.1-15 | 0.1-15 |

| Reducer | ZSY hard-tooth face gear | ZSY hard-tooth face gear | ZSY hard-tooth face gear |

| Bearing type | the double spherical roller bearing | the double spherical roller bearing | the double spherical roller bearing |

| Dimensions of LxWxH(mm) | 4750x2300x1835 | 4060x2200x1470 | 5070x2800x1978 |

| Quality(kg) | about10500 | about12800 | about20000 |

Buy | Sell Used Rubber Refiner Mill 450x510x1000 mm

| Working diameter of rolls(mm) | φ400front roller φ480rear roller | φ450front roller φ510rear roller | φ480front roller φ610rear roller |

| Roll casting process | centrifugal composite casting | centrifugal composite casting | centrifugal composite casting |

| Roll cooling mode | Around the borehole cooling | Around the borehole cooling | Around the borehole cooling |

| The surface of the roll material | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy | High nickel chromium molybdenum alloy |

| Working length of the roll(mm) | 650 | 800/1000 | 800/1000/1200 |

| After the roller line speed(m/min) | 32.94(optional) | 49/55.2/63.4(optional) | 57.5-75.1(optional) |

| Front and rear roller line speed ratio | 1.27-1.815(optional) | 1.38/1.82/2(optional) | 1.27-1.815(optional) |

| Production capacity(kg/h) | 300 | 360 | 500-800 |

| Motor power(kw) | 55 | 55 | 75/90 |

| Roller spacing adjustment range(mm) | 0.1-15 | 0.1-15 | 0.1-15 |

| Reducer | ZSY hard-tooth face gear | ZSY hard-tooth face gear | ZSY hard-tooth face gear |

| Bearing type | the double spherical roller bearing | the double spherical roller bearing | the double spherical roller bearing |

| Dimensions of LxWxH(mm) | 4750x2300x1835 | 4060x2200x1470 | 5070x2800x1978 |

| Quality(kg) | about 10500 | about 12800 | about 20000 |

Buy | Sell Used Rubber Refiner Mill Size 21 X 24 X 36

| SIZE(inch.) | OD (mm) | SIZE(inch) | FRONT ROLL | REAR ROLL | CAPACITY (kg/hr) | OPERATION | DRIVE MOTOR (hp) | |

| VAT | 16"x12"x30" | 406.4/304.8 | 762 | 18 | 28 | 70-75 | Contenuous | 40 |

| VAT | 18"x14"x36" | 487.2/355.6 | 914.4 | 17 | 24 | 110-140 | Contenuous | 60/75 |

| VAT | 22"x18"x30" | 558.8/457.2 | 762 | 15 | 20 | 180-225 | Contenuous | 110/125 |

| VAT | 24"x20"x36" | 609.6/533.4 | 914.4 | 13.5 | 19 | 250-350 | Contenuous | 150 |

| VAT | 28"x24"x48" | 711.2/609.6 | 1219.2 | 11.5 | 16 | 375-500 | Contenuous | 200/250 |

Buy | Sell Used Rubber Refiner Mill XKP 450 X 510 X 1000 mm

| SIZE(inch.) | OD (mm) | SIZE(inch) | FRONT ROLL | REAR ROLL | CAPACITY (kg/hr) | OPERATION | DRIVE MOTOR (hp) | |

| VAT | 16"x12"x30" | 406.4/304.8 | 762 | 18 | 28 | 70-75 | Contenuous | 40 |

| VAT | 18"x14"x36" | 487.2/355.6 | 914.4 | 17 | 24 | 110-140 | Contenuous | 60/75 |

| VAT | 22"x18"x30" | 558.8/457.2 | 762 | 15 | 20 | 180-225 | Contenuous | 110/125 |

| VAT | 24"x20"x36" | 609.6/533.4 | 914.4 | 13.5 | 19 | 250-350 | Contenuous | 150 |

| VAT | 28"x24"x48" | 711.2/609.6 | 1219.2 | 11.5 | 16 | 375-500 | Contenuous | 200/250 |

Compression Molding

Compression Molding