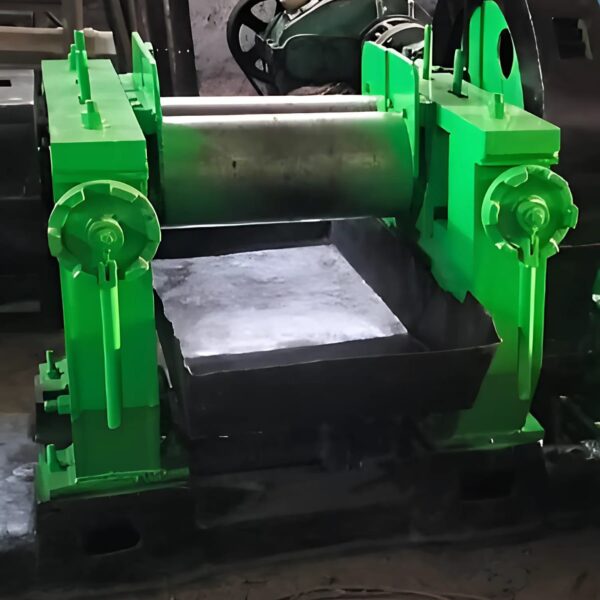

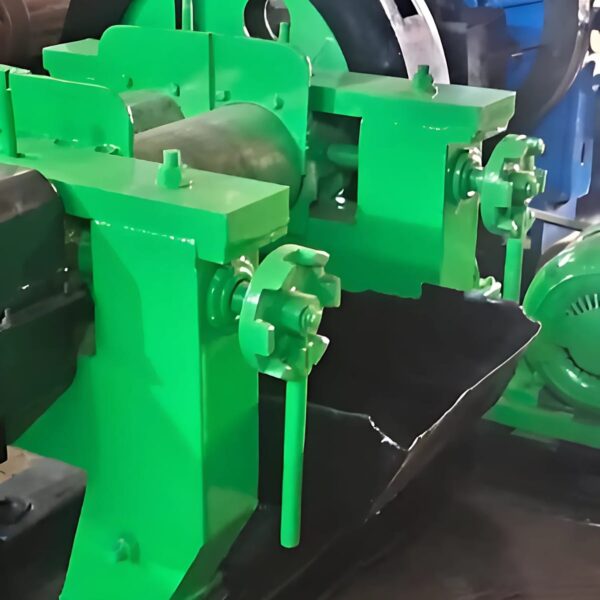

Meet the Secondhand Rubber Refiner Mill 480 X 610 X 1200 mm by Vatsn Tecnic. They are your trusted partner for all rubber processing needs. It does not matter whether you’re in Delhi, Mumbai, Chennai, or Bangalore. Vatsn Tecnic brings you top-quality machinery. They offer this in any major city in India and with unparalleled support services.

Product Description –

The Rubber Refiner Mill 480 X 610 X 1200 mm is a strong and efficient machine. Designers created it to refine and process rubber compounds. It has a small but strong build. It measures 480 X 610 X 1200 mm. This size makes it ideal for many industrial uses.

Uses of Rubber Refiner Mill –

1. Rubber Compounding: Achieve superior dispersion and mixing of rubber. This ensures optimal material properties.

2. Mixing: Mix different rubber ingredients well. Do this to make custom formulations for specific needs.

3. Devolatilization: Remove volatile components from rubber compounds, enhancing their stability and performance.

4. Refining: improves rubber quality and uniformity. This leads to better end products.

Why Choose Vatsn Tecnic –

i) Quality Assurance: Vatsn Tecnic does Quality Assurance. They ensure that each used Rubber Refiner Mill meets strict quality standards. This guarantees reliable performance and durability.

ii) Nationwide Reach: We have a presence in major cities across India. These include Delhi, Mumbai, Chennai, and Bangalore. This makes it convenient for customers to access our premium machinery and services.

iii) Comprehensive Support: Vatsn Tecnic offers more than sales. They also provide a range of support services. These include servicing, maintenance, and manpower provision. They also include annual maintenance contracts and consultancy for business expansion. You can trust our expertise. It will keep your operations running well.

iv) Cost-Effective Solutions: Vatsn Tecnic offers them by providing secondhand machinery. These solutions keep quality and help businesses optimize their investment.

Experience Excellence with Vatsn Tecnic –

Discover the reliability, efficiency, and low cost of the Secondhand Rubber Refiner Mill. It is 480 X 610 X 1200 mm and made by Vatsn Tecnic. Revolutionize your rubber processing operations and elevate your business to new heights. Contact us today to learn more and unlock the potential of your production line!

For more information Visit Here

Compression Molding

Compression Molding