Hot Feed Rubber Extruder Machine in Kerekla | Setup & Growth

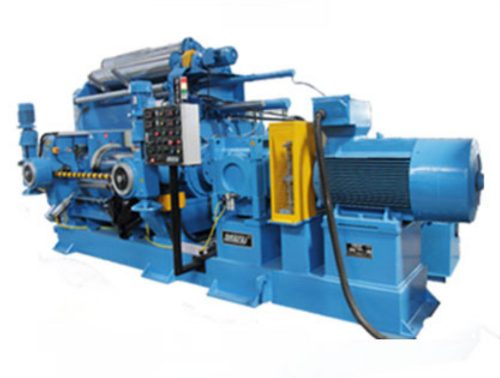

Hot Feed Rubber Extruder Machine in Kerekla: A Complete Guide for Manufacturers

Setting up a Hot Feed Rubber Extruder Machine in Kerekla is a smart move for entrepreneurs in the rubber processing and manufacturing sector. This blog explains key benefits, government support for machine makers, ideal industrial areas, and why vatsntecnic stands out as your top choice.

Why Install a Hot Feed Rubber Extruder Machine in Kerekla

Integrating a Hot Feed Rubber Extruder Machine in Kerekla can transform your production line. This high-temperature rubber extrusion unit helps improve quality, productivity, and competitiveness.

Boosted Production Output

A hot feed rubber extrusion system processes raw rubber continuously.

It improves throughput and reduces downtime. This means more finished product daily.

Consistent Rubber Quality

These machines provide uniform heat and pressure.

Your rubber products maintain consistent density and finish every batch.

Energy-Efficient Operations

Modern extruders use advanced heating systems that save electricity.

Lower power use reduces manufacturing costs.

Reduced Material Waste

Precise control of feed and temperature limits rubber scrap.

This boosts cost efficiency and minimizes raw material loss.

Scalable for Business Growth

The Hot Feed Rubber Extruder Machine in Kerekla can adapt to different production scales.

Start small and expand without heavy replacements.

These benefits make investing in this equipment worthwhile for rubber-based manufacturers.

Government Support Schemes for Rubber Machinery Makers in Delhi

5 Indian Government Programs For Rubber Dispersion Kneader Equipment Suppliers in Delhi

As a reputable supplier of rubber dispersion kneaders in New Delhi, you have access to numerous (5) Indian government programs designed to assist local suppliers of rubber machinery.

These (5) programs are;

- PMEGP (Prime Minister’s Employment Generation Programme): This program offers subsidized loans to help establish new or expand existing manufacturing facilities, including the purchase of rubber manufacturing equipment. MSME Story

- CLCSS (Credit Linked Capital Subsidy Scheme): This program provides capital subsidies to assist with technology upgrades and purchase of new machinery. (cvoca.org)

- CGTMSE (Credit Guarantee Fund Trust for Micro and Small Enterprises): This program provides MSE’s with an unsecured loan, which means they will not need to put up collateral to obtain a loan and an additional credit facility. Wikipedia

- Udyam Registration Benefits: Udyam registered MSE’s have access to government subsidies to help pay for utility bills and also have a streamlined process for applying for loans. Wikipedia +1

- Technology & Quality Improvement Program: The government provides financial assistance in the form of grants for purchasing advanced technology-based energy-efficient, high quality manufacturing machinery. (imtma.in)

Visitors who register as suppliers of rubber dispensing machines are able to use the benefits from these programs to access capital financing and technology to help their businesses grow and expand.

Best Industrial Zones for Hot Feed Rubber Extruder Machine Manufacturing in Kerekla

It is critical to select the most suitable location for setting up your hot feed rubber extruder manufacturing hub in Kerekla. Below is a list of possible industrial zones in Kerekla:

Kerekla Industrial Estate – has many factory sites that already have utilities installed.

Rubber Technology Park – provides an excellent environment for rubber machine manufacturers.

Industrial Growth Centre Zone – has good transportation options and offers governmental policy support to manufacturers.

Export-Oriented Manufacturing Park – provides a number of additional incentives and programs for selling goods overseas.

Special Economic Zone – provides a number of tax exemptions and export benefits.

Choosing to locate your facility in any of these areas can result in lower operating costs, enhanced logistical accessibility, and the creation of an overall skilled employee support system.

Step-by-Step Manufacturing of a Hot Feed Rubber Extruder Unit

Building a quality high-temperature rubber extrusion unit involves clear steps. Here are five core stages:

- Design & Engineering Planning

Draft technical schematics and choose components. - Raw Material Procurement

Buy high-grade steel, heaters, control systems, screws, and gears. - Fabrication & Assembly

Manufacture frame, barrel, and feeding system. Assemble controls. - Testing & Calibration

Run trials for temperature control, feed rate, and safety checks. - Packaging & Dispatch

Protect unit for transit and deliver to customer site.

Following these steps ensures precision, safety, and performance in each extruder.

Why Choose vatsntecnic for Rubber Extruder Needs?

When selecting a partner for your rubber processing machinery needs, look for a manufacturer that you can rely on. vatsntecnic offers several key factors to help you fulfill these requirements.

- Quality Machines – High-standard quality manufacturing of Hot Feed Rubber Extruder Machines in Kerekla.

- Technical Support – We provide technical support in the form of installation training and maintenance.

- Customized Solutions – Our machines are built for you based on your production volume and requirements.

- Affordable Prices – For the same price point our machines are both competitively priced and very high performing with excellent reliability.

- Proven Track Record – Many of our customers have come to us for their machinery needs because of our reputation for building durable equipment and delivering on time.

Final Thoughts on Hot Feed Rubber Extruder Machine in Kerekla

Investing in a Hot Feed Rubber Extruder Machine in Kerekla can increase your capacity to produce. Investing in hot feed rubber extruders will produce greater quantities of product at greater rates of manufacturing, as well as increasing the level of production quality and reducing the overall costs to the manufacturer. The combination of the government’s efforts to support the industry and the geographical location of the plant will allow for a successful rubber manufacturing venture. As for selecting a rubber machinery partner, vatsntecnic offers the best in quality, value and incredible reliability.

vatsntecnic

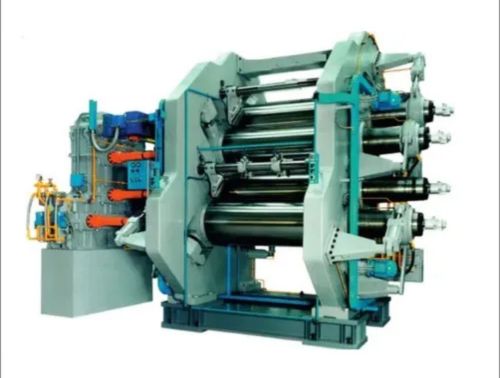

Compression Molding

Compression Molding