Calendering Process In Tire Manufacturing From Used Rubber Machine

The tire industry is always changing. It is adopting more sustainable practices. One big change is the use of rubber machines. Calendering uses them. Calendering is a key step in tire production. It helps form the tire’s tread and other vital parts. In this blog post, we’ll explore the calendering process in tire manufacturing. We’ll look at the benefits of using used calendering equipment. We’ll focus on the Vatsn technique.

1. Calendering Process in Tire Manufacturing –

Calendering is a mechanical process. It involves pressing rubber or other materials between rollers. This makes sheets or coatings of uniform thickness. In tire manufacturing, calendering is vital. It shapes and strengthens parts like the tire tread, inner liner, and sidewalls.

Here is a step-by-step overview of the calendering process in tire manufacturing:

i) Material Preparation:

- The primary material used in tire manufacturing is rubber, either natural or synthetic.

- We blend in extra additives, like carbon black and chemicals. They enhance the rubber’s properties.

ii) Batch Mixing:

The operator mixes the rubber compound in a batch mixer. They do this to make it have a uniform composition.

Mixing ensures the distribution of all additives. This helps the tire’s performance.

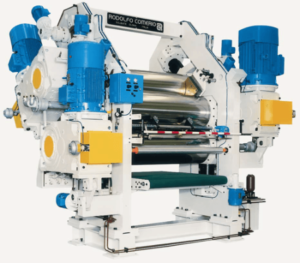

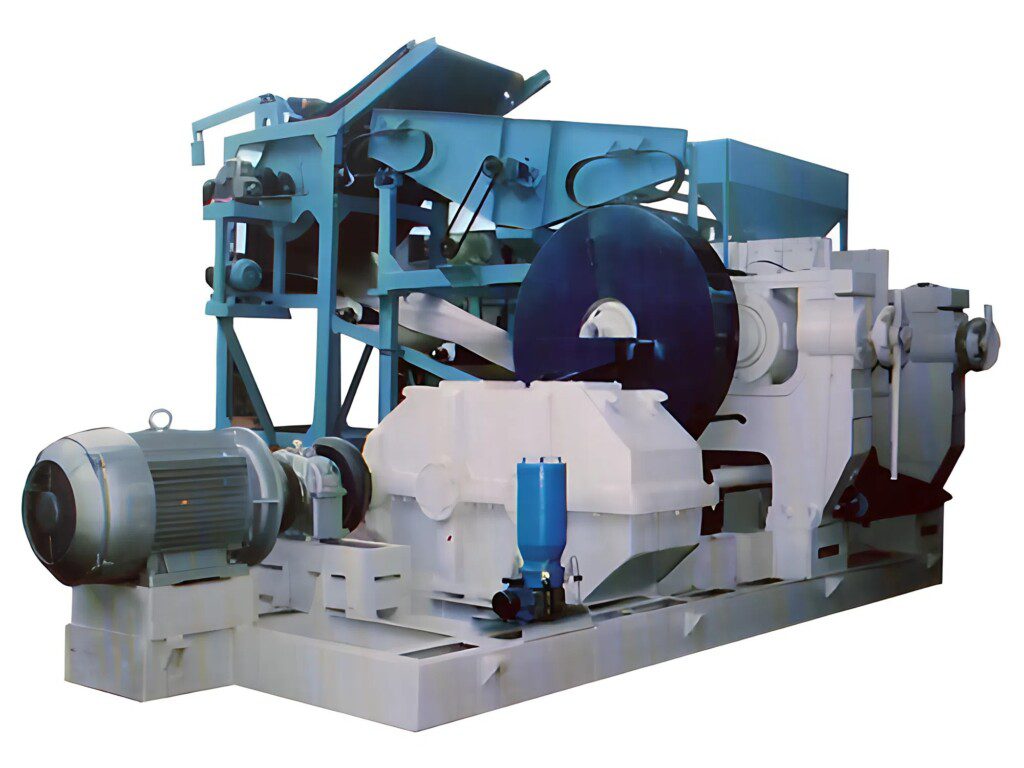

iii) Calendering:

- The mixed rubber compound is fed into the calendering machine, which consists of multiple rollers.

- These rollers compress and flatten the rubber into sheets of the desired thickness.

- We use the calendared sheets to create various components of the tire.

iv) Curing:

The sheets are then cured. They mold the rubber into the final tire shape.

During curing, manufacturers apply heat and pressure to achieve the desired tire properties.

Advantages of Using Secondhand Calendering Machines:

i) Cost Efficiency:

- Investing in used calendering machines significantly reduces the initial capital expenditure.

- Companies can allocate resources more efficiently, allowing for greater financial flexibility.

ii) Sustainability:

- Reusing existing machinery promotes sustainability by extending the lifespan of equipment.

- It reduces the environmental impact associated with manufacturing new machines.

iii) Technological Upgrades:

- Many secondhand machines can be upgraded with modern technology, enhancing their efficiency and performance.

- This allows manufacturers to stay competitive without investing in entirely new equipment.

2. The Vatsn Technique for Used Calendering Machines –

The Vatsn technique is becoming popular. It is effective for fixing and improving used calendering machines. This technique involves:

i) Thorough Inspection:

- Every component of the calendering machine is inspected to identify any wear and tear.

- Bearings, rollers, and other critical parts are examined to ensure proper functioning.

ii) Precision Refurbishment:

- Worn-out parts are replaced, and necessary repairs are made to restore the machine to optimal condition.

- While refurbishing, you can add digital control systems and other upgrades.

iii)Performance Testing:

The refurbished machine undergoes rigorous testing. This ensures it meets the required specifications.

We assess performance metrics to ensure reliability and efficiency.

Conclusion –

Tire manufacturing uses the calendering process. It uses used rubber machines, especially with the Vatsn technique. The process shows a sustainable and cost-effective approach. The industry is embracing practices. Using secondhand equipment reduces the environmental footprint. It also lets manufacturers achieve operational excellence.

For more information Visit Here

Compression Molding

Compression Molding