Buy Secondary Rasper Machine for Crumb Rubber in Maharashtra

Buy Secondary Rasper Machine for Crumb Rubber in Maharashtra

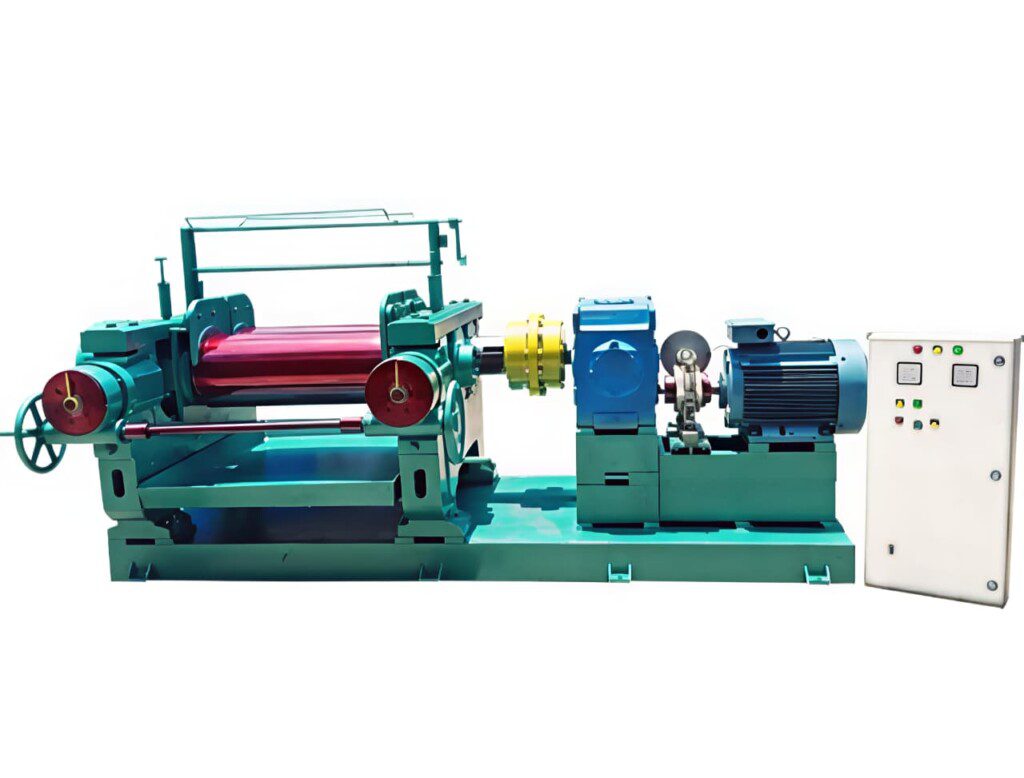

The rubber industry in Maharashtra is growing rapidly. Many businesses are now investing in secondary rasper machines for crumb rubber. These machines help convert old tires into high-quality crumb rubber. Setting up a rubber processing unit offers excellent business opportunities.

Advantages of Installing a Rubber Rasper Machine in Maharashtra

Investing in a rubber rasper machine for sale in Maharashtra has several benefits:

High efficiency: Processes large volumes of scrap tires quickly.

Cost savings: Reduces dependency on raw rubber material.

Quality output: Produces uniform crumb rubber suitable for various industries.

Eco-friendly: Converts waste tires into reusable products.

Profit potential: Crumb rubber can be sold to multiple sectors, including construction and manufacturing.

These machines are easy to operate and maintain. They ensure consistent output with minimal labor.

Understanding Rubber Shredding Machines

A rubber shredding machine is essential for tire recycling. It breaks down old tires into smaller pieces for further processing.

Primary shredder: Cuts tires into manageable chunks.

Secondary shredder: Reduces chunks into finer crumb rubber.

Tertiary shredder: Produces very fine rubber powder for specialized products.

Transitioning from shredding to grinding improves material quality. It also ensures the crumb rubber meets industry standards.

Types of Tire Shredders Commonly Used

There are three main types of tire shredder machines:

Single-shaft shredder: Ideal for medium to large tires; low maintenance required.

Double-shaft shredder: Handles larger volumes and heavier tires efficiently.

Granulator shredder: Produces uniform crumb rubber suitable for fine applications.

Choosing the right machine depends on your production needs and budget.

Government Support and Subsidies for Rubber Recycling

The Indian government supports rubber recycling businesses. Certain schemes and subsidies are available for entrepreneurs:

MSME benefits: Financial aid for small-scale rubber processing units.

Capital subsidies: Support for machinery purchase and installation.

Technology grants: Assistance for adopting eco-friendly recycling technology.

Tax exemptions: Certain incentives for environmentally sustainable businesses.

These schemes reduce investment costs and improve profitability. Entrepreneurs can check with local industrial offices for updated information.

Best Locations for Rubber Processing Units in Maharashtra

Selecting the right industrial zone is crucial for smooth operations:

Mumbai and Thane regions: Access to large markets and transport facilities.

Pune industrial belt: Ideal for manufacturing and logistics.

Nagpur: Central location for raw material supply and distribution.

Nashik: Suitable for small to medium-scale rubber processing units.

Proximity to tire scrap suppliers and end-product buyers improves efficiency. Proper location planning reduces logistics costs.

Why Buy or Sell Rubber Pulverizers with VatsnTecnic

VatsnTecnic is a trusted supplier of new and used rubber pulverizers:

Reliable machines: Fully tested and verified for smooth operation.

Wide variety: Offers secondary rasper machines, shredders, and granulators.

Competitive pricing: Affordable machines for all budgets.

After-sales support: Maintenance, spare parts, and technical guidance available.

Transparent deals: Clear documentation and trustworthy service.

Whether buying or selling, VatsnTecnic ensures a seamless experience.

Summary of Key Points

Investing in a secondary rasper machine increases efficiency and profits.

Rubber shredding machines are essential for converting tires into crumb rubber.

Three types of tire shredders include single-shaft, double-shaft, and granulator machines.

Government schemes provide subsidies, grants, and tax benefits.

Industrial zones in Maharashtra like Mumbai, Pune, Nagpur, and Nashik are ideal locations.

VatsnTecnic offers reliable solutions for buying and selling rubber pulverizers.

Starting a rubber recycling unit in Maharashtra is profitable and eco-friendly. Proper machinery, location, and government support improve chances of success.

FAQs

Q1: What is the capacity of a secondary rasper machine?

A: Capacities vary from 300 kg/hour to 1500 kg/hour depending on machine size.

Q2: Can crumb rubber be used in construction?

A: Yes, it is used for rubber flooring, asphalt, mats, and molded products.

Q3: Are government subsidies easy to apply for?

A: Yes, but you must meet MSME eligibility and environmental compliance criteria.

Q4: Does VatsnTecnic provide installation support?

A: Yes, they offer installation, maintenance, and technical training for all machines.

For More Information Visit Here

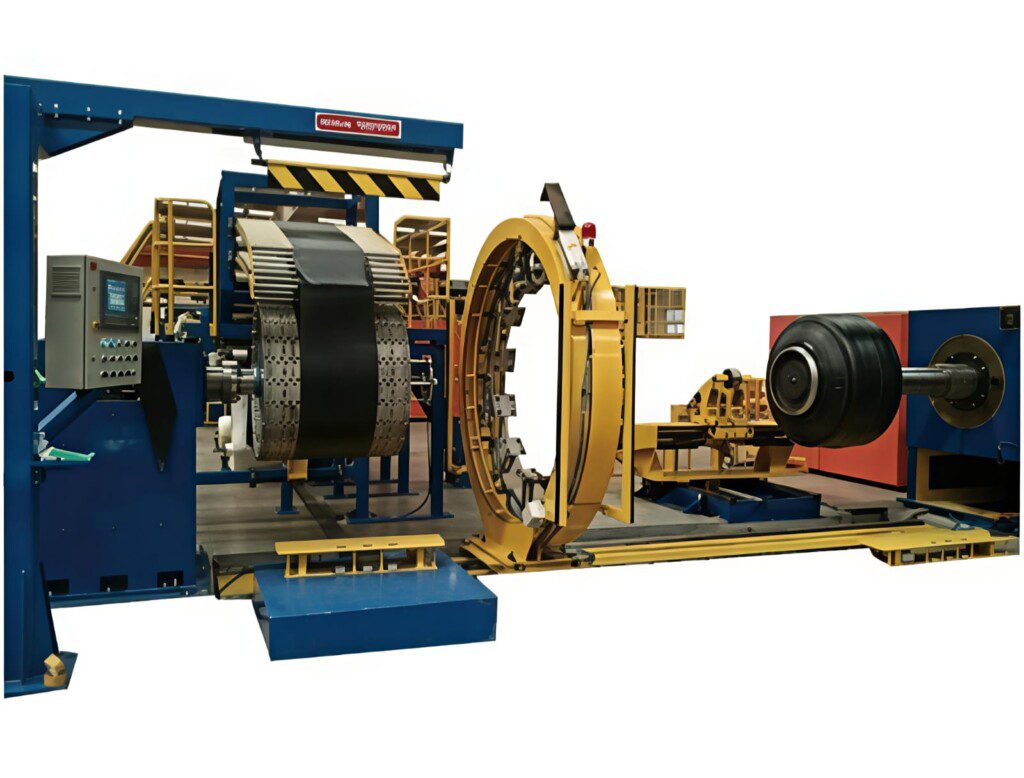

Compression Molding

Compression Molding