Rubber Mixing Mill For Sale | Buyer Guide

Rubber Mixing Mill for Sale | Buyer Guide Using Industrial System Production Line

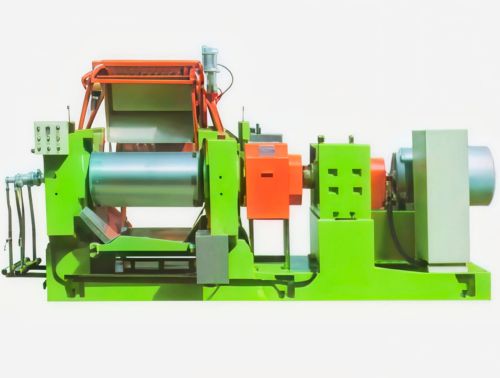

A Rubber Mixing Mill for sale supports reliable rubber compound preparation across multiple industries.

Moreover, buyers prioritize a stable production process for consistent batch quality.

Therefore, understanding industrial manufacturing steps helps buyers make informed investment decisions.

In addition, structured production system development improves long-term operational reliability.

As a result, equipment production units integrate smoothly within an industrial system production line.

A rubber mixing mill plays a critical role in compound uniformity.

Moreover, correct mill selection improves productivity and material performance.

Therefore, buyers must evaluate technical specifications carefully.

In addition, knowledge of the rubber mixing mill working principle supports smarter purchasing.

As a result, manufacturers achieve predictable results during daily operations.

Benefits of a Reliable Production Process in Maharashtra | Industrial Manufacturing Steps

A reliable production process improves compound consistency in rubber manufacturing.

Moreover, structured industrial manufacturing steps reduce formulation errors significantly.

Therefore, manufacturers experience fewer quality deviations during mixing cycles.

In addition, proper production system development supports stable throughput.

As a result, the machine making process delivers repeatable mixing performance.

Moreover, equipment production units consume optimized energy during operation.

Therefore, the industrial system production line maintains steady output levels.

Government Scheme for Setting Up a Trusted Supplier | Production System Development

Government initiatives support production system development for rubber machinery suppliers.

Moreover, industrial development support reduces financial pressure during setup phases.

Therefore, suppliers adopt modern machine making process technologies faster.

In addition, funding programs improve access to advanced equipment production units.

As a result, industrial manufacturing steps improve across regional supply chains.

Major Industrial Areas for Setting Up | Industrial System Production Line

Several Indian regions support industrial system production line expansion effectively.

Moreover, these zones provide skilled labor and strong logistics connectivity.

Therefore, manufacturers benefit from reduced operational delays.

In addition, regional clusters encourage faster production process scaling.

As a result, equipment production units operate efficiently in these locations.

How Industrial Systems Are Made | Step-by-Step Manufacturing Process Using Production Process

Industrial systems follow a structured production process to ensure reliable mixing performance.

Moreover, planning begins with production system development and capacity evaluation.

Therefore, engineers define industrial manufacturing steps based on compound behavior.

In addition, fabrication follows a standardized machine making process.

As a result, equipment production units achieve mechanical stability.

Moreover, testing confirms alignment with the industrial system production line.

Therefore, manufacturers receive dependable mixing performance after installation.

Why Choose VatsnTecnic? | Industrial Manufacturing Steps & Machine Making Process

VatsnTecnic delivers machines aligned with real industrial manufacturing steps.

Moreover, the company emphasizes a consistent production process design.

Therefore, buyers receive long-term production system development support.

In addition, experts explain the rubber mixing mill working principle clearly.

As a result, equipment production units perform reliably under demanding conditions.

Delhi Government Schemes | Equipment Production Units & Production Process

Moreover, capital subsidy schemes support production process investments

Therefore, interest reimbursement improves equipment production units affordability

In addition, technology upgradation enhances machine making process efficiency

As a result, industrial manufacturing steps remain competitive

Moreover, skill development programs strengthen industrial system production line operations

A Rubber Mixing Mill for sale requires careful technical and operational evaluation.

Moreover, buyers must understand the rubber mixing mill working principle thoroughly.

Therefore, correct roller size selection supports smooth industrial manufacturing steps.

In addition, proper production system development ensures long-term efficiency.

As a result, equipment production units deliver consistent compound quality.

The rubber mixing mill working principle depends on controlled shear and temperature balance.

Moreover, rollers rotate at different speeds during the production process.

Therefore, raw materials blend uniformly across industrial manufacturing steps.

In addition, accurate nip adjustment supports production system development goals.

As a result, the industrial system production line maintains compound stability.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For more information Visit Here

Compression Molding

Compression Molding