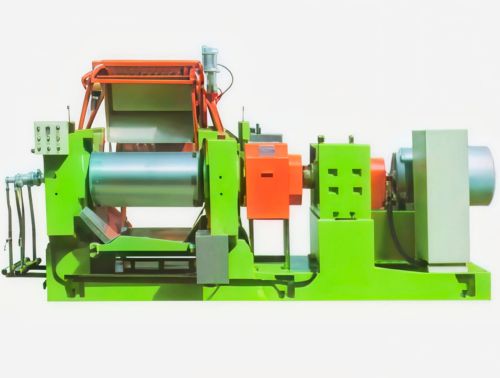

Crocs Slippers Machine provider Himachal Pradesh

Crocs Slippers Making Machine Service Provider in Himachal Pradesh

A reliable Crocs slippers making machine service provider in Himachal Pradesh supports modern footwear manufacturing growth.

Moreover, advanced machinery improves production accuracy and reduces material wastage.

Therefore, manufacturers demand efficient production process management and stable technical support.

In addition, regional service providers strengthen local equipment production units and employment.

As a result, Himachal Pradesh attracts footwear investors seeking long-term industrial success.

Furthermore, modern production system development ensures consistent slipper quality and scalable output.

Therefore, choosing an experienced service provider becomes a strategic manufacturing decision.

Moreover, machine performance directly influences industrial manufacturing steps and operational efficiency.

Benefits of a Reliable Production Process in Maharashtra | Industrial System Production Line

A reliable production process strengthens footwear operations across Maharashtra and nearby industrial markets.

Moreover, consistent machine performance stabilizes the industrial system production line.

Key Advantages:

Therefore, faster output improves overall production system development.

Moreover, reduced downtime strengthens equipment production units.

In addition, accurate molds support advanced machine making process results.

As a result, energy efficiency improves across industrial manufacturing steps.

Therefore, consistent quality enhances long-term brand reliability.

Moreover, scalable systems support industrial expansion goals.

Government Scheme for Setting Up a Trusted Supplier | Production System Development

Government schemes actively support footwear equipment production units across India.

Moreover, these programs strengthen industrial system production line growth.

Key Government Support Schemes:

Therefore, MSME subsidies reduce initial production process costs.

Moreover, capital investment schemes support machine making process expansion.

In addition, technology upgradation incentives encourage automation adoption.

As a result, infrastructure grants boost industrial manufacturing steps.

Therefore, skill development programs strengthen production system development.

Major Industrial Areas for Setting Up | Equipment Production Units

Industrial clusters provide essential infrastructure for footwear manufacturing growth.

Moreover, location selection directly impacts the industrial system production line.

Top Industrial Zones:

Therefore, Baddi supports strong equipment production units.

Moreover, Nalagarh offers excellent logistics connectivity.

In addition, Paonta Sahib attracts footwear manufacturing investors.

As a result, Solan promotes advanced production process setups.

Therefore, Una enables scalable machine making process facilities.

How Industrial Systems Are Made | Step-by-Step Manufacturing Process and Production Process

Industrial system production line development follows structured manufacturing stages.

Moreover, each step supports efficient production system development.

Step 1: Design Planning

Therefore, engineers finalize the machine making process layout.

Moreover, design planning ensures stable industrial manufacturing steps.

Step 2: Raw Material Selection

In addition, high-grade components strengthen equipment production units.

As a result, machine durability improves significantly.

Step 3: Component Fabrication

Therefore, precision fabrication supports the production process.

Moreover, accuracy enhances industrial system production line stability.

Step 4: Assembly Integration

In addition, skilled technicians assemble core systems.

As a result, production system development remains consistent.

Step 5: Testing and Calibration

Therefore, performance testing validates industrial manufacturing steps.

Moreover, calibration ensures reliable machine making process outcomes.

Step 6: Installation and Training

In addition, on-site setup supports equipment production units.

As a result, operators master the industrial system production line.

Why Choose VatsnTecnic? for Industrial Machine Manufacturing | Machine Making Process Excellence

VatsnTecnic delivers advanced industrial manufacturing solutions with proven expertise.

Moreover, the company supports every stage of production system development.

Key Advantages:

Therefore, reliable machines ensure consistent production process results.

Moreover, expert engineers guide industrial manufacturing steps precisely.

In addition, responsive technical support minimizes downtime.

As a result, clients achieve stable industrial system production line performance.

Therefore, long-term reliability strengthens equipment production units.

Delhi Government Scheme Support:

Moreover, startup incentives support machine making process investments.

Therefore, interest subsidies reduce financial pressure.

In addition, skill training programs enhance workforce readiness.

As a result, infrastructure assistance improves industrial manufacturing steps.

Therefore, policy support encourages sustainable production system development.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For more information Visit Here

Compression Molding

Compression Molding