Shop

Buy| Sell Used Rubber Rotocure Machine

Buy| Sell Used Rubber Rotocure Machine

Description:-

Heating Drum Diameter (mm):- 1200

Maximum Product Width (mm):- 1400

Maximum Product Thickness (mm):- 0.5-6

Drum Linear Speed (m/min):- 0.06-1.8

Steam Pressure (MPa):- ≤0.6

Vulcanizing Temperature ("C):- 140-160

Motor Power (kW):- 2.2

Dimension (LXWXH)(MM):- 2200*2800*2100

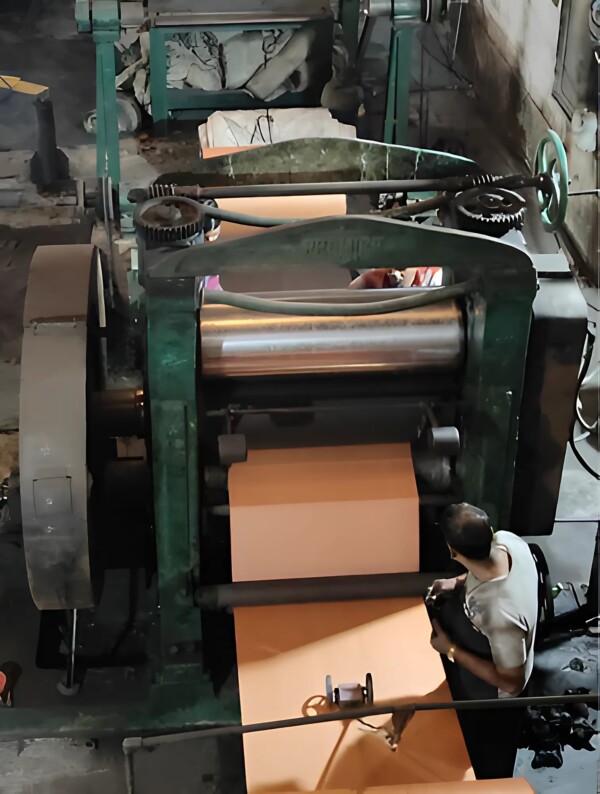

Buy| Sell Used Uni-Drive Rubber Mixing Mill Size of 16 X 42

<td>305307603096015-20

<td>13<tr>GMX-12”X30”12&amp;lt;/tr>

<td>mmInchmm</strong>HP</strong>RPMKg/H</strong>R</strong>

<p>369154096025-30<td>35-40

<td>100-150650</td>

84

</tr><td>GMX-14”X36”</tr>-16”X42”/td></tr>

<td>960<td>60<</td>

<tbody>strong>Model<strong>Chilled roll barrel dimensionDrive electric motor</strong></strong>Batch capacity</td><td>457/td><td>22

| < | ||||||||||||||||

| Diameter | Length | |||||||||||||||

| Inch | ||||||||||||||||

| GMX-6”X13” | 6 | 152 | 330 | 7.5 | 960 | 2-3 | ||||||||||

| GMX-8”X18” | 8 | 203 | 18 | 10 | 960 | 4-5 | ||||||||||

| <strong>GMX-10”X24”</td> | 10 | 254 | 24 | 610 | 20 | 960 | 6-9 | 14 | 355 | GMX | 16 | 406 | 42</td> | 1066 | 60 | 960 |

| GMX-18”X48”</strong></td> | 18 | 457 | 48 | 1220</td> | 75< | 40-50 | ||||||||||

| <strong>GMX-22”X60” | 560</td></td> | 1524 | 960 | 60-80 | <strong>GMX-26”X84” | 26 | 2134 | 200-250 | 960 | 90-105 | ||||||

| GMX-30”X100”</td> | 30 | 762</td> | 100 | 2540 | 300-350 | 960 | 125-200 | |||||||||

Buy|Sell Used Rubber Reclaim Plant Machinery

Introducing our state-of-the-art Rubber Reclaim Plant Machinery, designed to revolutionize the recycling process of rubber materials. Our cutting-edge machinery represents the pinnacle of innovation and efficiency in the reclaiming industry, offering a sustainable and cost-effective solution for recycling rubber.

Key Features:

- High-Quality Reclaiming: Our machinery is engineered to efficiently break down rubber materials, reclaiming and refining them into high-quality, reusable compounds. This process ensures minimal waste and maximum utilization of rubber resources.

- Advanced Technology: Equipped with the latest technological advancements, our reclaim plant machinery boasts precision in processing, ensuring consistency in output quality. Its intelligent design minimizes energy consumption while maximizing output, making it environmentally friendly and cost-efficient.

- Customizable Configurations: Our machinery offers versatile configurations to cater to various types of rubber materials and processing needs. Whether dealing with tires, conveyor belts, or other rubber products, our reclaim plant machinery can be tailored to suit specific requirements.

- Robust and Durable Build: Built with robust materials and components, our machinery guarantees durability and longevity. It operates seamlessly under demanding conditions, delivering reliable performance for continuous and uninterrupted processing.

- User-Friendly Interface: Designed with user convenience in mind, the machinery features an intuitive interface that simplifies operation and maintenance. This user-friendly interface ensures ease of use for operators, reducing downtime and enhancing productivity.

- Environmental Sustainability: By efficiently reclaiming rubber materials, our machinery contributes significantly to environmental conservation by reducing waste and the need for new raw materials.

- Cost-Efficiency: Recycling rubber through our machinery reduces production costs associated with acquiring new materials, offering a cost-effective solution for businesses.

- Quality Output: The reclaim plant machinery guarantees consistent and high-quality output, meeting industry standards and ensuring reliable performance of recycled rubber compounds.

- Automotive industry: for recycled tire compounds

- Industrial applications: in manufacturing various rubber products

- Environmental initiatives: for sustainable resource utilization

Buy|Sell Used Automatic Rubber Sheeting Complete Line

Product Details:

Payment & Shipping Terms:

| Place of Origin: | CHINA |

|---|---|

| Brand Name: | HHS |

| Certification: | CE ISO |

| Model Number: | XJL115-250 |

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD:20000-80000 /SET |

| Packaging Details: | wood package /20-40 container |

| Delivery Time: | 20 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50 sets/month |

Buy|Sell Used Hydraulic Press Rubber Compression

Introducing our top-of-the-line Hydraulic Press Rubber Compression system, designed to meet the most demanding requirements of the rubber manufacturing industry. Built with precision engineering and cutting-edge technology, this hydraulic press offers unparalleled performance, efficiency, and reliability.

Crafted with robust materials and engineered for durability, our press ensures consistent and uniform compression of rubber materials, guaranteeing high-quality finished products. Whether you're molding rubber sheets, components for automotive or industrial applications, or specialized rubber parts, this hydraulic press delivers exceptional results every time.

Key Features:

- Precision Control: Our hydraulic press offers precise control over pressure, temperature, and compression cycles, allowing for accurate molding of rubber materials according to specific requirements.

- Versatility: Versatility is at the core of this press. It accommodates various rubber materials, shapes, and sizes, providing flexibility in manufacturing different products.

- Efficiency: With its advanced hydraulic system, this press maximizes efficiency by minimizing cycle times, optimizing production output without compromising on quality.

- User-Friendly Interface: The user interface is designed for ease of operation, allowing operators to set parameters, monitor progress, and make adjustments effortlessly.

- Safety Measures: Safety is paramount. Our press is equipped with comprehensive safety features to ensure the well-being of operators and compliance with industry standards.

- Durability: Built to withstand rigorous operations, the press is constructed using high-quality materials, ensuring longevity and minimal maintenance requirements.

- Automotive Industry: Ideal for manufacturing rubber components for vehicles, including seals, gaskets, and O-rings.

- Industrial Applications: Perfect for creating custom rubber parts used in machinery, equipment, and specialized tools.

- Rubber Sheet Production: Efficiently produces uniform rubber sheets of varying thicknesses.

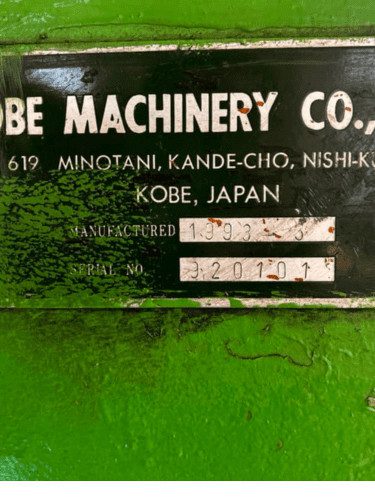

Double Compound Extruder 65-115 (Brand: Kobe):

| Model | VAT- 90 X 14D | VAT- 120 X 14D | VAT- 150 X 16D | VAT- 200 X 12D | VAT- 200 X 16D | VAT- 250 X 12D | VAT- 250 X 16D | |

| Screw diameter (mm) | 90 | 120 | 150 | 200 | 200 | 250 | 250 | |

| Screw L/ D ratio | 14/1 | 14/1 | 16/1 | 16/1 | 16/1 | 16/1 | 16/1 | |

| Max.Screw Speed (r/min) | 60 | 50 | 43 | 33 | 33 | 26 | 26 | |

| Feeding hole size (mm) | 120×80 | 160×110 | 200×165 | 260×152 | 260×152 | 340×190 | 340×190 | |

| Row quantity of pin | 8 | 10 | 10 | 8 | 12 | 10 | 12 | |

| Pin quantity of each row | 6 | 6 | 8 | 10 | 10 | 12 | 12 | |

| Motor model (kw) | Z4-180-41 | Z4-225-11 | Z4-250-11 | Z4-280-32 | Z4-315-12 | Z4-315-42 | Z4-355-12 | |

| Main motor Power (kw) | 55 | 110 | 220 | 315 | 355 | 400 | 450 | |

| Hot water circulation section | 3 | 3 | 4 | 4 | 4 | 4 | 4 | |

| Total power of hot water circulating heating (kw) | 32 | 32 | 42 | 42 | 54 | 48 | 54 | |

| Max.Production capacity (kg/h) | 360 | 800 | 1500 | 2600 | 2600 | 3600 | 3600 | |

|

Overall dimension(mm) |

(L) | 2300 | 3250 | 3800 | 5030 | 5900 | 5400 | 6077 |

| (W) | 1060 | 1250 | 1590 | 1950 | 1950 | 2400 | 2400 | |

| (H) | 1450 | 1650 | 1700 | 1850 | 1850 | 1920 | 1920 | |

| Weight (t) | 3.2 | 5.7 | 7.2 | 15 | 15 | 18 | 21 | |

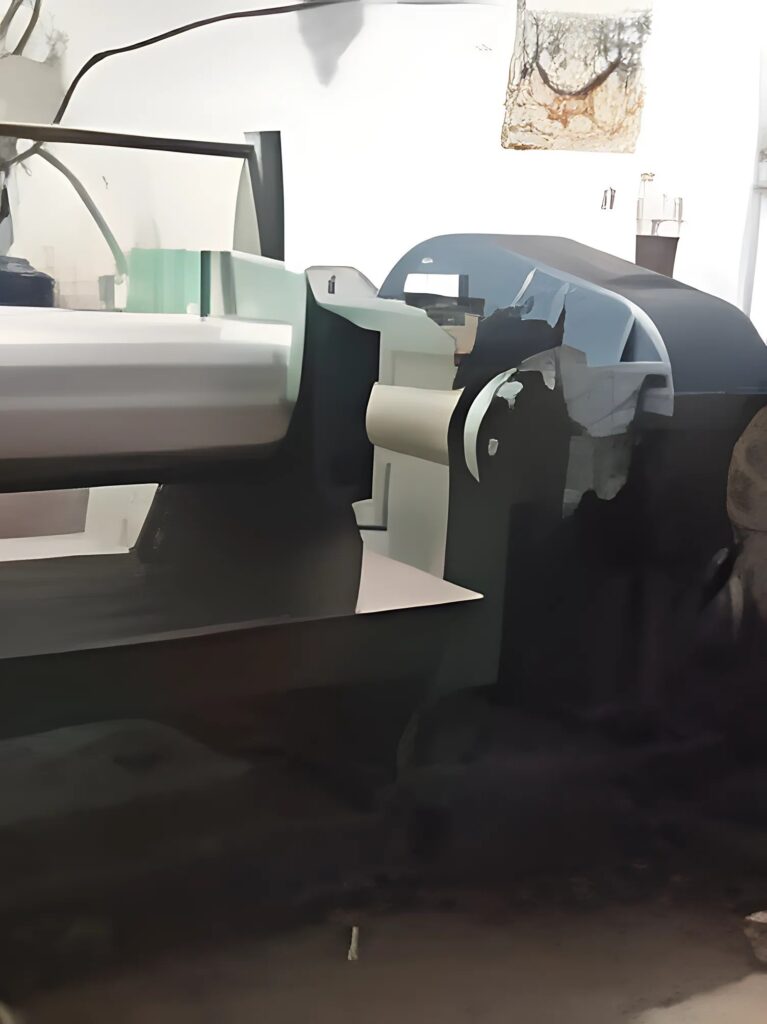

Ferrel Calender 3 Rolls (Size 18×54) for Rubber Sheeting

="0" cellpadding="0" data-sheets-root="1" data-sheets-baot="1"><td>1400&lt;/tr>

<td>Length5400

<td class="yoast-text-mark" colspan="2">wspan="1">Roll working length (mm)</td><td>720<td>132x3

| Parameter/model | VAT-3-250 | VAT-3-360 | VAT-3-400 | VAT-3-450 | VAT-3-560 | VAT-3-610 | VAT-3-810 | |

| Roll diameter (mm) | 250 | 360 | 400 | 450 | 560 | 610 | 810</td> | |

| 1120</td> | 1200 | 1650</td><td>1730 | 2130 | |||||

| Ratio of rubber speed | 1:1 | 1:1 | 1:1 | 1:1.5:1 | 1:1.5:1 | 1:1.4:1 | 1:01:01 | |

| Roll speed (m/min) | 2-15.9 | 3-20 | 3-26 | 2.6-26.2 | 3-30 | 5.4-54 | 3-30 | |

| Nip adjust range (mm) | 0-6 | 0-10 | 0-10 | 0-10 | 0-15 | 0.5-25 | 0.2-25 | |

| Motor power (KW) | 22 | 45 | 55 | 75</td> | 110 | 160 | ||

| Size (mm) | 3950 | 5600 | 7013 | 7200 | 7987 | 8690 | ||

| Width | 1110 | 1542 | 1400 | 1595 | 1760 | 1860 | 3139 | |

| Height | 1810 | 2440 | 2520 | 2900 | 3800 | 3950 | 5050 | |

| Weight (KG) | 5500 | 14000 | 18000 | 21000 | 35000 | 42000 | 110000 | |

Kobe 65/115 Twin-Screw Cold Feed Extruder for Motorcycle Tire

| Model | VAT- 90 X 14D | VAT- 120 X 14D | VAT- 150 X 16D | VAT- 200 X 12D | VAT- 200 X 16D | VAT- 250 X 12D | VAT- 250 X 16D | |

| Screw diameter (mm) | 90 | 120 | 150 | 200 | 200 | 250 | 250 | |

| Screw L/ D ratio | 14/1 | 14/1 | 16/1 | 16/1 | 16/1 | 16/1 | 16/1 | |

| Max.Screw Speed (r/min) | 60 | 50 | 43 | 33 | 33 | 26 | 26 | |

| Feeding hole size (mm) | 120×80 | 160×110 | 200×165 | 260×152 | 260×152 | 340×190 | 340×190 | |

| Row quantity of pin | 8 | 10 | 10 | 8 | 12 | 10 | 12 | |

| Pin quantity of each row | 6 | 6 | 8 | 10 | 10 | 12 | 12 | |

| Motor model (kw) | Z4-180-41 | Z4-225-11 | Z4-250-11 | Z4-280-32 | Z4-315-12 | Z4-315-42 | Z4-355-12 | |

| Main motor Power (kw) | 55 | 110 | 220 | 315 | 355 | 400 | 450 | |

| Hot water circulation section | 3 | 3 | 4 | 4 | 4 | 4 | 4 | |

| Total power of hot water circulating heating (kw) | 32 | 32 | 42 | 42 | 54 | 48 | 54 | |

| Max.Production capacity (kg/h) | 360 | 800 | 1500 | 2600 | 2600 | 3600 | 3600 | |

|

Overall dimension(mm) |

(L) | 2300 | 3250 | 3800 | 5030 | 5900 | 5400 | 6077 |

| (W) | 1060 | 1250 | 1590 | 1950 | 1950 | 2400 | 2400 | |

| (H) | 1450 | 1650 | 1700 | 1850 | 1850 | 1920 | 1920 | |

| Weight (t) | 3.2 | 5.7 | 7.2 | 15 | 15 | 18 | 21 | |

Old 14×36 Heavy Rubber Mixing Mill | 40 HP Motor, Bearing Type

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

|

Overall dimension(mm) |

L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

Compression Molding

Compression Molding