Used Rubber Rotocure Machine Buying Guide

Used Rubber Rotocure Machine Buyer Tips from the Shop Floor

Anyone who has worked in rubber manufacturing knows one thing: machines don’t need to be new to perform well. They need to be right. This is especially true when it comes to buying a Secondhand Rubber Rotocure Machine. Many plants across the world run successfully on pre-owned rotocure systems that deliver stable output every single day.

Still, buying used machinery is not about luck. It is about knowing what to look for and what to avoid. These buyer tips are based on real industrial considerations, not textbook theory.

Why Buyers Choose a Secondhand Rubber Rotocure Machine

In practical terms, a used rubber rotocure machine allows manufacturers to scale production without locking large capital into new equipment. For growing units, this flexibility matters.

Another reason is time. New machines often come with long delivery schedules. Used machines, on the other hand, are usually available immediately. For plants facing urgent capacity expansion or replacement needs, that speed can make a real difference.

What matters most is that rotocure machines are built heavy. When maintained properly, they age slowly.

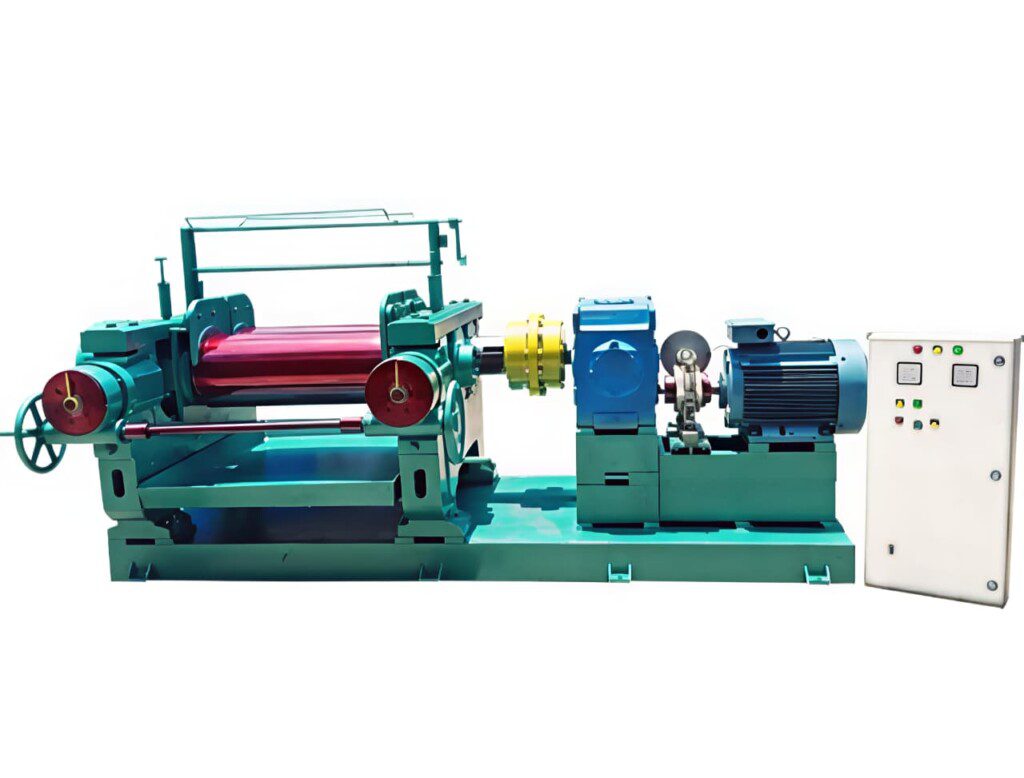

First Look at the Secondhand Rubber Rotocure Machine: What the Condition Really Tells You

When inspecting a used rubber rotocure machine, appearances can be misleading. Fresh paint does not mean good performance. Worn paint does not mean the machine is finished.

Focus instead on the core:

The steel belt should feel smooth, not patched or uneven

Drum rotation should be steady, without jerks or abnormal noise

Heating zones must respond evenly, not spike or lag

Drive systems should run clean, without vibration

If a test run is possible, take it seriously. Machines reveal their truth when they are working.

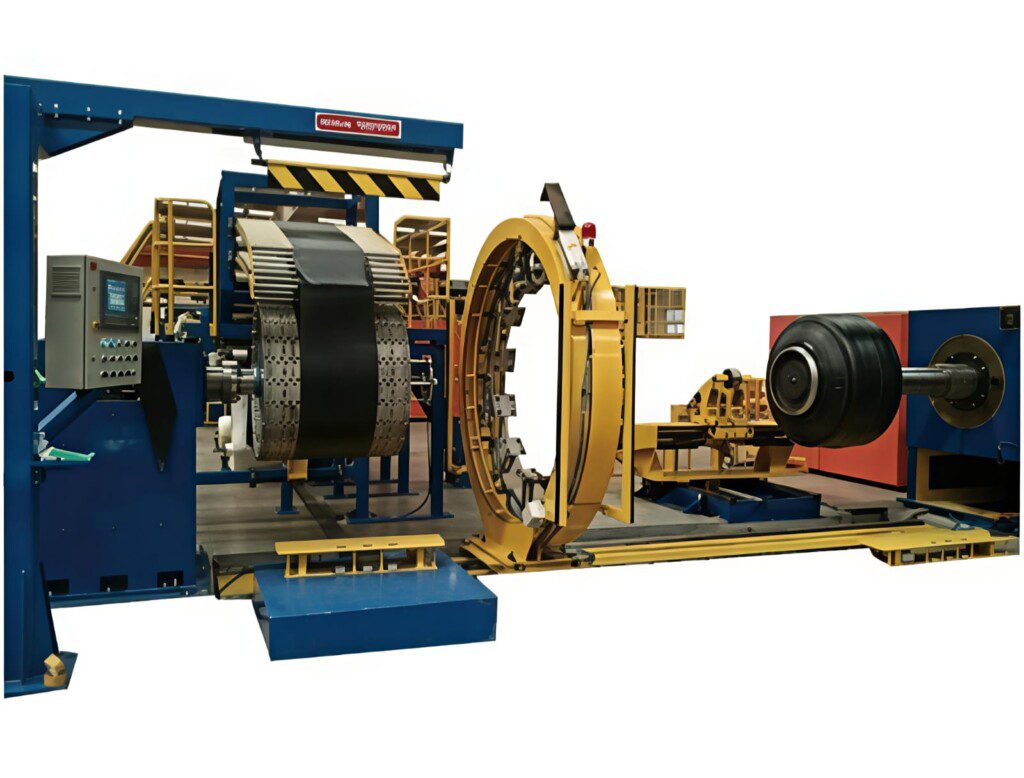

Specifications of Secondhand Rubber Rotocure Machine Matter More Than the Brand Name

Many buyers make the mistake of chasing brand labels instead of checking specifications. A used rubber rotocure machine must match your product, not your pride.

Before committing, confirm:

Effective curing width suits your product size

Operating temperature range meets compound requirements

Pressure control is stable, not manual guesswork

Power consumption aligns with plant capacity

A technically suitable machine will outperform a famous but mismatched one every time.

Maintenance History Is Not a Formality

Ask direct questions about maintenance. Not politely — clearly.

A Secondhand Rubber Rotocure Machine with a known service record is always safer than one with an unclear past. Bearings, heating elements, electrical wiring, and gearboxes tell a story. Good sellers know that story and can explain it.

Refurbishment is not a bad word. In fact, professionally refurbished machines often run better than neglected “original” ones.

Application History Should Match Your Needs

Not all rotocure machines live the same life. A used rubber rotocure machine that worked in conveyor belt production may have faced different stress compared to one used for rubber sheets or flooring.

Ask where it was used and how hard it was pushed. This helps predict future reliability and maintenance needs.

Applications commonly include:

Rubber sheets

Conveyor belts

Industrial mats

Coated fabrics

Technical rubber products

Alignment here reduces surprises later.

The Seller Is as Important as the Machine

One hard truth: problems usually come from bad sellers, not bad machines.

A reliable used rubber rotocure machine supplier will talk openly about limitations, not just strengths. They will guide you on installation, spares, and operation instead of disappearing after payment.

Long-term support matters, especially when dealing with heavy industrial systems.

Cost Is Not the Same as Value

Yes, used machines cost less. But the cheapest option is often the most expensive in the long run.

Think in terms of:

Remaining working life

Ease of maintenance

Spare part availability

Energy efficiency

Downtime risk

A slightly higher upfront cost often buys years of stable operation.

Installation Planning Is Often Ignored

Many buyers focus only on the machine and forget the environment. A used rubber rotocure machine needs proper foundation, power supply, space, and trained operators.

Poor installation creates problems that get wrongly blamed on the machine itself.

Plan before delivery, not after.

Closing Advice for Serious Buyers

A used rubber rotocure machine can be a strong asset when chosen with practical judgment. Look beyond surface condition, match specifications to your product, and work with suppliers who understand industrial realities.

Machines don’t fail randomly. Bad decisions cause failures. Careful evaluation prevents them.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For More Information Visit Here

Compression Molding

Compression Molding