Rubber Mixing Mill Retailer in Telangana | Complete Guide for Rubber Industry

Rubber Mixing Mills in Telangana – A Reliable Market for Industrial Growth

India’s rubber manufacturing sector is expanding rapidly. Moreover, Telangana is emerging as one of the strongest industrial regions in the country. With increasing demand from footwear, automotive, and engineering industries, manufacturers actively seek high-quality rubber mixing mills. Therefore, Rubber Mixing Mill retailers are gaining strong business momentum across the state.

In addition, local suppliers in Telangana support manufacturers by offering efficient machines, faster delivery, and dependable service. As a result, the state has become an ideal destination for businesses dealing in industrial rubber processing equipment.

Market Demand and Business Potential

The rubber industry plays a vital role in several sectors, including automotive parts, footwear production, and industrial components. Moreover, Telangana provides excellent infrastructure, which attracts new factories and processing units consistently.

Furthermore, small and medium enterprises prefer regional suppliers because they receive faster technical support and quicker delivery. Consequently, the market for rubber processing machinery continues to expand at a steady pace.

Advantages of Operating in Telangana

Setting up an industrial machinery supply business in Telangana offers many benefits. For example, businesses gain access to:

Strong road and rail connectivity

Reliable power supply for manufacturing units

Availability of trained technical workers

Competitive industrial land prices

Growing numbers of rubber processing factories

Therefore, these advantages create long-term stability and support continuous business growth.

Government Support for MSMEs

The Telangana government actively promotes industrial growth. As a result, it provides several incentives that help suppliers and manufacturers expand operations efficiently.

Key initiatives include:

TS-iPASS for fast project approvals

MSME capital investment subsidies

Power tariff support

Skill development programs

Interest subsidies on business loans

Consequently, these schemes reduce financial pressure and encourage sustainable industrial operations.

Major Industrial Zones

Telangana offers multiple well-developed industrial zones. Moreover, these locations provide strong logistics and customer access.

Important industrial areas include:

Hyderabad industrial clusters

Patancheru manufacturing hub

Jeedimetla machinery zone

Kukatpally industrial belt

Warangal industrial park

Therefore, these zones offer cost-effective setup options and long-term business advantages.

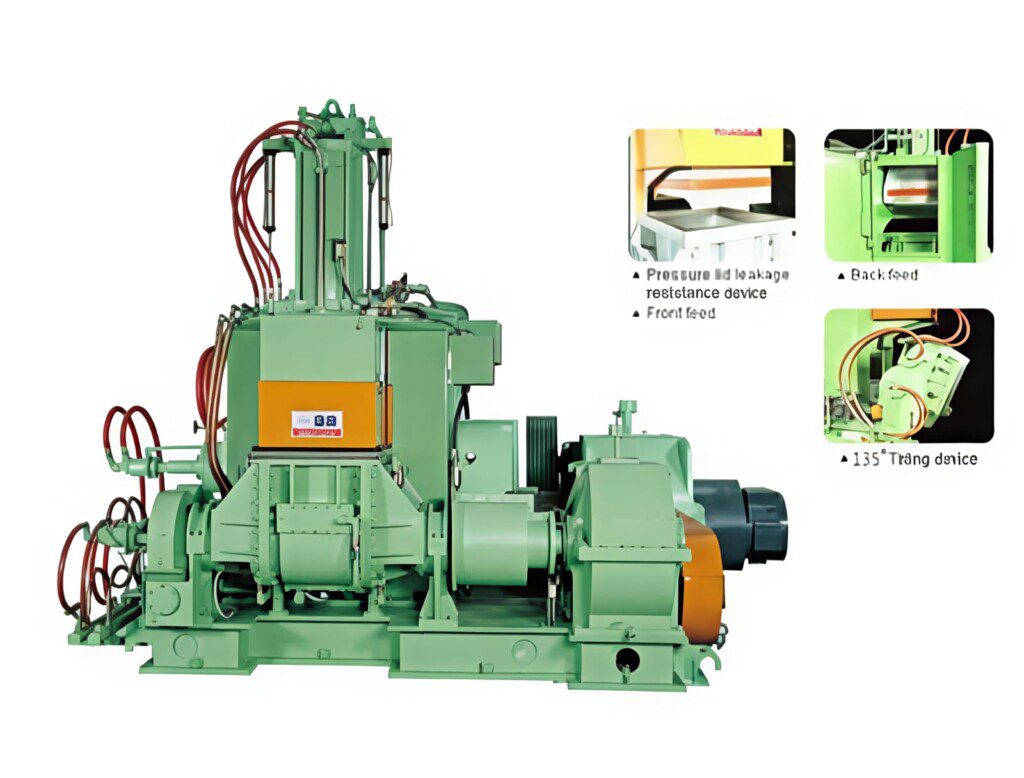

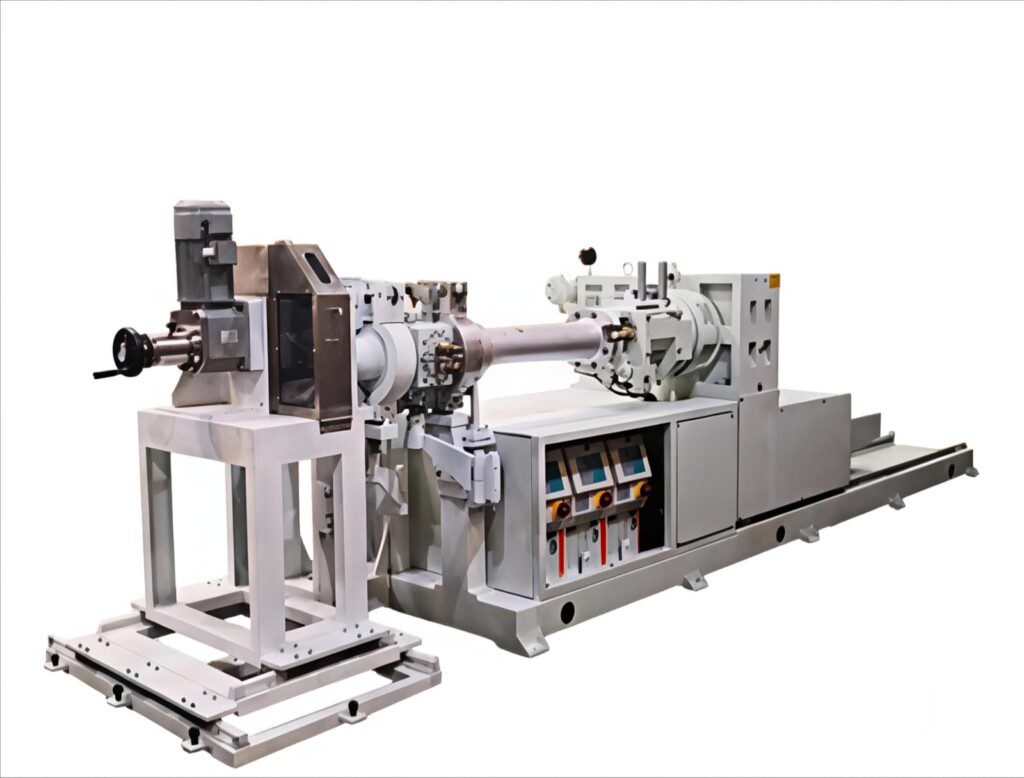

How Rubber Mixing Mills Are Manufactured

Understanding the manufacturing process builds customer trust. First, manufacturers select high-quality steel to ensure durability. Next, precision machining shapes rolls and frames accurately. Then, heat treatment improves strength and wear resistance.

After that, engineers assemble gearboxes and motors to ensure smooth power transmission. Finally, technicians test each machine for safety and performance before delivery. As a result, customers receive long-lasting and reliable equipment.

Industries That Use Rubber Mixing Mills

Rubber mixing mills serve a wide range of industries. For instance, these machines support:

Automotive rubber component production

Footwear and sole manufacturing

Conveyor belt plants

Rubber sheet and mat factories

Electrical insulation material production

Because of this, demand for rubber mixing mills remains strong and stable.

Why VatsnTecnic Is a Preferred Supplier

VatsnTecnic consistently delivers dependable industrial machinery for rubber and printing industries. Moreover, the company follows strict quality control systems and applies advanced engineering methods to ensure consistent mixing performance.

In addition, VatsnTecnic provides customization, installation support, and operator training. Therefore, businesses can start production faster and operate more efficiently.

How VatsnTecnic Builds Its Machines

VatsnTecnic follows a precise and controlled manufacturing workflow. First, teams inspect raw materials before production. Then, CNC machining ensures accurate dimensions. Meanwhile, assembly teams follow strict safety and performance standards.

After assembly, each rubber mixing mill undergoes load testing to confirm durability and long service life. As a result, customers receive reliable and high-performance machines.

Future Growth Outlook

The rubber sector in Telangana continues to grow steadily. Moreover, rising infrastructure development and manufacturing investments increase equipment demand. In addition, industries now prefer energy-efficient and automated machines.

Therefore, equipment suppliers have strong opportunities for expansion. With proper planning, businesses can achieve stable long-term growth.

Conclusion

Telangana offers a strong environment for rubber processing equipment businesses. Because of high demand, government support, and advanced industrial infrastructure, the state attracts both suppliers and manufacturers.

Ultimately, choosing a trusted machinery supplier improves operational success. VatsnTecnic delivers quality, reliability, and professional service for companies aiming to grow in the rubber manufacturing sector.

For more information Visit Here

Compression Molding

Compression Molding