Rubber Compression Molding in Sikkim

Rubber Compression Molding in Sikkim: A Complete Guide to Growth, Benefits, and Support

Rubber compression molding in Sikkim is expanding steadily across multiple industries.

Moreover, the state is emerging as a promising hub for rubber forming and industrial molding activities.

As a result, manufacturers now see new opportunities for production and investment growth.

In this guide, we explain the benefits, industrial zones, government support, and the role of VatsnTecnic.

Additionally, the content focuses on practical insights for entrepreneurs and decision-makers.

What Is Rubber Compression Molding in Sikkim?

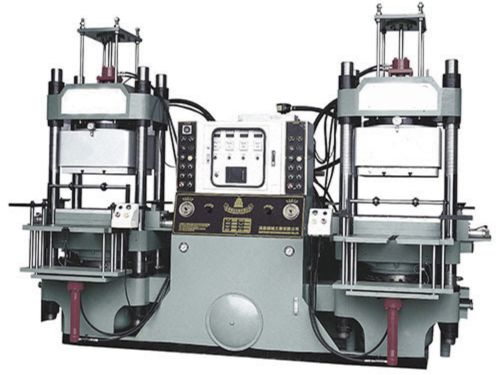

Rubber compression molding in Sikkim involves shaping rubber using controlled heat and pressure.

Through this method, manufacturers produce durable and high-quality rubber components.

Common products include gaskets, seals, automotive parts, and industrial mats.

Therefore, this process suits the needs of local manufacturing sectors.

In addition, small and medium enterprises benefit due to simple tooling requirements.

Top Benefits of Rubber Compression Molding in Sikkim

Rubber compression molding offers several operational advantages for manufacturers.

Moreover, these benefits support cost control and consistent output quality.

Cost-Effective Production

Because the process uses simple molds, overall production costs remain low.

High-Strength Components

As a result of uniform pressure, molded parts gain durability and strength.

Reduced Material Waste

Additionally, compression molding minimizes excess rubber usage.

Custom Shapes and Sizes

Therefore, manufacturers can easily handle customized product requirements.

Employment Generation

In turn, factories create jobs in both rural and urban regions.

Flexible Production Volumes

Furthermore, the process supports both small and large batch runs.

Environment-Friendly Options

Finally, recyclable rubber compounds help meet sustainability goals.

Government Schemes for Rubber Machine Units: Delhi Support

Starting a rubber machinery business requires funding and technical guidance.

Therefore, the Government of India offers multiple schemes for equipment suppliers in Delhi.

These programs help reduce setup costs and encourage modernization.

MSME Subsidies for Machinery Production

Under this scheme, manufacturers receive capital support for equipment investment.

Credit Linked Capital Subsidy Scheme

Moreover, businesses can obtain subsidies on approved machinery purchases.

Industrial Land at Preferential Rates

As a result, manufacturers gain access to affordable industrial plots.

Technology Upgradation Funds

Additionally, these funds help adopt advanced manufacturing tools.

Export Promotion and Duty Benefits

Finally, EPCG schemes reduce duties on imported machinery.

These initiatives simplify the establishment of reliable manufacturing units.

Major Industrial Zones for Rubber Compression Work in Sikkim

Although Sikkim is small, it offers suitable industrial locations for rubber processing.

Moreover, these zones support manufacturing, assembly, and logistics operations.

Rangpo Industrial Area

Because of its proximity to the Siliguri Corridor, logistics remain efficient.Rorathang Industrial Estate

This zone supports machinery and technology-based manufacturing.Singtam Industrial Zone

Additionally, it provides warehousing and transport facilities.Melli Industrial Cluster

As a growing hub, it supports small and medium enterprises.Singtam–Rangpo Belt

Finally, this area aids supply chains toward the Northeast.

Together, these zones encourage startup and SME development.

Rubber Molding Process: Key Steps Explained

Understanding the molding steps improves planning and quality control.

Therefore, manufacturers should follow each stage carefully.

Material Preparation

First, rubber compounds are mixed and cleaned.

Pre-Heating

Next, controlled heating improves material flow.

Mold Filling

Then, rubber enters the heated mold cavity.

Compression and Curing

After that, heat and pressure shape the product.

Unmolding

Finally, finished components are removed and trimmed.

Each step directly impacts consistency and durability.

Challenges in Rubber Compression Molding in Sikkim

Every industry faces operational challenges.

Similarly, rubber molding businesses encounter specific issues.

Limited skilled labor can slow production initially.

Meanwhile, raw material supply may face delays.

Additionally, rising energy costs affect operating margins.

In some cases, access to finance remains limited.

However, proper planning helps overcome competition from nearby states.

Why Rubber Molded Products Perform Better

Rubber molded components offer multiple performance advantages.

For example, they provide strength under pressure and flexibility.

Moreover, they absorb shock and resist heat and chemicals.

Because of these features, industries prefer rubber in demanding applications.

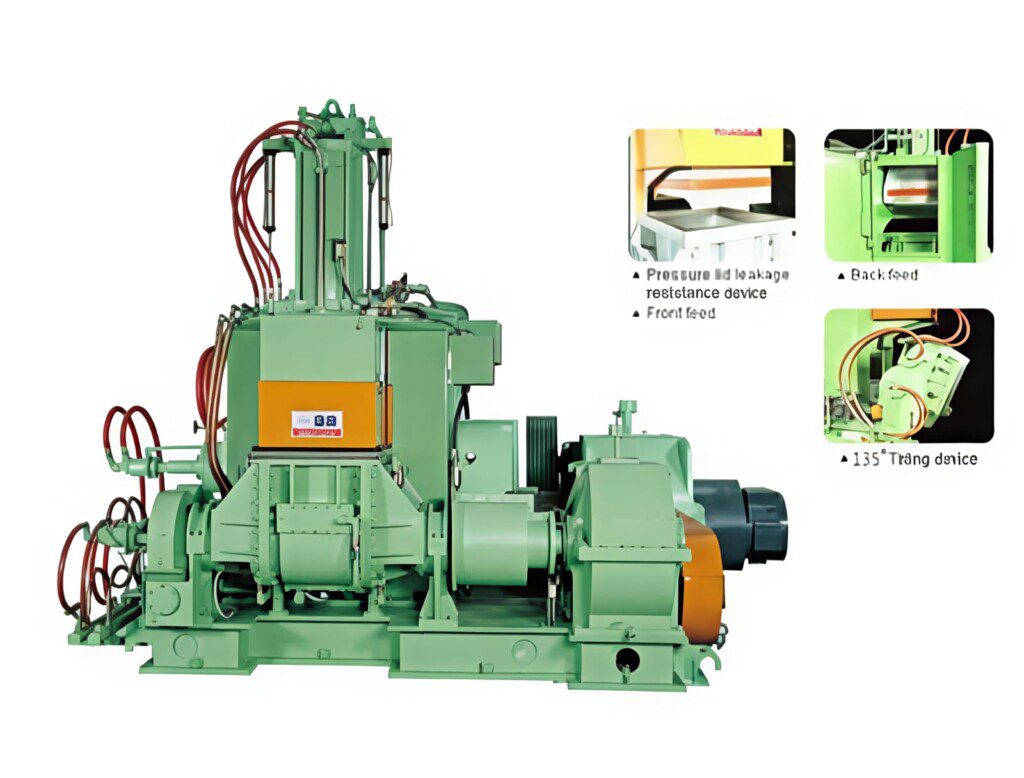

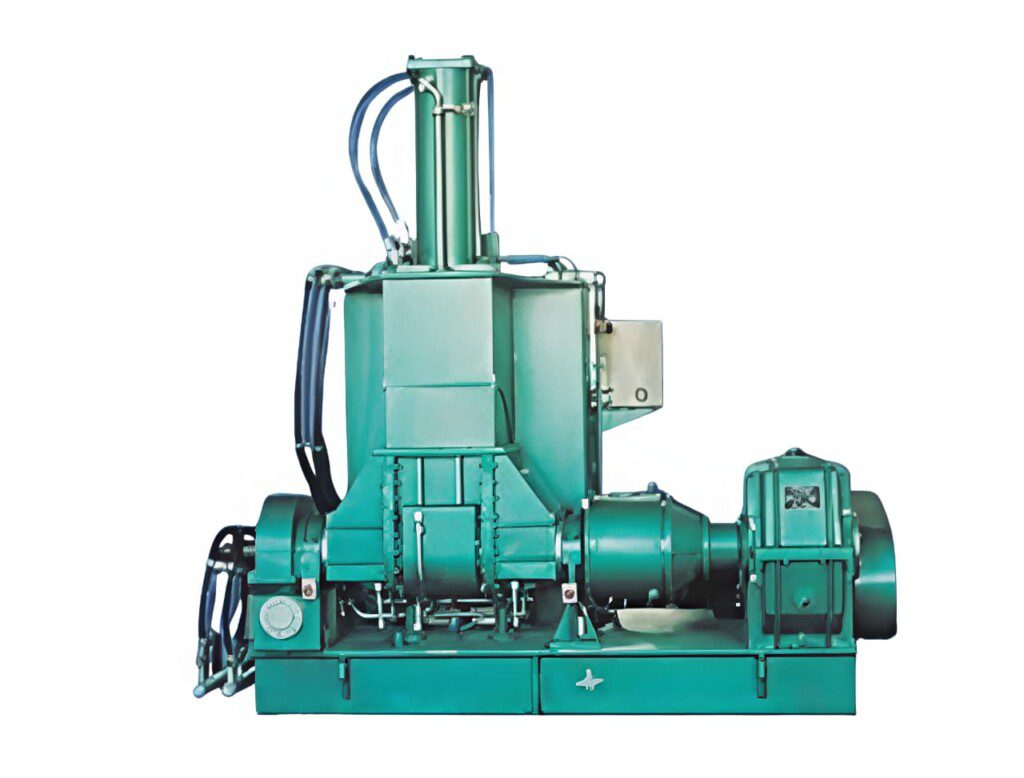

Importance of Reliable Rubber Dispersion Kneader Machines

Before molding, proper rubber mixing is essential.

Therefore, dispersion kneader machines play a vital role.

Stable mixing ensures uniform compound quality.

As a result, productivity increases while waste decreases.

Moreover, quality machines reduce breakdowns and maintenance needs.

In addition, spare parts support keeps downtime minimal.

Why Choose VatsnTecnic for Rubber Compression Needs

VatsnTecnic supplies dependable rubber processing machinery.

Moreover, their machines support stable production and long service life.

They serve both small workshops and large manufacturing units.

As a result, clients experience reduced downtime and improved output quality.

In addition, the support team assists during setup and expansion stages.

Key Reasons to Choose VatsnTecnic

Strong industry experience

Consistent machine quality

Reliable service network

Customized solutions

Cost-effective pricing

These strengths build long-term business confidence.

Practical Tips for New Rubber Molding Entrepreneurs

If you plan to start a rubber compression molding business, preparation matters.

First, study market demand carefully.

Next, select the right machinery and location.

Additionally, use government benefits to control costs.

With proper training and process control, product quality improves steadily.

Follow These Steps

Register under MSME

Choose logistics-friendly industrial zones

Invest in reliable molding and mixing machines

Use subsidies to reduce setup costs

Train workers on safety and quality

These actions increase success probability.

Conclusion: Grow Rubber Compression Molding in Sikkim

Sikkim offers strong potential for rubber compression molding growth.

Moreover, strategic location and government support attract entrepreneurs.

With correct planning and equipment investment, businesses can scale confidently.

Therefore, choosing reliable technology partners becomes essential.

Work with trusted suppliers and focus on quality-driven production.

VatsnTecnic supports long-term growth through dependable machinery and expert guidance.

Compression Molding

Compression Molding