Buy | Sell Used Rubber Compound Mixing Mill 26X60 Motor 180 Hp

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

|

Overall dimension(mm)

|

L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

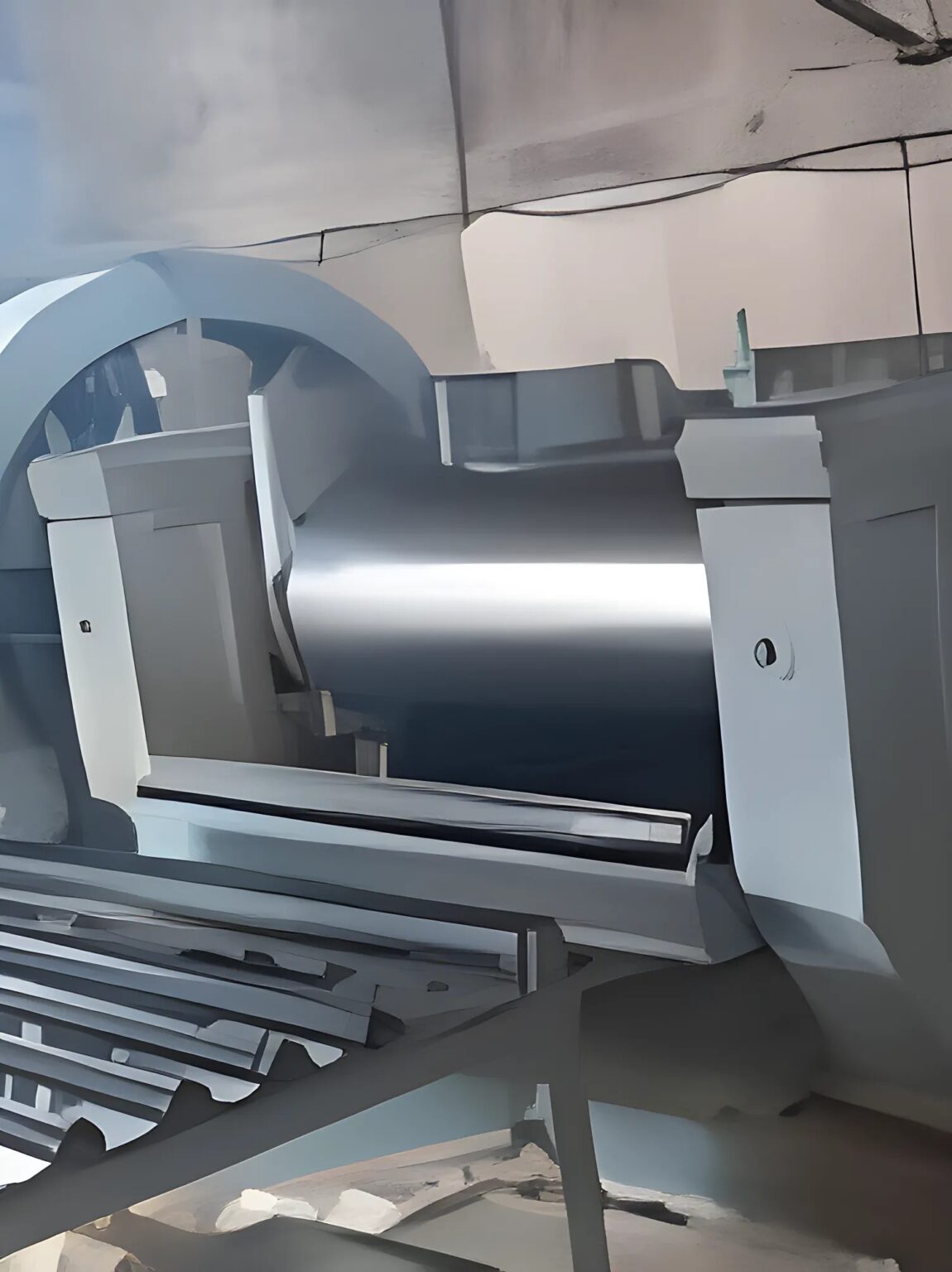

This is the Rubber Compound Mixing Mill 26X60. It is a tough industrial machine. The design makes the process of mixing rubber compounds fast and exact. This machine has a powerful 180 HP motor. Engineers designed it to meet the demands of heavy-duty industrial jobs.

Product Features –

1. Reliable Performance: With a sturdy build and powerful motor, this mixing mill ensures consistent and reliable performance, even under high workloads.

2. Efficient Mixing: Equipped with advanced mixing technology, it effectively blends rubber compounds to achieve desired properties such as elasticity, strength, and durability.

3. Large Capacity: The spacious 26X60-inch mixing chamber offers ample room for large batches of rubber compounds, allowing for increased productivity and reduced processing time.

4. Durable Construction: Crafted from high-quality materials, including durable steel components, this mixing mill is built to withstand the rigors of continuous operation in industrial environments.

5. User-Friendly Design: Featuring intuitive controls and easy-to-access components, it ensures convenient operation and minimal downtime for maintenance tasks.

Uses of Rubber Compound Mixing Mill –

i) Rubber Industry: It is great for rubber manufacturers. They make a wide range of products like tires, belts, hoses, and more.

ii) Automotive Sector: Essential for creating rubber compounds used in various automotive components, including seals, gaskets, and vibration dampeners.

iii) Construction Materials: Used for mixing rubber compounds utilized in construction materials like rubberized asphalt for roads and waterproof membranes.

iv) Industrial Applications: Finds applications in diverse industrial sectors requiring custom rubber compounds, including aerospace, marine, and electronics.

Why Choose Vatsn Tecnic?

1. Specialization in Secondhand Equipment: Vatsn Tecnic specializes in dealing with secondhand rubber compound mixing mills, offering cost-effective solutions without compromising on quality.

2. Nationwide Presence: With a strong presence in major cities across India such as Delhi, Mumbai, Chennai, Bangalore, and more, Vatsn Tecnic ensures prompt and reliable service to customers nationwide.

3. Comprehensive Services: Apart from equipment sales, Vatsn Tecnic provides a range of services including servicing, maintenance, manpower supply, annual maintenance contracts (AMC), and consultancy for business expansion, ensuring comprehensive support throughout the equipment lifecycle.

4. Expertise and Experience: With years of experience in the industry, Vatsn Tecnic boasts a team of skilled professionals who are dedicated to delivering superior products and services tailored to the specific needs of customers.

For more information Visit Here

Compression Molding

Compression Molding