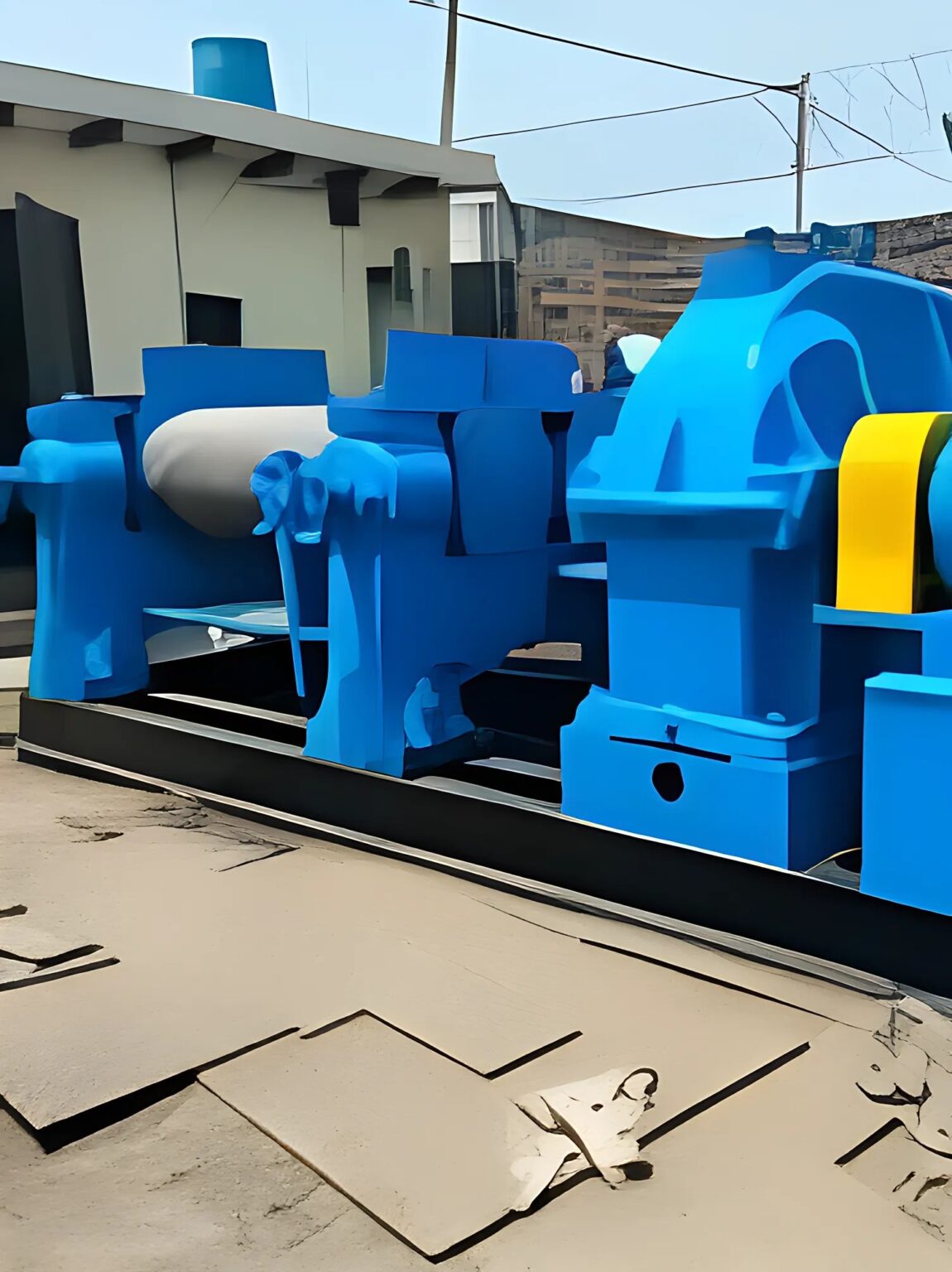

Buy | Sell Used Uni-drive Rubber Mixing Mill 22 X 60 Motor 100 Hp

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

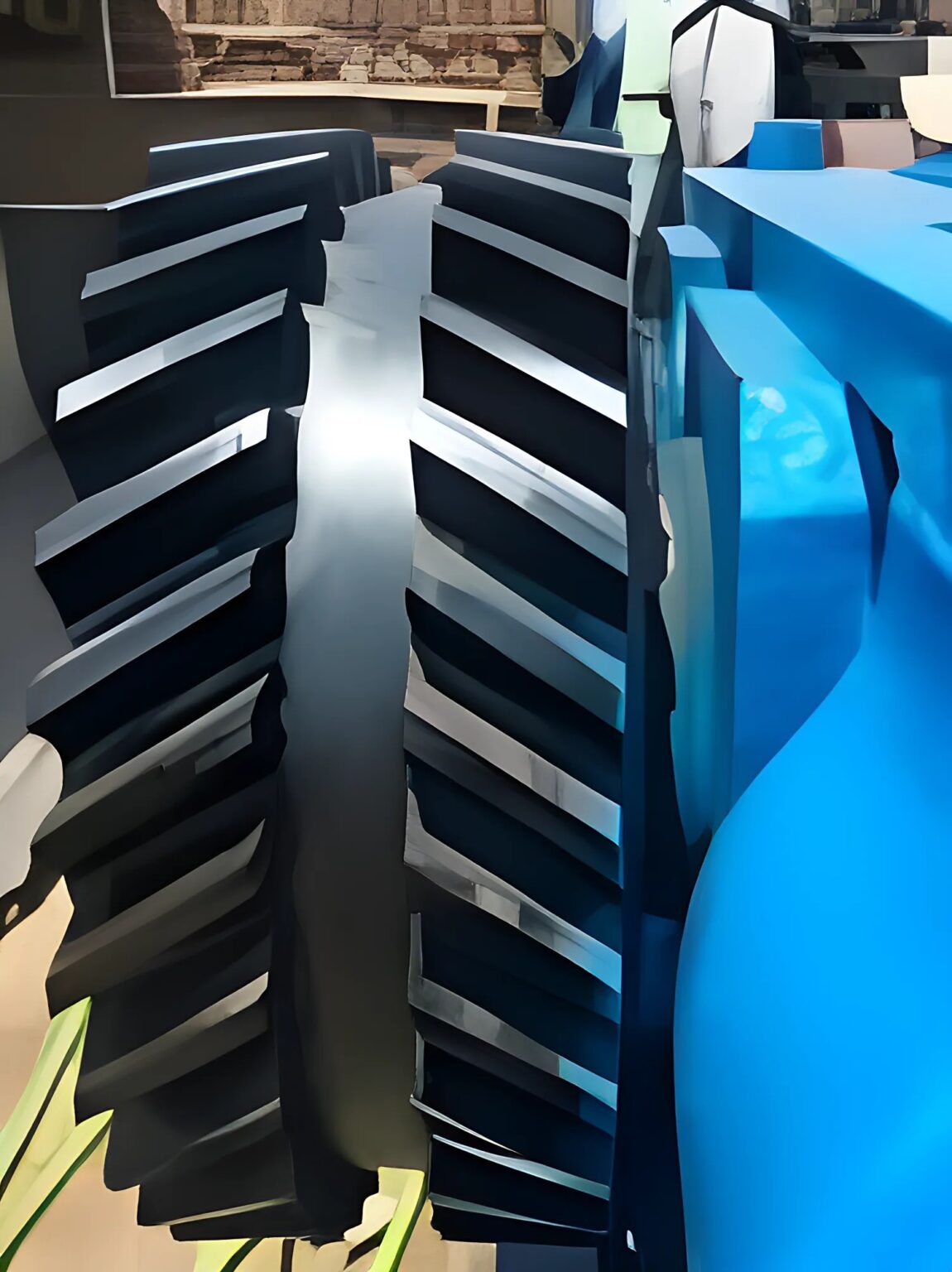

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

|

Overall dimension(mm)

|

L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

Introducing the Uni-drive Rubber Mixing Mill 22 X 60 Motor 100 HP – your trusted solution for precision rubber mixing in industrial settings. Whether you’re in the rubber manufacturing industry or require efficient rubber processing for your business, this Uni-drive Rubber Mixing Mill is your ultimate companion.

Product Features –

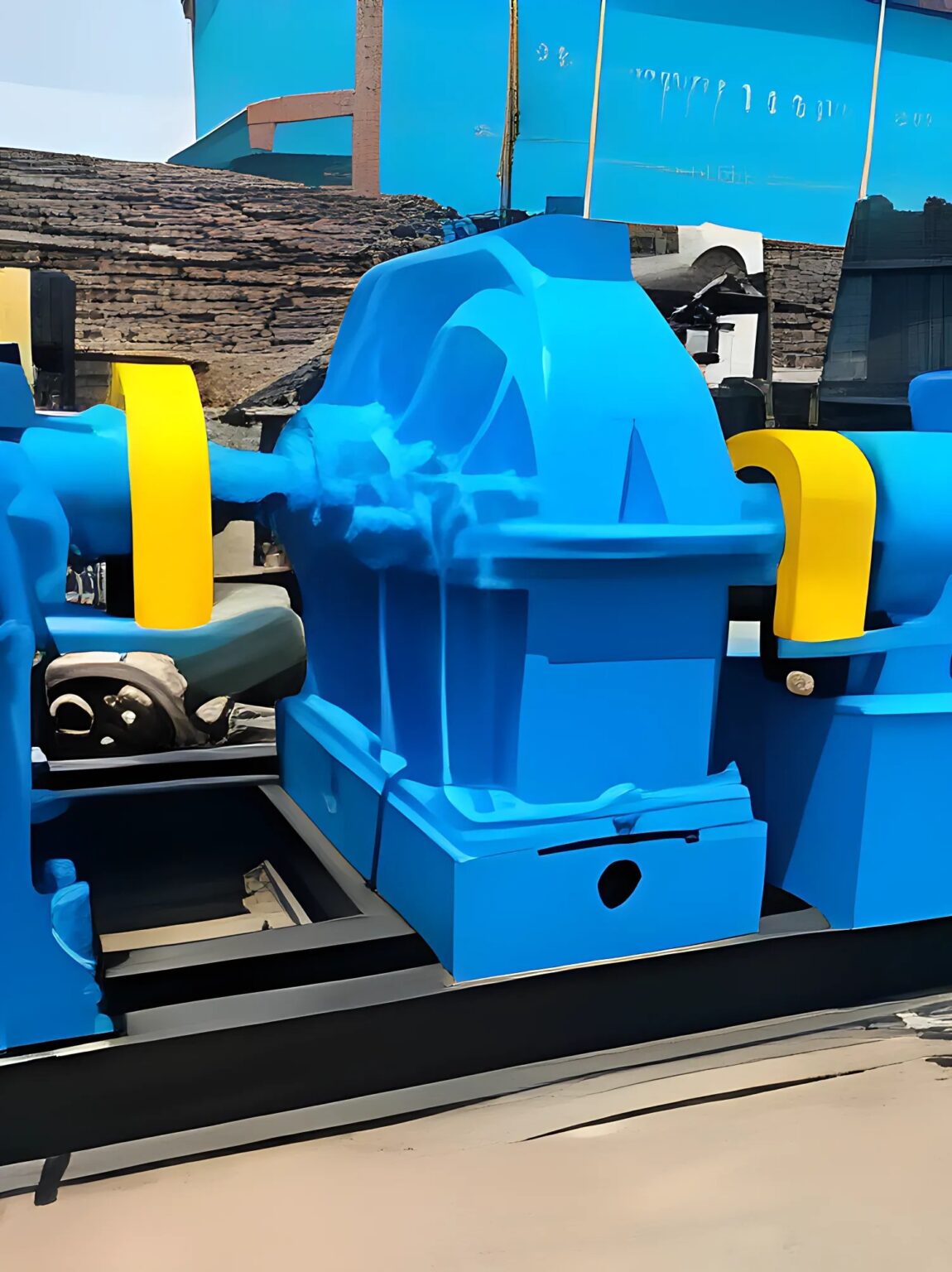

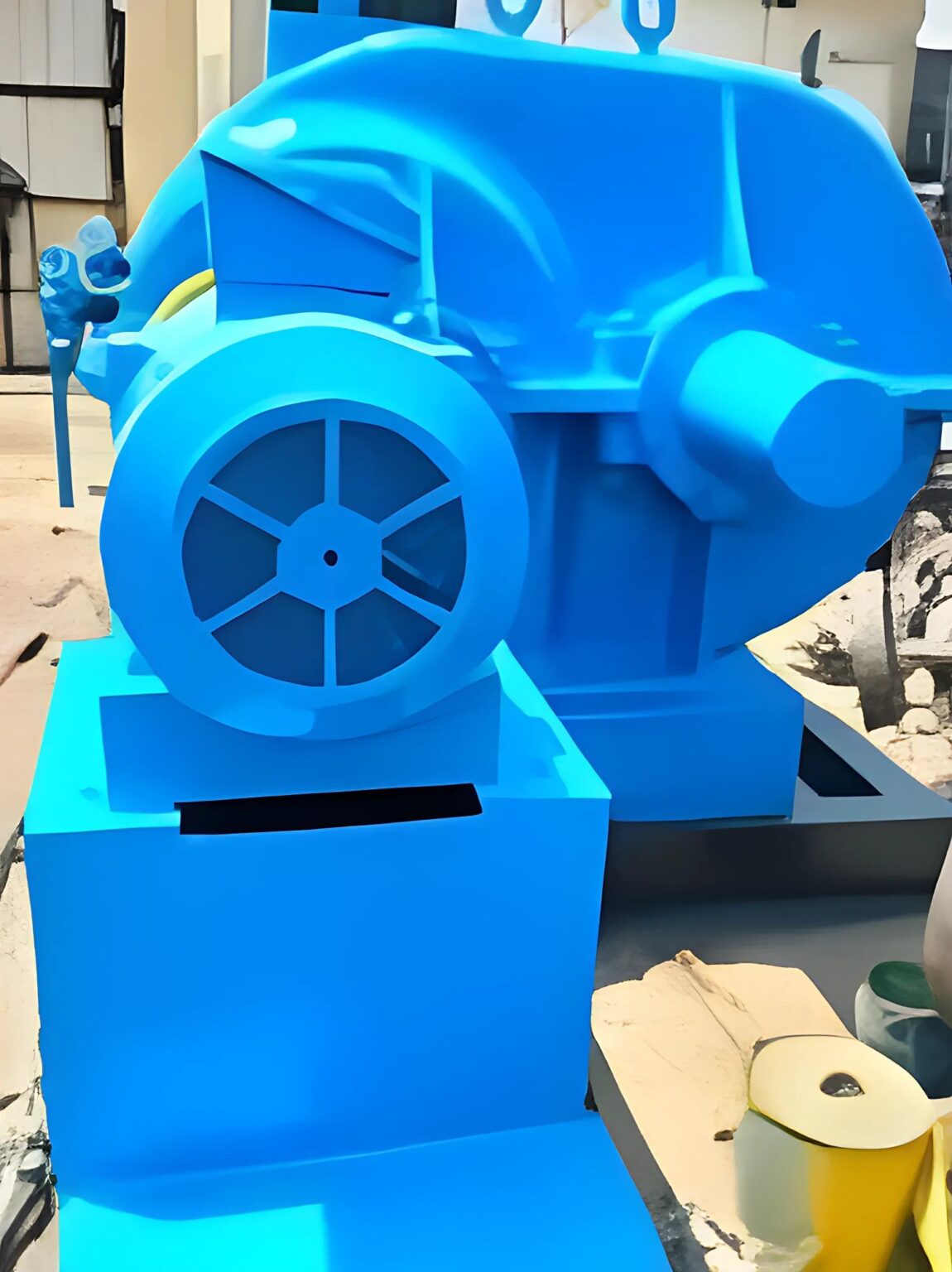

1. Uni-drive Technology: Engineered with advanced Uni-drive technology, this mixing mill ensures optimal performance and consistent mixing results.

2. High-Powered Motor: Equipped with a robust 100 HP motor, this mill delivers high torque and efficiency for all your rubber processing needs.

3. Spacious Design: With dimensions of 22 X 60 inches, this mixing mill offers ample space for large batches, facilitating efficient mixing and processing.

Uses of Uni-drive Rubber Mixing Mill –

i) Rubber Compounding: Perfect for mixing various rubber compounds, ensuring uniformity and consistency in the final product.

ii) Product Development: Ideal for research and development purposes, allowing for experimentation with different rubber formulations and additives.

iii) Production Efficiency: Enhances production efficiency by streamlining the mixing process, reducing downtime, and increasing output.

iv) Quality Assurance: Enables precise control over mixing parameters, leading to superior quality rubber products with consistent properties.

Why Choose Vatsn Tecnic?

Vatsn Tecnic stands as your premier destination for high-quality, secondhand Uni-drive Rubber Mixing Mills in India. With a strong presence in major cities like Delhi, Mumbai, Chennai, Bangalore, and more, we ensure convenient access to top-notch machinery for your business needs.

Our Services –

i) Servicing & Maintenance: We offer comprehensive servicing and maintenance solutions to keep your equipment in peak condition, ensuring uninterrupted operation.

ii) Manpower Assistance: Our skilled technicians provide on-site support and manpower assistance for efficient installation, operation, and troubleshooting.

iii) Annual Maintenance Contracts: Benefit from hassle-free maintenance with our annual maintenance contracts tailored to your specific requirements.

iv) Consultancy Services: Leverage our expertise for business expansion strategies, technical consultation, and process optimization.

Upgrade your rubber processing capabilities with the Uni-drive Rubber Mixing Mill 22 X 60 Motor 100 HP from Vatsn Tecnic. Trust in our commitment to excellence and comprehensive support services for your success in the rubber industry.

For more information Visit here

Compression Molding

Compression Molding