Buy | Sell Used Uni – Drive Rubber Mixing Mill 12 X 30 Motor 30 Hp

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

|

Overall dimension(mm)

|

L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

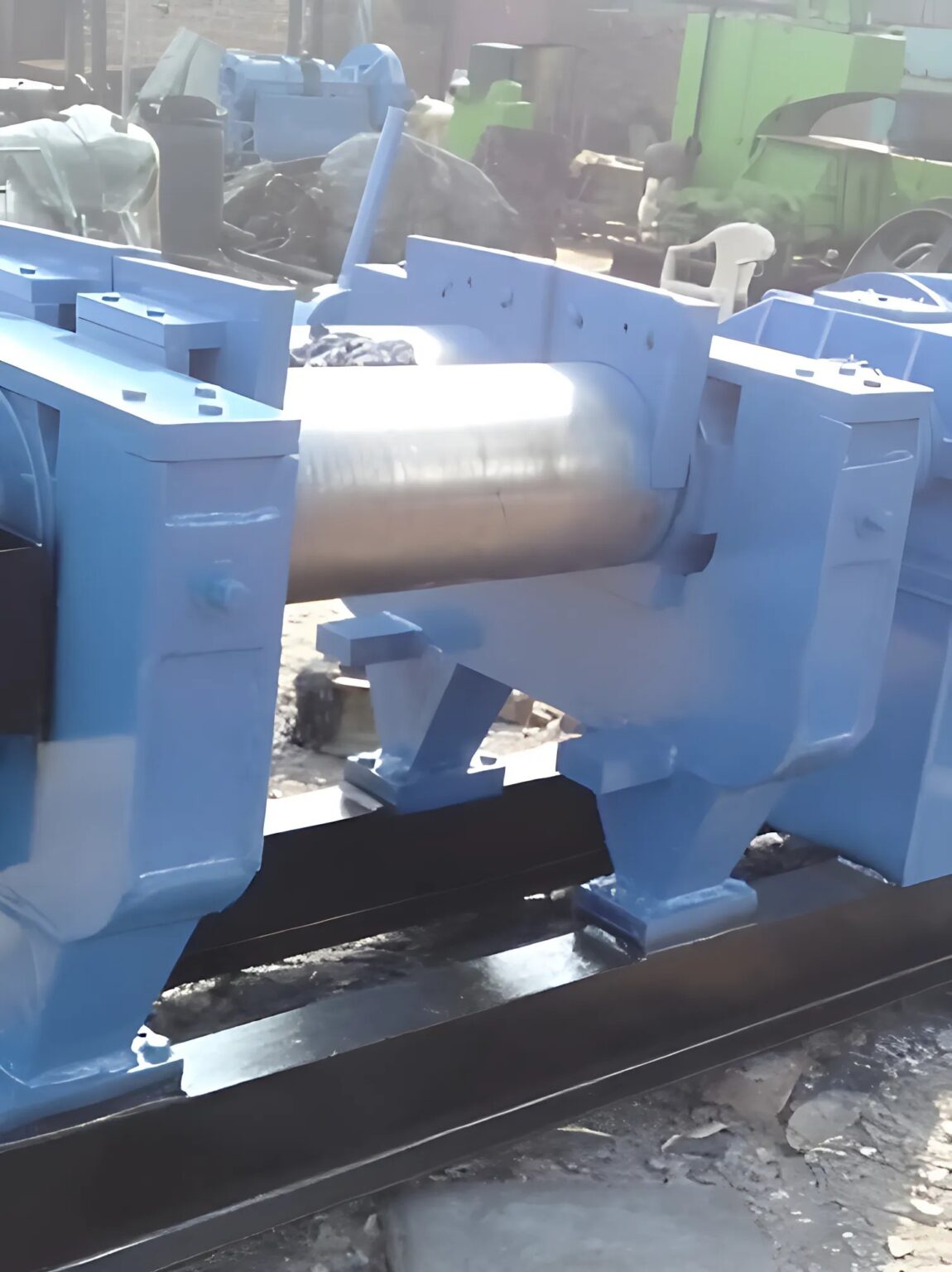

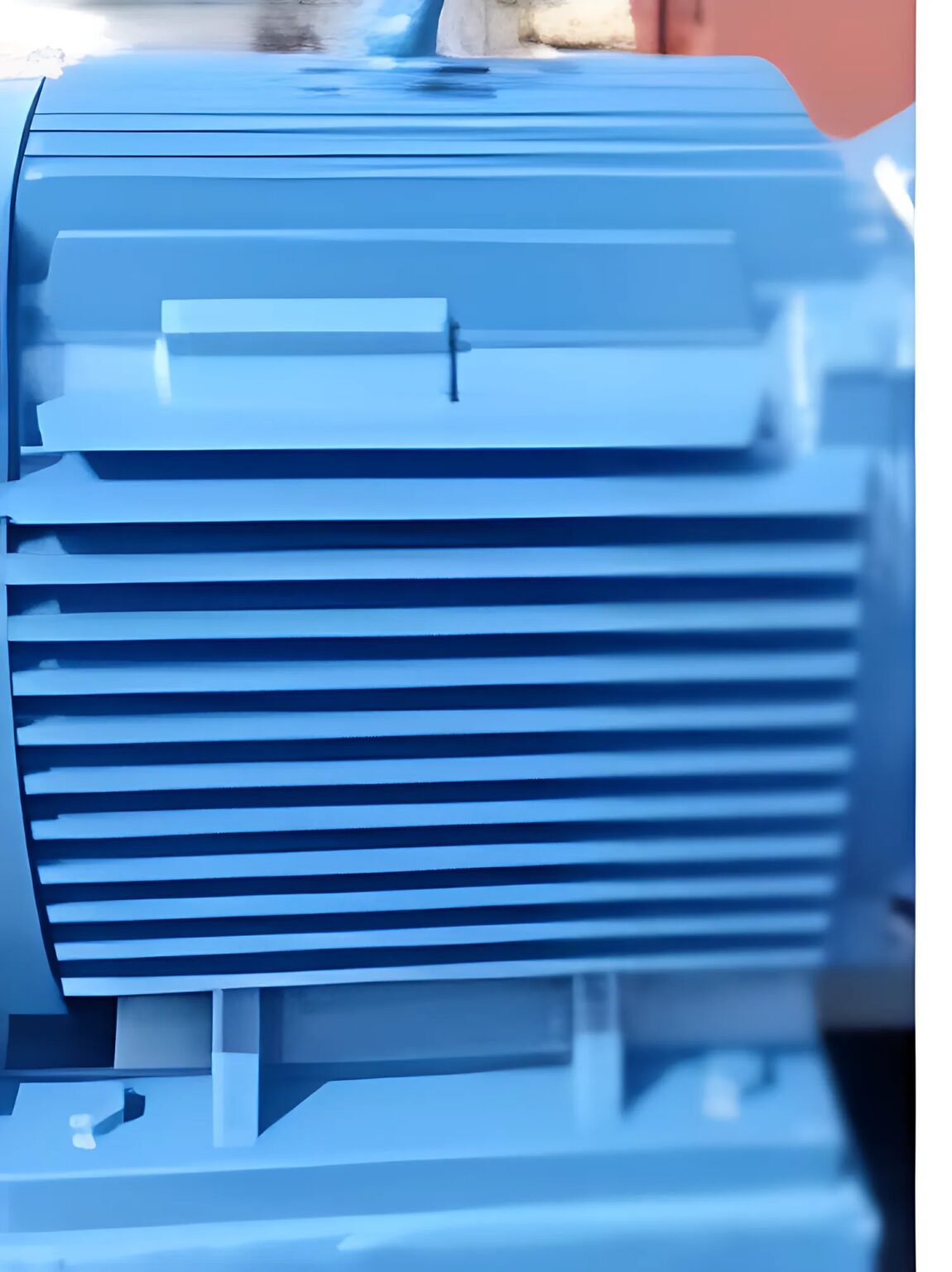

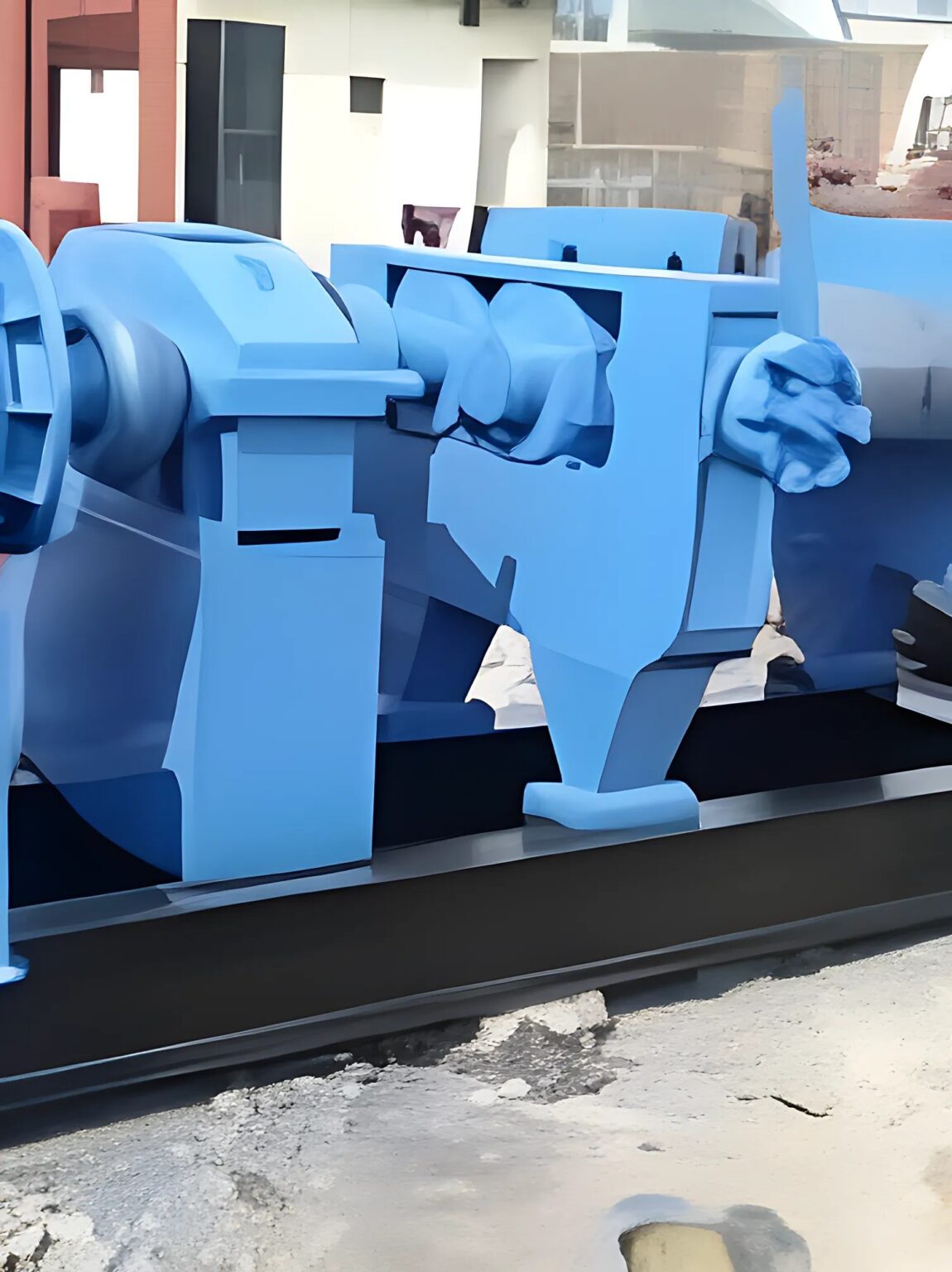

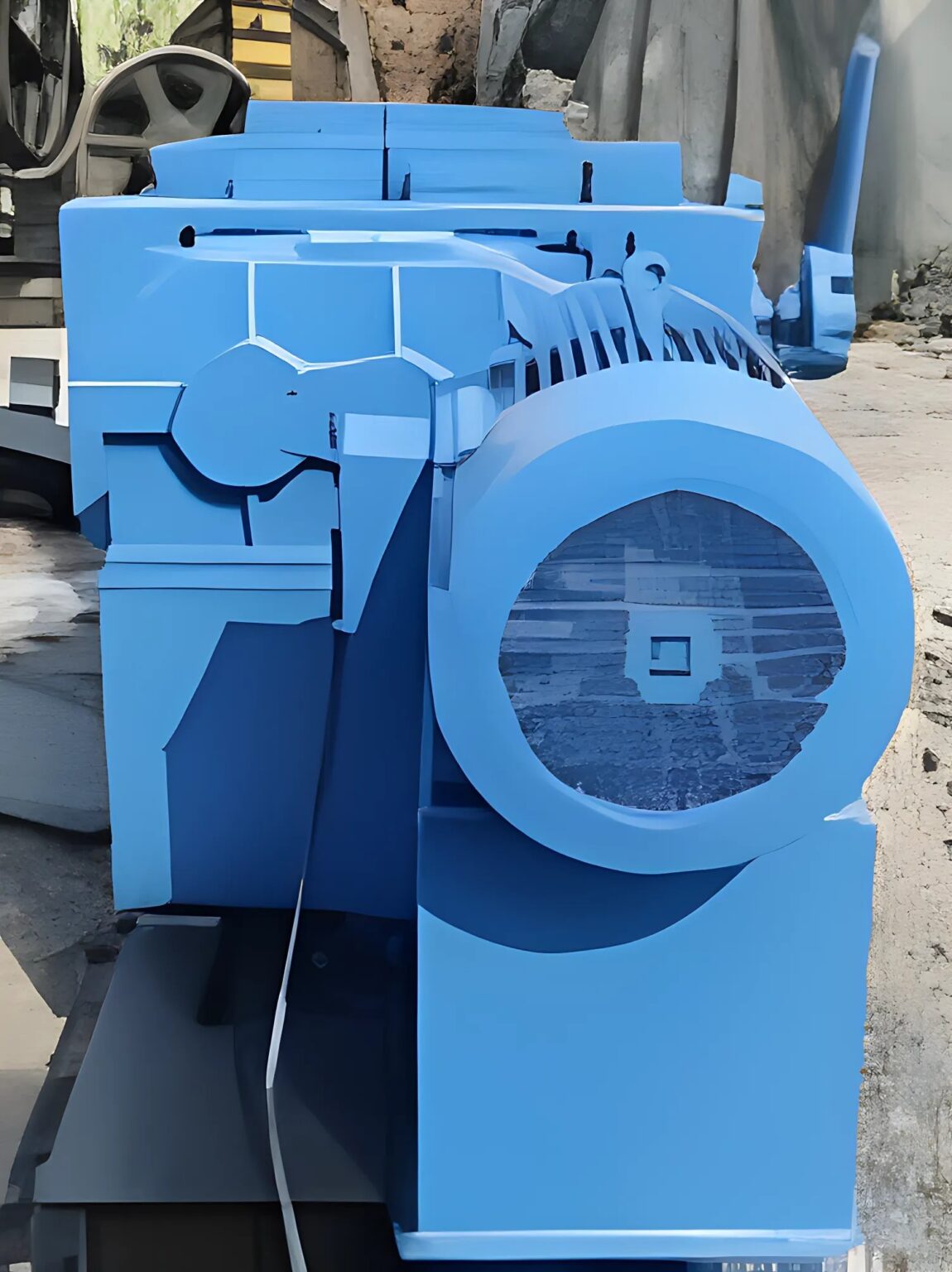

Introducing the Uni Drive Rubber Mixing Mill 12 X 30, equipped with a powerful 30 HP motor, now available for purchase or sale through Vatsn Tecnic. Designed for the precision mixing of rubber compounds, this machinery offers unparalleled performance and reliability in the industrial sector.

The Uni Drive Rubber Mixing Mill serves a myriad of essential functions across various industries –

1. Rubber Processing: Perfect for mixing, kneading, and blending rubber compounds, ensuring uniformity and consistency in the final product.

2. Manufacturing: Ideal for the production of rubber sheets, belts, tires, and other rubber-based products with precise specifications and quality control.

3. Research and Development: Facilitates experimentation and testing of new rubber formulations, enabling innovation and improvement in product performance.

4. Quality Assurance: Guarantees the integrity of rubber compounds by thoroughly mixing ingredients, eliminating air bubbles, and dispersing additives evenly.

5. Customization: Offers flexibility in adjusting mixing parameters to meet the unique requirements of different rubber formulations and applications.

Vatsn Tecnic stands out as a premier destination for procuring and trading secondhand Uni Drive Rubber Mixing Mills in India. With a robust presence in major cities like Delhi, Mumbai, Chennai, Bangalore, and beyond, Vatsn Tecnic ensures accessibility and convenience for its clientele.

Why choose vatsn tecnic?

i) Servicing: Professional maintenance and repair services to keep your machinery in optimal condition, minimizing downtime and maximizing productivity.

ii) Maintenance: Scheduled maintenance programs tailored to your specific needs, prolonging the lifespan of your Uni Drive Rubber Mixing Mill and preventing costly breakdowns.

iii) Manpower: Skilled technicians and engineers available for on-site assistance, troubleshooting, and operational support.

iv) Annual Maintenance Contracts (AMCs): Long-term service agreements ensuring regular upkeep and support for your equipment, providing peace of mind and cost predictability.

v) Consultancy: Strategic guidance and expertise for business expansion initiatives, including capacity enhancement, process optimization, and technological upgrades.

Choose Vatsn Tecnic for unparalleled expertise, reliability, and customer-centric solutions in the realm of Uni Drive Rubber Mixing Mills and beyond. Experience efficiency, quality, and innovation with every transaction.

For more information Visit Here

Compression Molding

Compression Molding