Pre-Owned 90-105kg Hr Rubber Mixing Mill 26 X 84

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

|

Overall dimension(mm)

|

L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

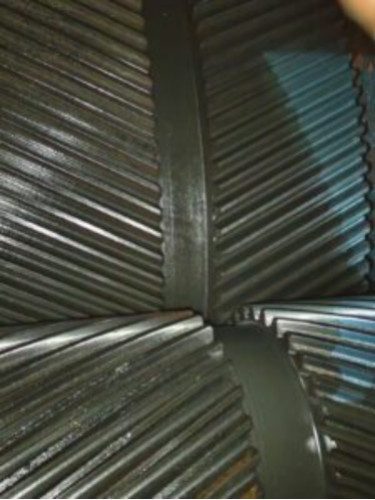

Discover the efficiency and reliability of the Pre-Owned 90-105kg/hr Rubber Mixing Mill 26″ X 84″, a top-tier machine designed for optimal rubber mixing processes. This robust and versatile mill is perfect for manufacturers seeking to enhance their production capabilities while maintaining cost-effectiveness.

Key Features –

i) Capacity: Efficiently processes 90-105kg of rubber per hour, ensuring high productivity.

ii) Size: The 26″ X 84″ dimensions provide ample space for thorough mixing and consistent output.

iii) Durability: Constructed with high-quality materials for long-lasting performance and minimal maintenance.

iv) Precision: Ensures uniform mixing of rubber compounds, crucial for producing high-quality rubber products.

v) Ease of Use: User-friendly controls and ergonomic design for smooth operation and minimal downtime.

Uses of the Rubber Mixing Mill 26″ X 84″ –

i) Rubber Compounding: Ideal for preparing rubber compounds for various applications, including automotive, industrial, and consumer products.

ii) Color Masterbatch Mixing: Perfect for evenly distributing pigments and additives, producing vibrant and consistent colors.

iii) Plasticizing: Efficiently plasticizes rubber to improve the flexibility and durability of the final product.

iv) Recycling: Reprocesses waste rubber materials, promoting sustainability and cost savings.

v) Sheeting: Produces uniform rubber sheets for further processing or direct use in manufacturing.

Why Choose Vatsn Tecnic?

i) Expertise: Vatsn Tecnic is renowned for dealing with secondhand rubber mixing mills, offering only the best performance and reliability.

ii) Nationwide Reach: Operating in major cities across India, including Delhi, Mumbai, Chennai, and Bangalore, ensuring accessibility and support wherever you are.

iii) Comprehensive Services: Providing a full spectrum of services including servicing, maintenance, manpower support, annual maintenance contracts, and business consultancy.

iv) Customer Support: Dedicated to delivering exceptional customer service and support to maximize your investment in rubber machinery.

For more information Visit Here

Compression Molding

Compression Molding