High Performance Rubber Kneader Supplier Rajasthan

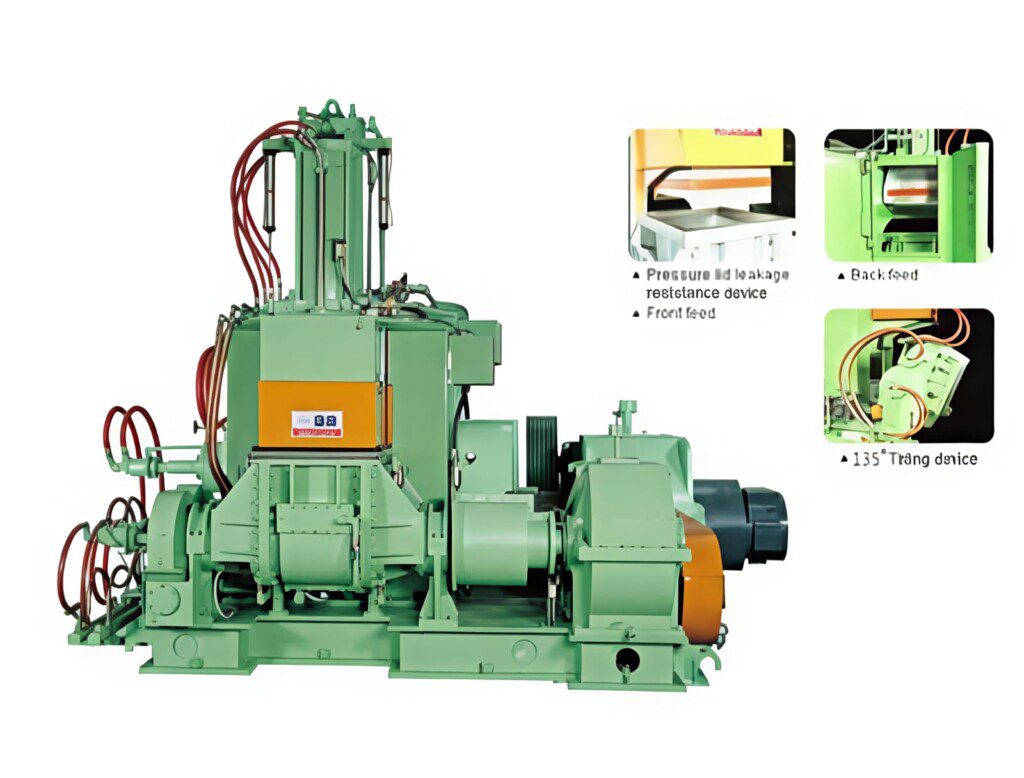

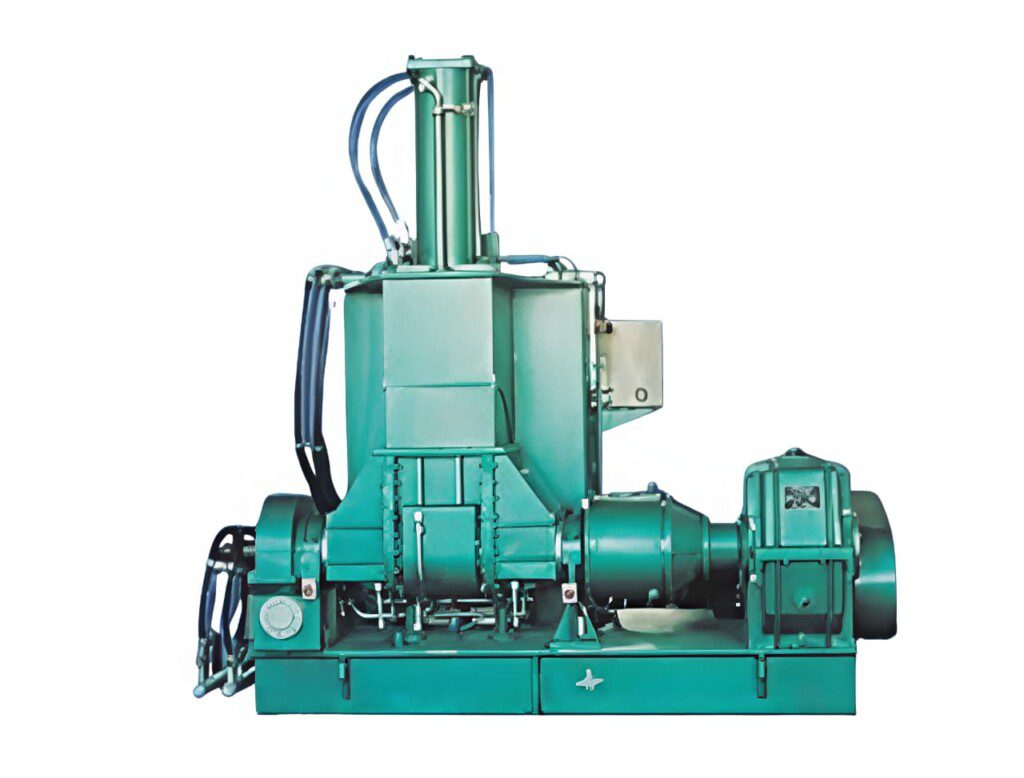

High Performance Rubber Dispersion Kneader Wholesaler in Rajasthan

A high performance Rubber dispersion kneader Wholesaler in Rajasthan supports modern rubber and polymer industries.

Moreover, High performance dispersion kneader supplier in Rajasthan offers strong infrastructure for advanced industrial manufacturing solutions.

Therefore, manufacturers demand efficient machines for consistent compound quality.

In addition, dispersion kneaders improve mixing accuracy across multiple industrial applications.

As a result, production efficiency increases within demanding equipment production units.

Rajasthan-based suppliers focus on quality-driven production system development.

Moreover, they align designs with global industrial manufacturing steps.

Therefore, buyers gain machines suitable for continuous industrial system production line operations.

In addition, these systems support stable output and reduced energy consumption.

High Performance Rubber Dispersion Kneader Wholesaler in Rajasthan for Industrial Manufacturing Steps

A high performance Rubber dispersion kneader Wholesaler in Rajasthan delivers machines for heavy-duty rubber processing.

Moreover, these kneaders support precise temperature and shear control.

Therefore, manufacturers maintain consistency across the production process.

In addition, advanced control panels simplify the machine making process.

As a result, downtime reduces within demanding equipment production units.

Suppliers focus on durability across industrial system production line environments.

Moreover, they select hardened components for long operational life.

Therefore, buyers gain reliable machines for continuous industrial manufacturing steps.

Benefits of a Reliable Production Process in Maharashtra for Industrial System Production Line

A reliable production process supports growth across multiple Indian manufacturing regions.

Moreover, Maharashtra offers strong connectivity and skilled industrial labor.

Key advantages include:

Moreover, stable output improves production system development planning.

Therefore, quality control strengthens across industrial manufacturing steps.

In addition, energy efficiency improves within equipment production units.

As a result, maintenance costs reduce in the machine making process.

Moreover, scalability supports long-term industrial system production line growth.

Therefore, compliance improves with national manufacturing standards.

Government Scheme for Setting Up a Trusted Supplier Supporting Production System Development

Government schemes encourage advanced industrial manufacturing investments.

Moreover, these programs strengthen equipment production units nationwide.

Key scheme benefits include:

Moreover, capital subsidies support modern machine making process investments.

Therefore, tax incentives reduce startup costs for industrial manufacturing steps.

In addition, training programs enhance production system development skills.

As a result, infrastructure grants support industrial system production line expansion.

Moreover, export incentives promote global equipment supply competitiveness.

Major Industrial Areas for Setting Up Industrial Manufacturing Steps

Rajasthan offers several strategic industrial zones for machinery suppliers.

Moreover, these regions support efficient production process planning.

Top industrial zones include:

Moreover, Neemrana supports automotive industrial system production line projects.

Therefore, Bhiwadi attracts advanced equipment production units.

In addition, Jaipur offers skilled manpower for machine making process activities.

As a result, Jodhpur supports heavy engineering industrial manufacturing steps.

Moreover, Udaipur enables mineral-based production system development projects.

How Industrial Systems Are Made | Step-by-Step Manufacturing Process for Equipment Production Units

Industrial systems follow structured industrial manufacturing steps.

Moreover, each stage ensures performance, safety, and durability.

Step 1: Design Planning

Moreover, engineers define specifications for the production process.

Therefore, designs match industrial system production line requirements.

Step 2: Material Selection

In addition, teams choose alloys for the machine making process.

As a result, durability improves across equipment production units.

Step 3: Component Fabrication

Moreover, precision machining supports industrial manufacturing steps.

Therefore, components fit accurately within the production system development plan.

Step 4: Assembly Integration

In addition, technicians assemble parts into the industrial system production line.

As a result, alignment improves during the machine making process.

Step 5: Quality Testing

Moreover, functional tests validate the production process.

Therefore, machines meet industrial manufacturing performance standards.

Step 6: Final Deployment

In addition, systems integrate smoothly into equipment production units.

As a result, output stabilizes across the industrial system production line.

Why Choose VatsnTecnic? for Industrial Machine Manufacturing and Production Process

VatsnTecnic supports advanced industrial manufacturing solutions nationwide.

Moreover, the company focuses on robust production system development.

Key strengths include:

Moreover, proven expertise across industrial manufacturing steps.

Therefore, reliable machines support continuous production process demands.

In addition, technical support ensures smooth machine making process operations.

As a result, clients gain dependable equipment production units.

Moreover, service reliability strengthens industrial system production line performance.

Delhi Government Schemes Supporting Industrial Manufacturing Steps

Delhi offers supportive policies for machinery manufacturers.

Moreover, these schemes encourage modern production system development.

Key initiatives include:

Moreover, capital assistance supports advanced machine making process upgrades.

Therefore, GST benefits reduce industrial manufacturing costs.

In addition, skill programs improve equipment production units efficiency.

As a result, infrastructure access supports industrial system production line growth.

Moreover, startup incentives attract innovative manufacturing High performance dispersion kneader supplier investments.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For more information Visit Here

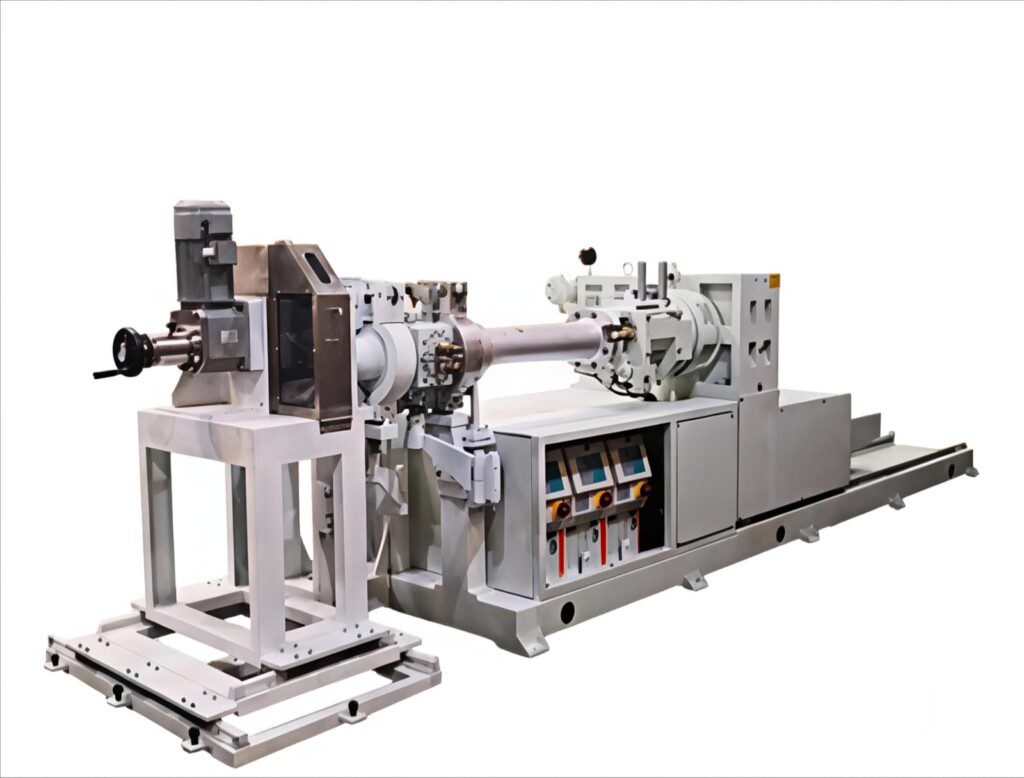

Compression Molding

Compression Molding