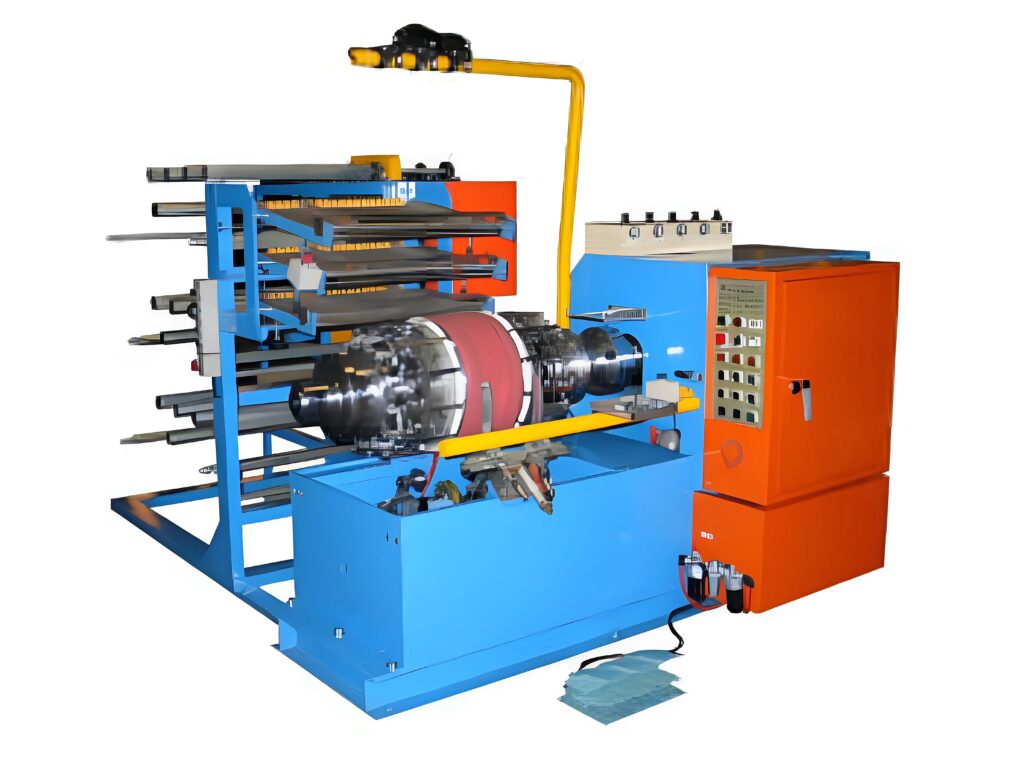

Different Types Pre-Owned Tire Building Machines

In the realm of tire manufacturing, the term “pre-owned” doesn’t just signify cost savings; it also implies reliability, proven technology, and a shorter lead time to get production up and running. Pre-owned machines are essential in the tire industry, ensuring the production of high-quality tires while optimizing costs. Let’s delve into the various types of pre-owned tire-building machines and their significance in the manufacturing process.

1. Passenger Tire Building Machines –

Passenger tire-building machines are designed to produce tires used in standard passenger vehicles. These machines are versatile and can handle various tire sizes, from small cars to mid-size SUVs. Key features include:

- Automated Drum Systems: These systems streamline the tire-building process, ensuring precision and consistency.

- Green Tire Uniformity: Ensures the even distribution of materials, reducing the risk of tire imbalance.

- User-Friendly Interface: Allows operators to easily set parameters and monitor the building process.

Popular Models:

- VMI MAXX Tyre Building Machine

- Pirelli MIRS (Modular Integrated Robotized System)

2. Truck and Bus Tire Building Machines –

These machines cater to the heavy-duty requirements of truck and bus tires, which demand durability and strength. They are built to handle larger and heavier tire components.

- Robust Construction: Designed to withstand the rigors of heavy tire components.

- Advanced Automation: Features like robotic arms and automated stitching increase efficiency and accuracy.

- Multi-Stage Building Process: Often includes multiple stages to ensure the tire can handle high loads and long-distance travel.

Popular Models:

- Continental CTC Truck Tire Building Machine

- Goodyear TBM (Truck and Bus Machine)

3. Agricultural Tire Building Machines –

Agricultural tires are used in tractors, harvesters, and other farming equipment, necessitating machines that can handle large, heavily treaded tires.

- Heavy-Duty Frame: Supports the large dimensions and heavy weight of agricultural tires.

- Customization Options: Capable of producing tires with various tread patterns and sizes.

- High Torque Capabilities: Essential for handling the substantial rubber components involved.

Popular Models:

- Harburg-Freudenberger Agricultural Tire Building Machine

- Marangoni Tire Building Systems

4. Motorcycle Tire Building Machines –

Motorcycle tires require precision for balance and performance, making these machines specialized and highly accurate.

- Precision Engineering: Ensures perfect roundness and uniformity for high-speed performance.

- Compact Design: Suitable for the smaller-size of motorcycle tires.

- Quick Changeover: Allows for rapid switching between different tire sizes and types.

Popular Models:

- Bartell Motorcycle Tire Building Machine

- Berstorff Tire Building Equipment

5. Specialty Tire Building Machines

Specialty tires include those used in aviation, construction, and mining. Each of these applications requires unique tire characteristics.

- Customizable Settings: Tailored to meet the specific requirements of different specialty tires.

- High Durability: Built to handle the extreme conditions these tires will face.

- Advanced Control Systems: Ensures precision in building complex tire structures.

Popular Models:

- Michelin Aircraft Tire Building Machine

- Bridgestone Mining Tire Building System

Benefits of Pre-Owned Tire Building Machines –

Investing in pre-owned tire-building machines comes with several advantages:

- Cost-Effective: Significant savings compared to purchasing new equipment.

- Reduced Lead Time: Machines are often available immediately, avoiding the long wait times associated with new orders.

- Proven Reliability: Established machines with a track record of performance.

- Sustainability: Extending the life cycle of machinery reduces environmental impact.

For more information Visit Here

Compression Molding

Compression Molding