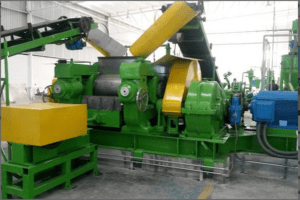

Best Quality Used Waste Tire Recycling Line XKP-350/400/450/560/660

Today, environmental sustainability is crucial. Industries worldwide seek innovative solutions to cut waste and shrink their ecological footprint. Used tires contribute to waste accumulation. Disposing of old tires poses environmental hazards, from soil contamination to fire risks. But, technology has advanced. We now have efficient ways to recycle waste tires. This reduces their harm to the environment. Among these solutions, the Waste Tire Recycling Line XKP series stands out. It is a beacon of innovation and sustainability.

1. Understanding Waste Tyre Recycling Machine –

Recycling machines process discarded tires into valuable materials like rubber powder. Many industries, such as cars, construction, and manufacturing, can use it. These machines are crucial for environmental conservation. They reduce the volume of waste tires in landfills. They stop harmful pollutants from contaminating the environment.

The XKP series are waste tire recycling lines. They include models XKP 350, 400, 450, 560, and 660. They are known for processing many types of tires. These machines use advanced tech. They ensure high-quality output. They also cut energy use and operational costs.

2. Exploring the Differences Between XKP 350/400/450/560/660 –

While all models in the XKP series serve the same purpose of recycling waste tires, they differ in terms of processing capacity, power consumption, and specific features:

i) XKP 350: This model is designed for smaller-scale operations, offering a processing capacity suited for moderate volumes of waste tires.

ii) XKP 400: With enhanced capabilities, the XKP 400 can handle a higher volume of tires compared to the XKP 350, making it suitable for medium-sized tire recycling facilities.

iii) XKP 450: Stepping up in capacity, the XKP 450 is capable of processing even larger quantities of waste tires, catering to facilities with higher throughput requirements.

iv) XKP 560: This model represents a significant advancement in processing capacity, making it ideal for large-scale tire recycling operations. It offers increased efficiency and throughput, allowing for more tires to be recycled within a given timeframe.

v) XKP 660: The XKP 660 stands at the top of the XKP series, boasting the highest processing capacity among its counterparts. This model is suitable for industrial-scale tire recycling facilities, capable of handling vast quantities of waste tires with ease.

3. Choosing a Trusted Supplier: Vatsn Tecnic

When investing in a waste tire recycling line, choosing a reliable and reputable supplier is paramount to ensure product quality, technical support, and after-sales service. Vatsn Tecnic emerges as a trusted supplier of the XKP series, offering comprehensive solutions tailored to the specific needs and requirements of customers.

Vatsn Tecnic’s commitment to excellence is reflected in its stringent quality control measures, cutting-edge manufacturing processes, and continuous innovation. With a team of experienced engineers and technicians, Vatsn Tecnic delivers superior products and services, ensuring customer satisfaction and long-term success.

Conclusion

In conclusion, the XKP series of waste tire recycling lines represents a significant advancement in sustainable waste management practices. These machines not only provide an effective solution for recycling waste tires but also contribute to environmental preservation and resource conservation. With the support of trusted suppliers like Vatsn Tecnic, businesses can embark on their journey towards a greener and more sustainable future.

For more information Visit Here

Compression Molding

Compression Molding