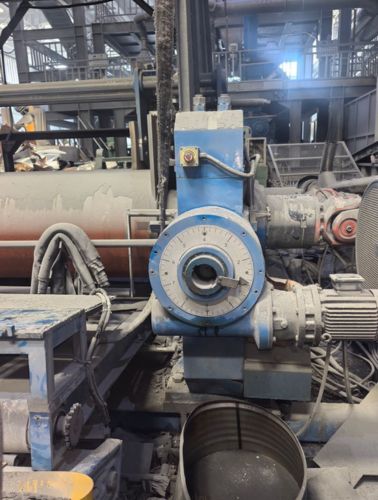

160L Rubber Mixer with Two-Roll Mill & Calender

160L Rubber Mixer with Two-Roll Mill & Calender – Complete Production Solution

Setting up a 160L Rubber Mixer with Two-Roll Mill & Calender gives rubber manufacturers a powerful, integrated solution for high-volume and consistent rubber processing. This heavy-duty rubber mixing line supports industries such as footwear, Industrial Rubber Processing Plant automotive components, conveyor belts, rubber sheets, and molded rubber products. Moreover, when you combine a 160-liter internal mixer with a two-roll mill and calender, you gain full control over compounding, sheeting, and finishing operations.

In today’s competitive rubber industry, efficiency and quality matter more than ever. Therefore, investing in a 160L Rubber Mixer with Two-Roll Mill & Calender system ensures stable output, reduced wastage, and scalable production.

Benefits of Installing a 160L Rubber Mixer with Two-Roll Mill & Calender System

A 160L Rubber Mixer with Two-Roll Mill & Calender line delivers multiple operational and financial advantages. Industrial Rubber Processing Plant First of all, it significantly improves batch consistency, which directly impacts final product quality. Additionally, it supports continuous and large-scale production without frequent downtime.

Another key benefit is cost optimization. Since the system integrates mixing, refining, and calendering, manufacturers reduce manual handling and labor dependency. As a result, productivity increases while operational costs decrease.

Furthermore, this rubber processing setup offers flexibility. You can process natural rubber, synthetic rubber, EVA, and other compounds with ease. At the same time, robust construction ensures long service life, even under heavy industrial loads.

Government Schemes for Setting Up a 160L Rubber Mixer with Two-Roll Mill & Calender Unit

When planning a 160L Rubber Mixer with Two-Roll Mill & Calender manufacturing setup, government schemes can reduce capital burden. Below are five short and relevant schemes commonly used in India:

MSME Subsidy Schemes – Provide financial support and easier credit access for rubber machinery units.

PMEGP (Prime Minister’s Employment Generation Programme) – Offers margin money subsidy for new manufacturing projects.

CLCSS (Credit Linked Capital Subsidy Scheme) – Helps upgrade rubber processing machinery with reduced loan interest.

State Industrial Development Subsidies – Many states offer land, power, and tax incentives.

Stand-Up India Scheme – Supports entrepreneurs with funding for industrial machinery projects.

Therefore, leveraging these schemes makes a 160L Rubber Mixer with Two-Roll Mill & Calender investment more affordable and sustainable.

Major Industrial Areas for 160L Rubber Mixer with Two-Roll Mill & Calender Installation

Choosing the right location plays a crucial role in operational success. Below are five major industrial regions ideal for a 160L Rubber Mixer with Two-Roll Mill & Calender – Perfect Working Condition setup:

Delhi NCR – Strong supplier network and logistics support.

Punjab (Ludhiana, Jalandhar) – Hub for rubber and footwear manufacturing.

Tamil Nadu (Coimbatore, Chennai) – Skilled labor and export-driven rubber industry.

Maharashtra (Pune, Mumbai region) – Excellent infrastructure and industrial policies.

Gujarat (Ahmedabad, Vapi) – Cost-effective power and raw material access.

As a result, these regions ensure smooth operations and faster market reach.

Why Choose Vatsntecnic for 160L Rubber Mixer with Two-Roll Mill & Calender?

When it comes to sourcing a 160L Rubber Mixer with Two-Roll Mill & Calender, choosing the right partner matters. Vatsntecnic stands out due to its industry expertise and commitment to quality. We supply thoroughly inspected machines that deliver reliable performance and long-term value.

Moreover, Vatsntecnic offers transparent guidance, technical support, and end-to-end assistance—from selection to installation. We understand rubber processing requirements deeply, so we recommend solutions that match your production goals.

Most importantly, our focus remains on customer success. Whether you need a new setup or a cost-effective pre-owned solution, Vatsntecnic ensures you invest with confidence.

For more information Visit Here

You must be logged in to post a review.

Compression Molding

Compression Molding

Reviews

There are no reviews yet.