Rubber Compression Molding Process in Punjab

Rubber Compression Molding Process in Punjab | Industrial System Production Line

The rubber compression molding process in Punjab supports growing industrial rubber manufacturing demand.

Moreover, Punjab offers reliable infrastructure for a stable production process.

Therefore, manufacturers prefer controlled industrial manufacturing steps for consistent molded components.

In addition, structured production system development improves molding accuracy and cycle efficiency.

As a result, equipment production units perform smoothly across the industrial system production line.

Benefits of a Reliable Production Process in Maharashtra | Industrial Manufacturing Steps

A reliable production process strengthens rubber compression molding efficiency across industries.

Moreover, standardized industrial manufacturing steps ensure consistent pressure and temperature control.

Therefore, production system development supports repeatable molding results.

In addition, an optimized machine making process reduces material loss.

As a result, equipment production units deliver stable output on the industrial system production line.

Government Scheme for Setting Up a Trusted Supplier | Production System Development

Government schemes help strengthen production system development for rubber compression molding businesses.

Moreover, policy support encourages adoption of advanced machine making process technologies.

Therefore, manufacturers invest confidently in equipment production units.

In addition, industrial development support lowers financial risk.

As a result, the industrial system production line expands sustainably.

Major Industrial Areas for Setting Up | Industrial System Production Line

Punjab offers several industrial zones ideal for rubber compression molding operations.

Moreover, these areas support efficient industrial manufacturing steps execution.

Therefore, manufacturers gain access to skilled labor and logistics.

In addition, infrastructure readiness improves equipment production units efficiency.

As a result, production process timelines remain controlled.

How Industrial Systems Are Made | Step-by-Step Manufacturing Process Using Production Process

Rubber compression molding follows a disciplined production process for reliable component formation.

Moreover, planning starts with production system development and mold design evaluation.

Therefore, engineers define industrial manufacturing steps precisely.

In addition, compound preparation follows strict machine making process standards.

As a result, equipment production units integrate efficiently into the industrial system production line.

Why Choose VatsnTecnic? | Industrial Manufacturing Steps & Machine Making Process

VatsnTecnic delivers dependable solutions aligned with industrial manufacturing steps.

Moreover, the company emphasizes a controlled production process approach.

Therefore, clients receive reliable production system development support.

In addition, expert teams manage the machine making process professionally.

As a result, equipment production units maintain long-term operational reliability.

Delhi Government Schemes | Equipment Production Units & Production Process

Moreover, capital subsidy schemes support production process expansion

Therefore, interest reimbursement programs reduce equipment production units costs

In addition, technology upgradation incentives improve machine making process

As a result, industrial manufacturing steps become more efficient

Moreover, export-linked benefits strengthen the industrial system production line

The rubber compression molding process in Punjab enables consistent industrial rubber production.

Moreover, structured industrial manufacturing steps reduce operational variability.

Therefore, a stable production process improves output reliability.

In addition, production system development supports scalable manufacturing growth.

As a result, the industrial system production line achieves long-term efficiency.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For more information Visit Here

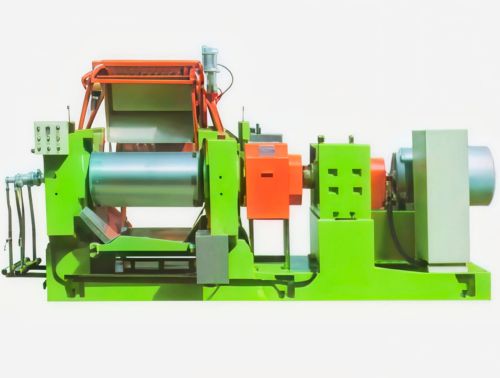

Compression Molding

Compression Molding