Hot Feed Rubber Extruder Machine in Jharkhand

Hot Feed Rubber Extruder Machine in Jharkhand for Industrial Manufacturing Growth

- Jharkhand is emerging as a strong industrial manufacturing destination.

Moreover, rubber machinery demand continues growing across eastern India.

Therefore, Hot Feed Rubber Extruder Machine in Jharkhand offers strong business opportunities. - The production process of rubber extrusion requires precision machinery.

In addition, industrial manufacturing steps depend on consistent extrusion quality.

As a result, manufacturers prefer advanced hot feed extruder systems. - Jharkhand supports rubber processing through infrastructure and skilled manpower.

Moreover, the region supports production system development across industries.

Therefore, extruder equipment production units perform efficiently here.

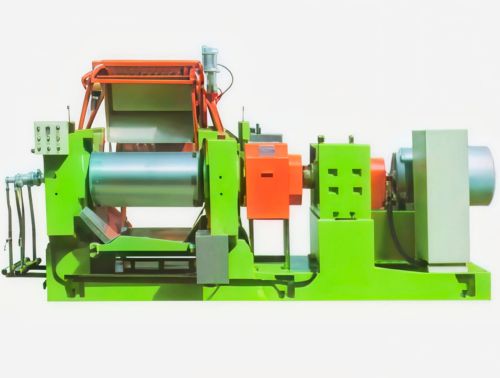

Hot Feed Rubber Extruder Machine in Jharkhand and Industrial Manufacturing Steps

- The machine making process begins with material feeding systems.

Moreover, hot feed extruders process rubber compounds without preheating.

Therefore, production process efficiency improves significantly. - Industrial manufacturing steps include screw rotation and barrel heating.

In addition, controlled pressure ensures uniform rubber flow.

As a result, product quality remains consistent. - Jharkhand manufacturers benefit from stable power availability.

Moreover, logistics networks reduce material transportation delays.

Therefore, production system development remains cost-effective.

Benefits of Setting Up Hot Feed Rubber Extruder Machine in Jharkhand Production Process

- Setting up a Hot Feed Rubber Extruder Machine in Jharkhand offers several advantages.

Moreover, local resources support continuous industrial manufacturing steps. - Lower operational costs improve production process efficiency.

Moreover, skilled labor availability supports machine making process accuracy. - Raw material sourcing remains economical within eastern India.

Therefore, equipment production units gain better margins. - Jharkhand provides industrial land at competitive prices.

In addition, state policies encourage manufacturing investments. - Transport connectivity supports faster market access.

As a result, production system development scales smoothly. - Energy costs remain comparatively lower.

Therefore, industrial manufacturing steps stay profitable.

Government Scheme for Trusted Supplier

The Jharkhand government actively promotes rubber machinery manufacturing across industrial zones. Moreover, trusted supplier status improves market credibility and buyer confidence. Capital subsidy schemes support new machinery investments and reduce initial financial pressure. Moreover, MSME registration offers financial incentives and easier credit access. Interest subsidies reduce long-term financing burdens significantly. Therefore, production process expansion becomes faster and more sustainable. GST benefits support equipment production units and improve cash flow efficiency. In addition, startup policies encourage innovation and technology adoption. Skill development programs improve workforce efficiency and technical accuracy. As a result, machine making process quality improves consistently. Infrastructure support reduces setup timelines across industrial areas. Therefore, production system development accelerates with stable government backing. Moreover, export promotion schemes help manufacturers reach global markets. In addition, single-window clearance systems simplify approvals and speed project execution.

Major Industrial Areas

- Choosing the right location ensures smooth industrial manufacturing steps.

Moreover, Jharkhand offers multiple industrial zones. - Adityapur Industrial Area supports heavy machinery production.

Moreover, supply chains remain well-connected. - Bokaro Industrial Area offers steel and engineering support.

Therefore, machine making process becomes easier. - Ranchi Industrial Corridor supports MSME growth.

In addition, skilled technicians are available. - Dhanbad Industrial Zone supports energy-based manufacturing.

As a result, production process efficiency improves. - Jamshedpur Industrial Region offers strong vendor ecosystems.

Therefore, equipment production units grow faster.

Hot Feed Rubber Extruder Machine in Jharkhand Equipment Production Units and Applications

- Hot feed extruders support various rubber product manufacturing needs.

Moreover, industries prefer consistent extrusion output. - These machines produce rubber profiles and strips.

In addition, hoses and seals benefit from hot feed extrusion. - Tire and automotive sectors demand high-output extruders.

Therefore, industrial manufacturing steps require robust designs. - Construction rubber components rely on extrusion accuracy.

As a result, production system development remains stable.

Hot Feed Rubber Extruder Machine in Jharkhand Production System Development Workflow

- The workflow starts with raw rubber feeding.

Moreover, screws convey material efficiently. - Heating zones maintain controlled temperatures.

Therefore, rubber plasticity improves. - Extrusion heads shape rubber profiles precisely.

In addition, cooling systems stabilize output. - Cutting units finalize product dimensions.

As a result, production process completes efficiently.

Why Choose VatsnTecnic

VatsnTecnic designs machines with strong industrial expertise and practical knowledge. Moreover, precision engineering ensures long service life and stable performance. The company follows structured production system development methods. Therefore, machine performance remains consistent across operating conditions. VatsnTecnic uses high-grade components for durability and efficiency. In addition, quality checks follow strict standards at every stage. Customized solutions support specific industrial manufacturing steps effectively. As a result, clients achieve higher productivity and better output control. Technical support ensures minimal downtime during operations. Therefore, equipment production units operate smoothly and reliably. VatsnTecnic understands Indian manufacturing requirements clearly. Moreover, machines suit Jharkhand’s industrial conditions and operational needs.

Future Scope of Hot Feed Rubber Extruder Machine in Jharkhand Production Process

Rubber demand continues growing across infrastructure sectors.

Moreover, automotive expansion drives extrusion needs.

Jharkhand supports long-term industrial investments.

Therefore, production system development shows strong potential.

Advanced machinery adoption improves global competitiveness.

As a result, equipment production units expand rapidly.

Final Note

Hot Feed Rubber Extruder Machine in Jharkhand offers strong manufacturing potential.

Moreover, government support enhances business confidence.

Therefore, choosing the right supplier ensures long-term success.

For more information Visit Here

https://www.indiamart.com/vatsntecnic/profile.html

Compression Molding

Compression Molding