Rubber Refiner Mixing Mill in Kerala Setup Guide

Rubber Refiner Mixing Mill in Kerala: A Complete Guide for Investors and Manufacturers

Rubber Refiner Mixing Mill in Kerala is gaining strong interest from industry and startups. Kerala’s growth in rubber products makes this topic important. In this blog, we explain benefits, schemes, locations, steps to start, and why you should partner with Vatsntecnic.

Why Start a Rubber Refiner Mixing Mill in Kerala?

Rubber mixing mills help refine raw rubber. They blend additives and make high-quality compounds. Setting up in Kerala brings many advantages.

1. Strong Raw Material Access

Kerala has abundant rubber farms. As a result, mills enjoy local supply. This lowers transport costs. It also reduces delays in production.

2. Skilled Workforce Nearby

Many trained workers in rubber processing live in Kerala. They understand mixing and refining. So, you save on training time.

3. Growing Local Demand

Rubber goods like tyres and belts are in demand. Local manufacturers want quality compounds. Therefore, a mixing mill finds buyers easily.

4. Strategic Port Connections

Kerala’s ports link to global markets. This helps export rubber products. Consequently, you expand business beyond India.

5. Supportive Business Climate

The state government supports MSMEs. It offers permits and clearances fast. So, starting a mill becomes easier.

Government Scheme for Trusted Supplier of Rubber Dispersion Kneader Machines in Delhi

If you plan to source or supply machinery like rubber dispersion kneaders, it helps to know government support. Here are key schemes and points that can help your business.

1. Credit Guarantee Scheme

The government offers credit support. This helps small machine suppliers get loans without heavy collateral.

2. Capital Subsidy for Machinery

Eligible units may get money back for machine purchases. This reduces upfront costs.

3. Subsidised Electricity and Infrastructure

Industrial zones often provide cheaper power. They also give reliable roads and water.

4. MSME Technology Upgradation Fund

The fund helps buy modern equipment. This includes trusted rubber dispersion kneader machines.

5. Startup India Benefits

New businesses in Delhi can access tax holidays. They also get easier registration.

These schemes boost reliable suppliers in the rubber machine market.

Best Industrial Areas to Set Up Rubber Refiner Mixing Mill in Kerala

Choosing the right area reduces costs. It increases logistics efficiency. Here are five major industrial zones to consider.

1. Kochi Industrial Growth Belt

Kochi has ports and highways. It links to major rubber markets.

2. Thrissur Rubber Cluster

Thrissur has many rubber small businesses. This creates local demand.

3. Kottayam Industrial Zone

Kottayam’s proximity to plantations helps raw material access.

4. Palakkad Special Economic Zone

Palakkad offers tax benefits and good infrastructure.

5. Kozhikode Industrial Park

This area connects north Kerala to national highways.

Step-by-Step: How to Start a Rubber Mixing Mill in Kerala

Starting a mixing mill needs clear planning. Here are five steps that guide you.

1. Market Research and Planning

Study demand, pricing, and competition. Create a solid business plan.

2. Register Your Business

Choose the right legal structure. Apply for GST, and MSME registration.

3. Secure Land and Licences

Pick an industrial area. Get environmental and safety clearances.

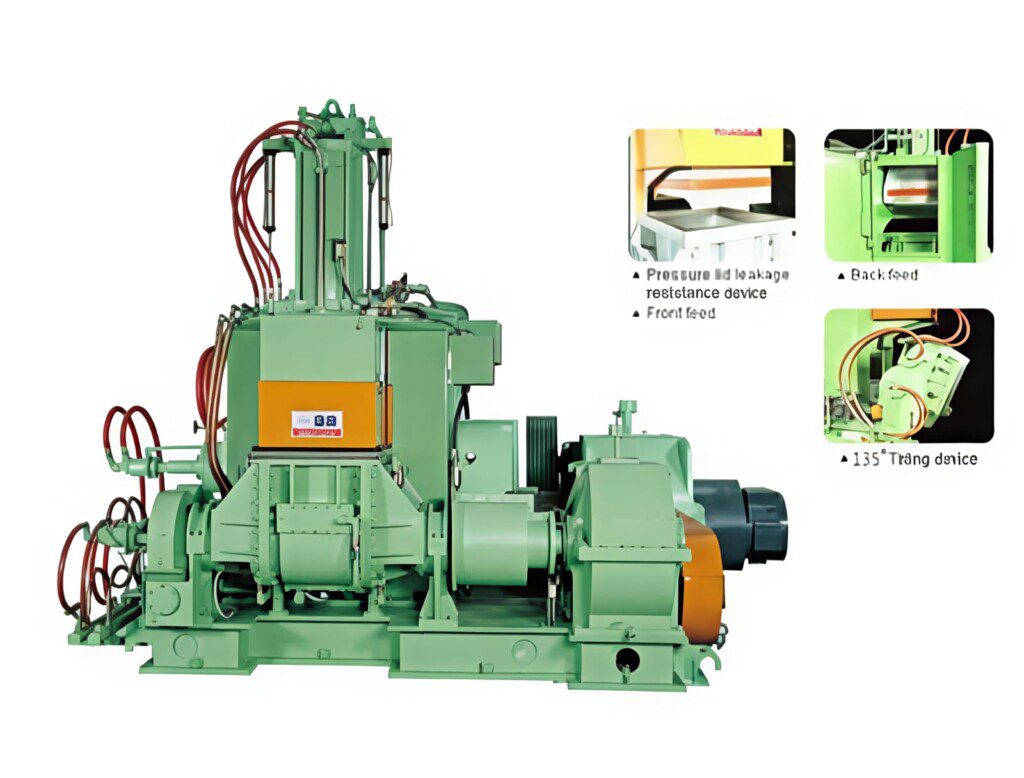

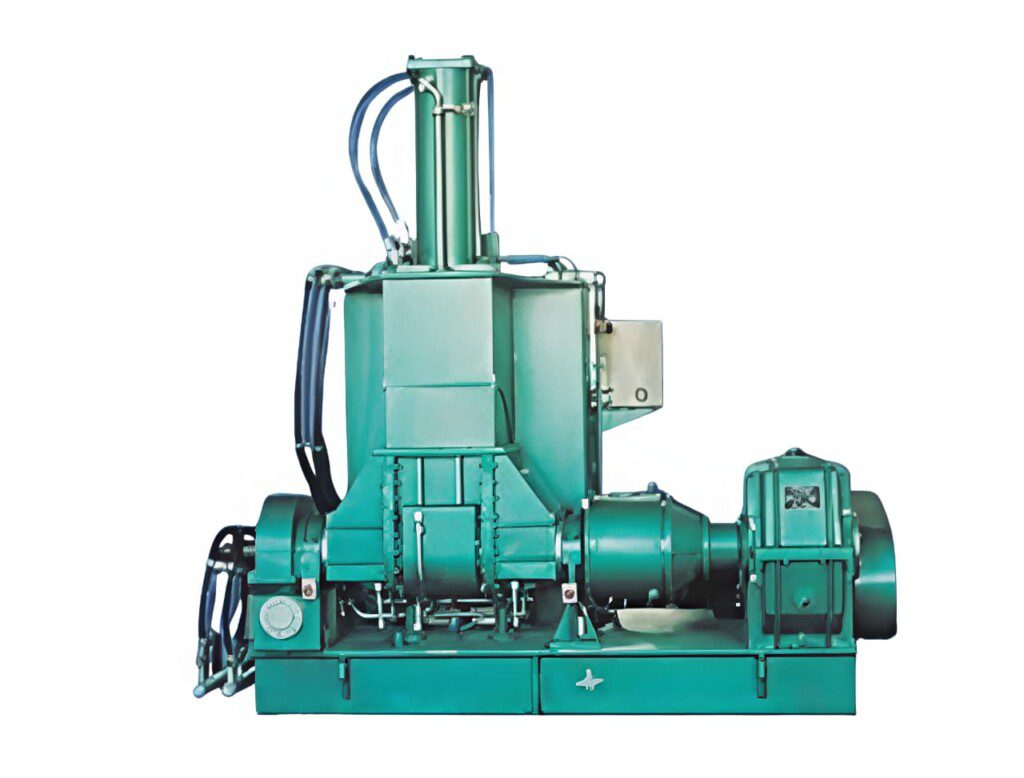

4. Buy Equipment

Invest in good rubber refiner and dispersion kneader machines. Ensure quality and service support.

5. Hire and Train Staff

Recruit skilled workers. Train them for safety and quality control.

How Rubber Refiner Mixing Mill in Kerala Helps the Conveyor Belt Industry

The quality of raw compounds affects final products. Conveyor belts need strong, uniform rubber mixes. Here’s why mills matter.

Consistent Quality

Mixing mills ensure uniform blending. This improves performance.

Better Strength of Belts

Uniform compound leads to strong belts. It also increases lifespan.

Lower Production Waste

Good refining reduces rejects. So, costs drop.

Faster Turnaround

Automated mills speed up production. This helps meet deadlines.

Support for Innovation

High-quality mixes allow new belt designs. This opens new markets.

Why Choose Vatsntecnic for Rubber Mixing and Conveyor Solutions

When choosing partners for rubber machinery, pick a brand you can trust. Vatsntecnic stands out for several reasons.

1. Proven Machinery Performance

Vatsntecnic machines deliver stable results. You get consistent rubber mixes every batch.

2. Excellent After-Sales Support

Great service after purchase makes operations smooth. Skilled technicians help quickly.

3. Competitive Pricing

Their machines balance cost and performance. This suits startups and big units.

4. Custom Solutions for Your Mill

They offer machines tailored to your needs. So, your mill runs efficiently.

5. Strong Reputation in the Market

Many manufacturers trust Vatsntecnic. Their products are reliable and durable.

Key Tips for Running a Successful Rubber Refining Mill in Kerala

To grow your mill, follow these best practices.

Focus on Quality Control

Test rubber blends frequently. Use standard lab tools.

Maintain Safety at Work

Provide gear for workers. Follow safety rules every day.

Build a Reliable Supplier Network

Source raw rubber from trusted farms. This stabilises input quality.

Promote Your Finished Compounds

Use online marketing and local fairs. Reach tyre makers, belt producers, and rubber product units.

Plan for Expansion

As demand grows, add new machines. Consider new zones for branches.

Common Challenges in Rubber Refiner Mixing Mill in Kerala

Running a mill brings challenges. But you can solve them with planning.

Raw Material Price Fluctuations

Rubber prices change. Sign long-term contracts to manage costs.

Skilled Labor Shortage

Train local workers. Use certification programs.

Environmental Compliance

Follow emissions and waste rules. Use modern filters.

Energy Costs

Choose energy-efficient machines. This saves money.

Market Competition

Offer value-added services. Stand out with quality.

Conclusion: Make Your Rubber Refiner Mixing Mill in Kerala Successful

Kerala is a strategic place for a rubber refining mill. You get raw material access, skilled workers, and demand. Government schemes also support machinery suppliers. Choose the right location. Follow step-by-step setup plans. Finally, collaborate with trusted machine brands like Vatsntecnic to ensure quality and business growth.

Vatsntecnic

For more information Visit Here

Compression Molding

Compression Molding