Top refurbished Tire Curing Press Service Provider in Chennai

Top refurbished Tire Curing Press Service Provider in Chennai

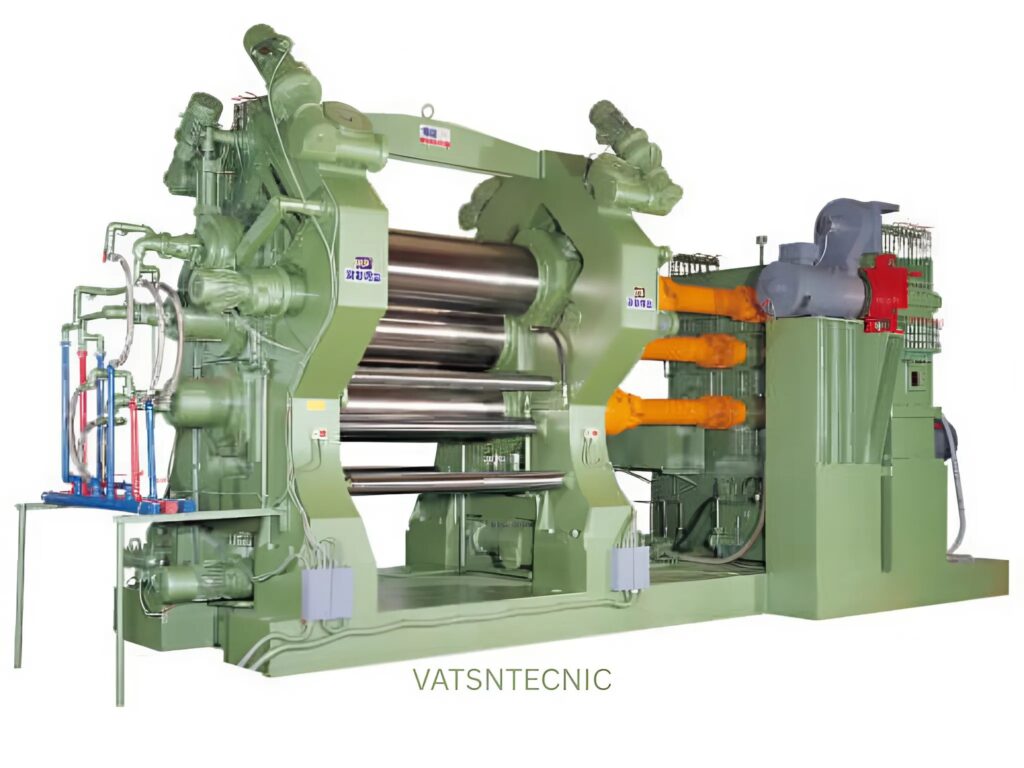

Are you seeking to place an order for a refurbished tire curing press setup in Chennai? You have clicked on the right link. A tire curing press, also referred to as a vulcanizing machine for tires, is anntial piece of equipment in the tire manufacturing process. A tire-curing press forms and hardens raw tires with heat and pressure, resulting in a solid product ready for the roads.

In this blog, you’ll learn the key benefits of installing a tire curing machine, how tire curing works, available government support schemes, ideal industrial locations in Chennai, and why VatsnTecnic is your best partner for both new and used tire vulcanizing machinery.

Key Advantages of Installing a Tire Curing Press Setup in Chennai

Starting a tire vulcanizing press unit brings long-term industrial benefits. Whether you’re a startup or scaling up, this machinery unlocks high value.

1. Better Tire Strength and Durability

- The curing process makes tires resistant to wear and pressure. It helps produce high-quality tires fit for highways and rugged terrain.

2. Streamlined Production Line

- With a tire curing press, your tire production becomes faster and more consistent. It helps maintain product standards.

3. Low Maintenance, High Output

- Most modern curing presses need minimal maintenance. They save both labor and machine downtime.

4. High Return on Investment (ROI)

- Tire curing machines offer steady profits. Their cost is quickly recovered through regular tire manufacturing.

Understanding the Tire Vulcanization Process: From Green Tire to Final Product

Let’s briefly look at how the tire curing process works in a factory.

1.Start with a Green Tire.

- A green tire is an uncured rubber casing assembled from different components.

2.Place in the curing press.

- The green tire goes into a curing mold cavity inside the tire press. The mold shapes the tread pattern.

3.Heat and Pressure Application

- The press applies heat (around 170°C) and hydraulic pressure. This changes the tire’s structure through vulcanization.

4.Final Finish

- After the time elapses, the cured tire is taken out. It is durable, elastic, and ready for vehicle use.

This process ensures every tire is viable for road use, there is reduced fuel usage, and it will last longer.

Available Government Support for Tire Vulcanizing Setup in Chennai

If you’re setting up a tire-curing press unit in Chennai, several government schemes can ease your investment burden.

1.MSME Subsidies and Assistance

- The Tamil Nadu Industrial Investment Corporation (TIIC) offers term loans toward the purchase of machinery. The loans provided to entrepreneurs are at low-interest rates for plant and machinery.

2.Credit Linked Capital Subsidy Scheme (CLCSS)

- You can claim a 15% capital subsidy under CLCSS for technology upgradation. Tire curing machines qualify under approved equipment.

3.Single Window Clearance & TReDS

- Startups benefit from single-window approvals via MSME portals. Also, TReDS (Trade Receivables Discounting System) helps with working capital issues.

4.Tamil Nadu Startup & EV Policies

- If you’re building tires for electric vehicles, Tamil Nadu’s EV policy 2023 supports vendors with land, capital, and tax benefits.

Best Industrial Zones in Chennai for Setting Up Tire Curing Press Units

Planning your unit in the right industrial area gives access to logistics, workforce, and buyers.

1. SIDCO Industrial Estate, Ambattur

- Ideal for small- and medium-scale tire and rubber industries. It offers developed land and shed facilities.

2. Oragadam Industrial Corridor

- A hub for automotive and rubber industries. Close to major highways and OEMs.

3. Guindy Industrial Estate

- Well-connected and ideal for refurbished or compact tire curing setups. Has great proximity to Chennai Port.

4. Sriperumbudur Industrial Park

- Large-scale infrastructure and access to automotive supply chains. Best for export-focused manufacturers.

These zones offer easy power connections, skilled labor, and logistics support, making them perfect for tire curing press installation.

Choose VatsnTecnic for Buying Tire Curing Press – New & Used Machines

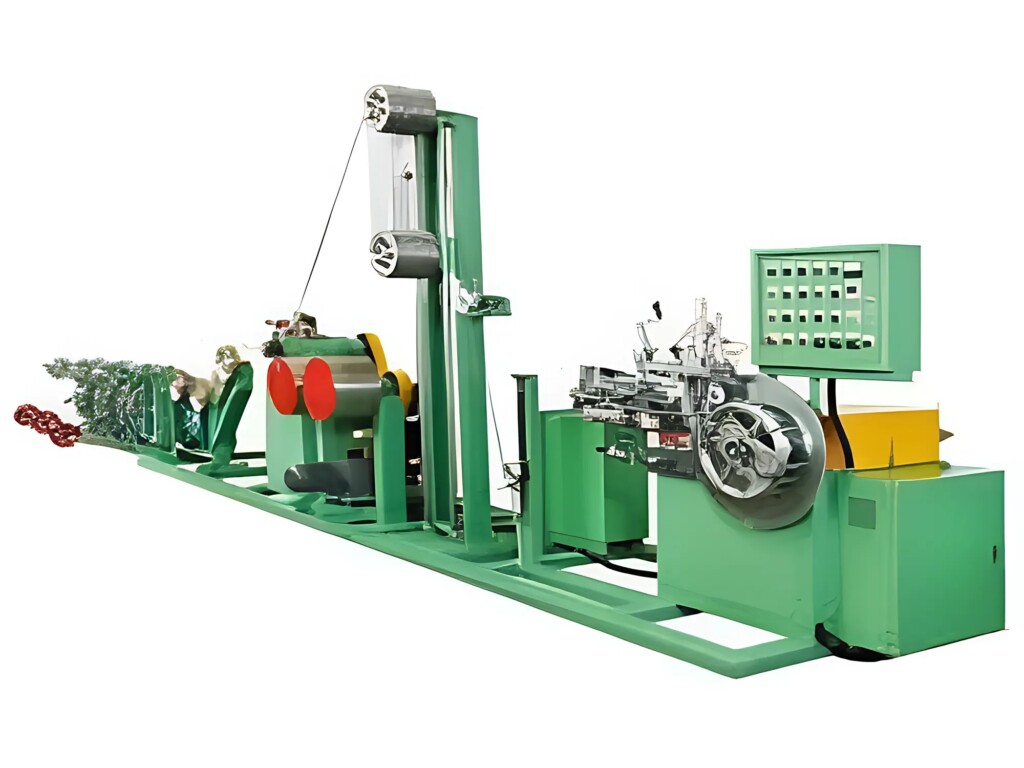

Looking for tyre curing press machines for sale in Chennai? VatsnTecnic is the name you can trust.

1. New Tyre Vulcanizing Press Machines

- VatsnTecnic offers advanced, energy-efficient tire curing presses. You can get custom sizes and automation levels to suit your needs.

2. Pre-Owned Machines with Full Support

- The company also provides fully serviced second-hand tire curing presses. These are tested, refurbished, and come with full setup assistance.

3. Installation and AMC Services

- From machine delivery to final setup, their team supports you every step. Annual maintenance contracts are also available.

4. Trusted in the Rubber Industry

- VatsnTecnic has years of experience in tire, conveyor belt, and rubber-related industries. They serve across Chennai, Tamil Nadu, and all over India.

Final Thoughts: Set Up Your Tire Curing Press with Confidence

Setting up a tire curing press in Chennai is a smart step for any industrial business. With high ROI, low maintenance, and growing demand for quality tires, now is the perfect time to invest.

Choose the right location, make use of government schemes, and trust the right partner.

VatsnTecnic is your one-stop solution for new and used tire curing press machines in Chennai. They provide expert installation, after-sales service, and reliable support to get your plant running smoothly.

FAQs – Tire Curing Press Setup in Chennai

Q1. What is the cost for the installation of a tire curing press in Chennai?

Basic setups start around ₹8–15 lakhs. Costs vary by size, automation, and brand.

Q2. Can I get a used tire curing press with full installation support?

Yes. VatsnTecnic offers both new and refurbished machines with setup and servicing.

Q3. Do you have to have very much space for a tire vulcanizing press?

Small units might need 1000–1500 sq. ft. Larger units more than 3000 sq. ft.

Q4. Are government subsidies available for tire manufacturing?

Yes. MSME and state government schemes offer loans, subsidies, and tax benefits.

Final Thoughts: Set Up Your Tyre Curing Press with Confidence

Setting up a tyre curing press in Chennai is a smart step for any industrial business. With high ROI, low maintenance, and growing demand for quality tires, now is the perfect time to invest.

Choose the right location, make use of government schemes, and trust the right partner.

VatsnTecnic is your one-stop solution for new and used tire curing press machines in Chennai. They provide expert installation, after-sales service, and reliable support to get your plant running smoothly.

For More Information Visit Here

Compression Molding

Compression Molding