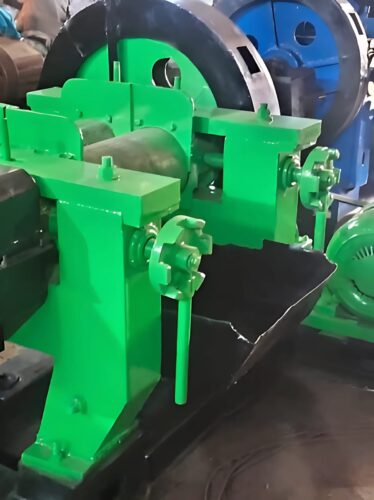

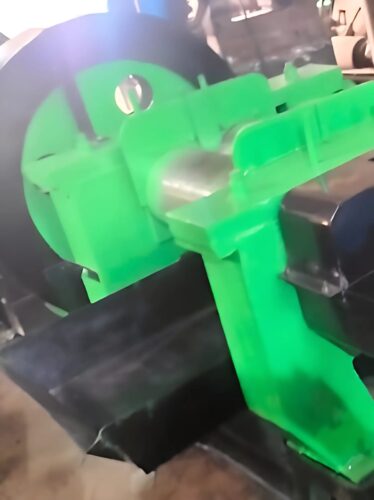

This is the ultimate solution for your rubber processing needs. It’s the 10 X 24 Rubber Mixing Mill, powered by a strong 20 HP motor. You may be in the rubber manufacturing industry. Or, you may need rubber processing for various applications. This machine offers unmatched efficiency and performance.

Uses of Rubber Mixing Mill –

- Rubber Compounding blends rubber with additives and fillers. This achieves precise blending to meet specific requirements. These requirements are for elasticity, durability, and other properties.

- Mastication breaks down raw rubber into smaller particles. This improves the consistency and uniformity of final products.

- Sheeting creates rubber sheets. The sheets have varying thickness. They are for further processing or product making.

- Calendering refines rubber sheets. It makes them to the desired thickness and surface finish. This enhances product quality and performance.

- Mix rubber compounds with pigments, oils, and other additives. This creates the desired color, texture, and properties for end products.

Why Choose Vatsn Tecnic for Your Rubber Mixing Mill Needs?

- Vatsn Tecnic specializes in high-quality, used rubber mixing mills. They ensure cost-effectiveness without sacrificing performance.

- We are in major Indian cities like Delhi, Mumbai, Chennai, and Bangalore. We are also in more cities. We ensure convenient access to reliable equipment and services wherever you are.

- Vatsn Tecnic offers more than equipment sales. They also offer a range of services. These include servicing, maintenance, and manpower provision. They also include annual maintenance contracts and consultancy for business expansion. With their support, you can make your rubber processing equipment work better. It will also last longer. You can do this while focusing on your core business goals.

Invest in the 10 X 24 Rubber Mixing Mill from Vatsn Tecnic today. You will experience unmatched performance, reliability, and support for all your rubber needs.

For more information Visit Here

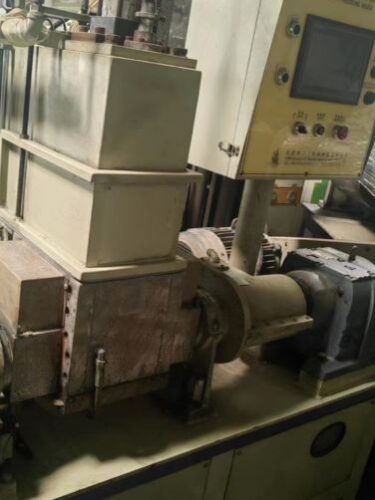

Compression Molding

Compression Molding