Rubber Refiner Mixing Mill in Madhya Pradesh

Rubber Refiner Mixing Mill in Madhya Pradesh – Industrial Manufacturing and Production System Guide

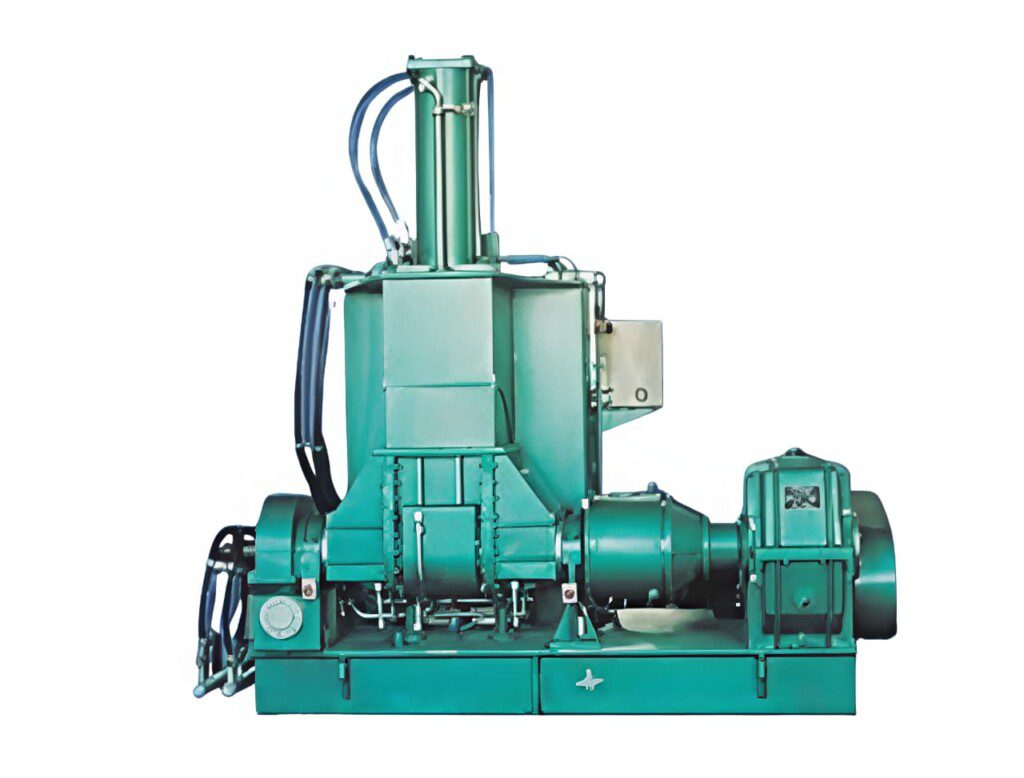

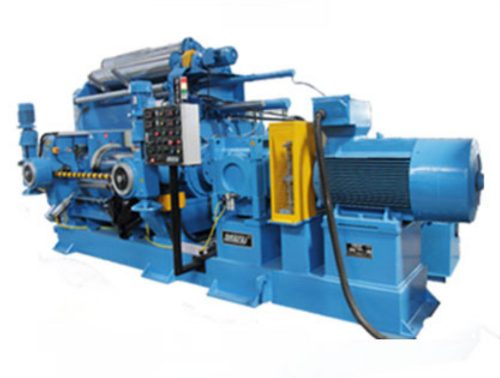

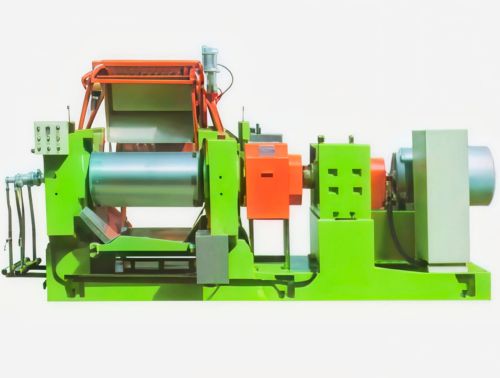

A Rubber Refiner Mixing Mill in Madhya Pradesh supports strong industrial growth because the state provides excellent infrastructure and skilled manpower. Moreover, manufacturers prefer Madhya Pradesh for rubber processing equipment due to its central location, which improves nationwide supply efficiency. In addition, a Rubber Refiner Mixing Mill production system ensures uniform rubber refinement. As a result, overall product quality improves consistently across rubber industries.

Rubber Refiner Mixing Mill Manufacturing Industry Growth in Madhya Pradesh

Benefits of Setting Up

- Madhya Pradesh offers affordable industrial land.

Moreover, power availability remains consistent.

Therefore, operating costs stay controlled. - A Rubber Refiner Mixing Mill manufacturing setup benefits from skilled technicians.

In addition, training institutes support workforce development.

As a result, production efficiency improves. - Transport connectivity strengthens logistics operations.

Moreover, rail and road networks reduce delivery delays.

Therefore, customer satisfaction increases. - Raw material availability supports smooth operations.

In addition, nearby rubber goods manufacturers create demand.

Government Scheme for Trusted Supplier

The government offers several supportive schemes.

Moreover, policies focus on machinery manufacturing growth.

Five key government support points include:

- Capital investment subsidies under MSME schemes.

- Moreover, GST reimbursement for eligible manufacturing units.

- Therefore, interest subsidies reduce financial burden.

- In addition, single-window clearance accelerates approvals.

- As a result, export promotion incentives support global sales.

These schemes strengthen Rubber Refiner Mixing Mill production development.

Major Industrial Areas for Rubber Refiner Mixing Mill Manufacturing Steps in Madhya Pradesh

Choosing the right location improves manufacturing efficiency.

Moreover, industrial clusters offer shared infrastructure.

Four major industrial areas include:

- Moreover, Mandideep supports engineering equipment production.

- Therefore, Indore provides skilled labor access.

- In addition, Dewas offers strong logistics connectivity.

- As a result, Bhopal supports technology-driven manufacturing.

These regions enhance steps.

Process and Production System Overview

- The manufacturing process follows structured stages.

Moreover, precision engineering ensures consistent output. - First, raw steel selection ensures durability.

Then, machining creates accurate roller dimensions.

Moreover, heat treatment improves roller strength. - Assembly integrates gearboxes and motors.

In addition, electrical systems ensure smooth control.

Therefore, final testing validates performance standards.

Each stage supports Rubber Refiner Mixing Mill production system development.

Quality Standards in Manufacturing Process

- Quality control ensures reliable machine performance.

Moreover, vibration testing checks operational stability.

Therefore, load testing confirms production capacity. - Surface finish inspection improves rubber processing quality.

In addition, safety features meet industrial compliance.

As a result, customer trust increases significantly.

Why Choose Vatsntecnic

- Vatsntecnic offers industry-focused manufacturing solutions.

Moreover, the company uses advanced engineering practices.

Therefore, machine durability remains high. - Customized designs meet specific production needs.

In addition, energy-efficient systems reduce operating costs.

As a result, buyers achieve better profitability. - Vatsntecnic ensures timely project delivery.

Moreover, after-sales support strengthens long-term relationships.

Manufacturing Technology Used by Vatsntecnic

- Vatsntecnic integrates modern CAD-based design systems.

Moreover, precision CNC machining improves component accuracy.

Therefore, machines deliver consistent rubber refinement. - Automation features enhance operator safety.

In addition, smart control panels improve usability.

As a result, productivity increases across shifts.

Future Scope

Ongoing demand from industry is evidenced in the continuing and increasing export of rubber products, which represents an opportunity for suppliers of equipment to experience substantial growth. The government has also implemented policies that encourage now and in the future increased investment in Madhya Pradesh. Developing infrastructure also supports further growth of the manufacturing industry, thereby ensuring that Madhya Pradesh is ideally placed to support ongoing industrial investment.

Conclusion

A rubber refining manufacturing unit in Madhya Pradesh offers long-term industrial benefits because strong policies and robust infrastructure support continuous growth. Moreover, this environment helps manufacturers achieve sustainable success. Choosing the right partner ensures reliable production systems, while quality-focused manufacturing improves market reputation. As a result, Vatsntecnic stands as a trusted name for advanced rubber machinery manufacturing and production systems in Madhya Pradesh.

For more information Visit Here

Compression Molding

Compression Molding