New Rubber Hot Air Rotocure Exporter in Sikkim

New Rubber Hot Air Rotocure Exporter in Sikkim | Industrial System Production Line

A new Rubber Hot Air Rotocure Exporter in Sikkim supports modern rubber curing industries. Moreover, the region enables a stable production process with controlled thermal environments. Therefore, manufacturers trust exporters who understand industrial manufacturing steps deeply. In addition, focused production system development ensures consistent curing quality. As a result, equipment production units deliver reliable performance across every industrial system production line.

Benefits of a Reliable Production Process in Sikkim | Industrial Manufacturing Steps

A reliable production process improves rubber curing accuracy for long-term usage. Moreover, industrial manufacturing steps remain controlled under varied operating conditions. Therefore, production system development supports uniform heat circulation. In addition, the machine-making process reduces surface defects. As a result, equipment production units achieve consistent output on the industrial system production line. Moreover, energy efficiency improves across the production process. Therefore, manufacturers gain predictable operational results.

Government Scheme for Setting Up a Trusted Supplier | Production System Development

Government schemes encourage production system development for rubber machinery exporters. Moreover, policy frameworks support advanced machine-making process adoption. Therefore, new exporters receive confidence for equipment production units expansion. In addition, industrial development support reduces initial capital pressure. As a result, the industrial system production line grows sustainably in Sikkim’s manufacturing ecosystem.

Major Industrial Areas for Setting Up Rubber Hot Air Rotocure | Industrial System Production Line

Sikkim offers structured industrial zones suitable for an industrial system production line. Moreover, these zones support smooth industrial manufacturing steps execution. Therefore, exporters benefit from reliable logistics connectivity. In addition, production system development aligns with regional infrastructure planning. As a result, equipment production units operate efficiently within approved industrial areas.

How Industrial Systems Are Made | Rubber Hot Air Rotocure Step-by-Step Manufacturing Process Using Production Process

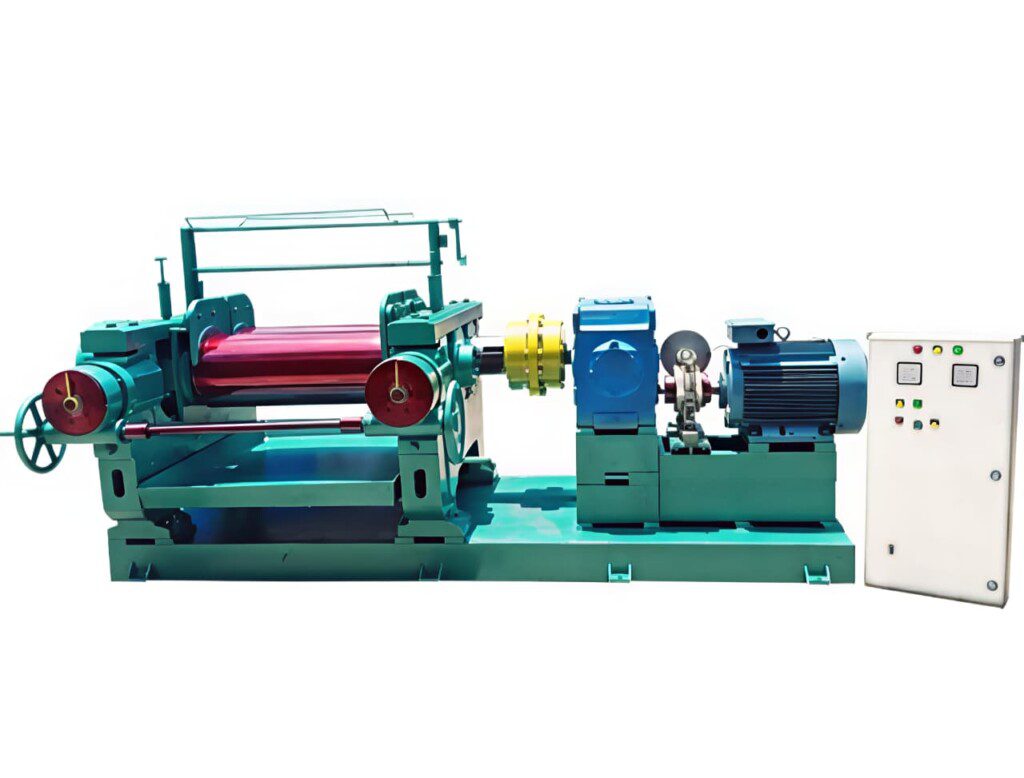

Industrial systems follow a disciplined production process for hot air rotocure technology. Moreover, planning starts with production system development and airflow design. Therefore, engineers define industrial manufacturing steps clearly. In addition, fabrication follows a precise machine-making process. As a result, equipment production units integrate seamlessly into the industrial system production line.

Why Choose VatsnTecnic? | Industrial Manufacturing Steps & Machine-Making Process

VatsnTecnic delivers expertise across industrial manufacturing steps for rubber curing machinery. Moreover, the company focuses on a stable production process design. Therefore, clients receive dependable production system development support. In addition, skilled teams manage the complete machine-making process. As a result, equipment production units maintain reliability throughout the industrial system production line.

Sikkim Government Schemes | Equipment Production Units & Production Process

Moreover, capital subsidy schemes support equipment production units

Therefore, industrial incentives strengthen the production process

In addition, technology assistance improves machine-making process adoption

As a result, industrial manufacturing steps become cost efficient

Moreover, infrastructure support enhances the industrial system production line

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For More Information Visit Here

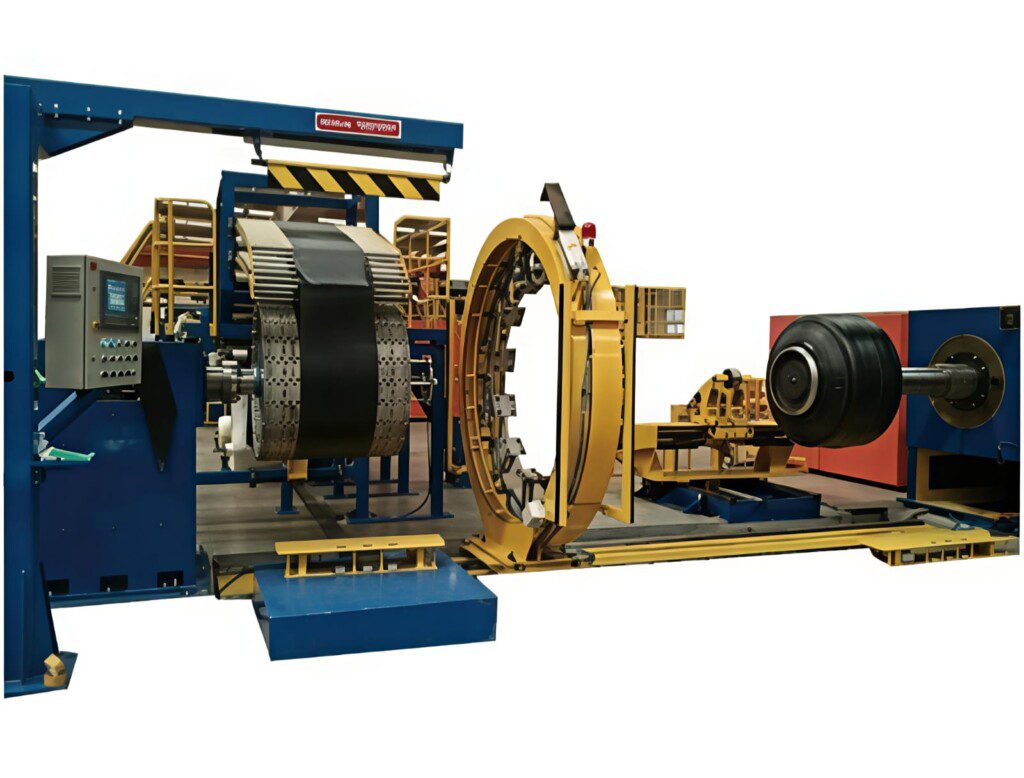

Compression Molding

Compression Molding