Vatsn-Tecnic has been a name of excellence in the field of the Sale/Purchase of Old/secondhand/Refurbished/Reconditioned Rubber processing Machinery for more than 30 years. Our company offers new and used rubber processing machinery from various countries, including China, Germany, the USA, the UK, and Russia. We take pride in providing premium quality products with the latest technology at reasonable prices. Our business has expanded globally and we are committed to offering our valued customers high-quality machinery.

Protocols To improve the overall customer experience, it is essential to provide excellent customer service not only before but also after a sale has been made. After conducting a thorough review, we have corrected all spelling, grammar, and punctuation errors in our communications.

Over the years, we have installed more than 1,000 units of rubber processing machinery. Different industries like tread rubber manufacturing use these machines. They are also used for making micro-cellular sheets and cycle tires. Additionally, they find application in automotive tubes, conveyor belts, and vee belts. Hawaii chappals and footwear use them in production. Rubber plants use them for making injection bottle caps. Our machinery has been successful in meeting the requirements of these industries.

premium quality Old/Second hand/Refurbished/Reconditioned Rubber processing Machinery for Sale in India.

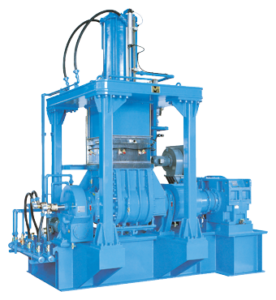

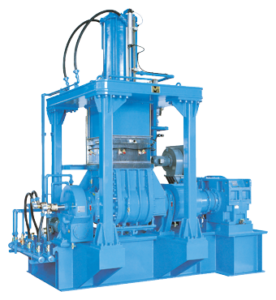

Our Old/Second Rubber Processing machinery is available in-house for sale in cities like Delhi, Mumbai, Chennai, and Kottayam. Today we will talk about the details of the Rubber Dispersion Kneader, its uses, and spare parts.

Rubber Dispersion Kneader Uses-

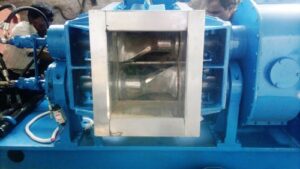

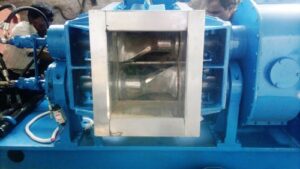

The machine consists of a mixing chamber fitted with high-grade steel rotary blades. The mixing of raw materials occurs in this chamber. Let me know if you need me to change anything else.

The mixing chamber has a pressure lid that controls material pressure. They control the pressure lid. The lid helps maintain material pressure while mixing.

If you frequently change the color of compounds, you’ll find that cleaning this machine is a breeze.

These machines are simple to work and their varied applications embody Natural Rubber, IIR, SBR, CR, EPDM, element Rubber, and synthetic rubber. Rubber Tires, Packing Gaskets, Hose, Belts, Shoe Sole, Sponges, electrical Wire Covering, Casters, Golf Balls, Oil Seal, Weather Strips, Water Proof Sheet, EVA, Thread Compound Battery Containers, Oil seal, Body seal, Gasket, Belt, Hose, Tube for cars Rubber for electrical wires Conveyor Belts & Power transmission belts Rubberized Rolls Rubber primarily based product like Plug, Cap, Glove, Dental for Medical line equipment sort of a rubber ball & Other Plastic Compounds.

Vatsn-Tecnic has been providing premium quality Old/Second hand/Refurbished/Reconditioned Rubber Dispersion Kneader for Sale in India for years now. Our Old/Second Rubber Dispersion Kneaders are available in-house for sale in cities like Delhi, Mumbai, Chennai, and Kottayam.

Dispersion Kneader Mixing Chamber-

1. Usually, the Dispersion Kneader mixing Chamber Shape is “W”: The mixing chamber is made of Alloy steel which is duly polished and hard chrome plated, Jacketed (both longitudinal & transverse) for steam heating & water cooling, capable of titling to 130 degrees (hydraulic tilt) for easy discharge & cleaning.

2. Earlier Rubber dispersion Kneaders feeding and discharge were done from the front side of the mixing chamber: Now, the Dispersion Kneaders feeding is done from the rear side and discharged to the front side, which allows for better automation and efficiency of the Rubber Dispersion Kneader.

3. About Rubber Dispersion Kneader Chamber Dust Seal and Housing: The Housing of Dispersion Kneader comprises heavy-duty antifriction spherical roller bearings with a specially designed seal for protection.

Dispersionamber Tilting-

1. Worm gear System: For tilting chamber OR Breakage of the screw and nuts.

2. Hydraulic Tiling: Zero maintenance compared to geared designs Enhancing the life of the equipment with better mixing and Trouble-free working.

Floating Weight (Pressure Lid)-

1. Single-piece alloy steel casting:

- Withstand maximum life and maintain side-to-side.

- Side-to-side clearance.

- Prevent leakage of ingredients.

2. Wider Surface area: It allows the ingredients to move & turn in the chamber freely.

Dispersion Kneader Rotors-

1. Two wing Tangential rotors: Facilitate different speeds through connection gear Move Rubber material from one portion to another.

2. Four Wing Tangential Rotors:

- distributive & dispersive Mixing.

- Homogeneous & masticate material processing.

- Greater Productivity.

Automation Control-

1. Push button Star Delta starting system: Consisting Switchgears and controls.

2. Electric Control Panel: Equipped with safety features like volt meter, amp meter, temperature Indicator, controllers, contractors, time buzzer, emergency switch, etc.

Gear Box-

1. Type: Hardened and Ground Helical reduction gearbox.

2. Use A suitable safety fall.

3. Noise: Minimum Noise level.

Compression Molding

Compression Molding

Hi I want to buy new machine 110l please give me sugetion