Reconditioned Swing Arm Cutting Press Dealer in Chennai

Reconditioned Swing Arm Cutting Press Dealer in Chennai – Your Ultimate Guide

Setting up a reconditioned swing arm cutting press in Chennai is a smart move for businesses in the leather, footwear, and fabric industries. These machines are cost-effective and offer precision cutting, making them perfect for startups or expanding workshops.

In this blog, we’ll explore the core benefits, government support, best industrial zones, and why VatsnTecnic is the most trusted dealer for new and used swing arm cutting machines.

Why Invest in a Reconditioned Swing Arm Cutting Machine?

A reconditioned swing arm cutting press is reliable and affordable. It delivers performance close to new machines at lower costs.

Key benefits of setting up a used swing arm cutting press:

- Reduced Cost of Investment: Reconditioned machines can be anywhere from 40 to 60% less expensive than new machines.

- Fast Return on Investment: You are saving more money every day you run your machine, and you can quickly recoup the cost of the machine with daily use.

- Strong Design: Good-quality machines have strong frames and last for many years of use.

- Less Power Consumption: Operates on less electricity than other methods for cutting.

- Less Maintenance: Parts are available and inexpensive.

- Multiple Use Application: Can be used for leather, rubber, fabrics, foam, and plastic sheets.

- Space Efficient: Very suitable for small shops or operations with limited space.

- Precision Cutting: High levels of accurate and consistent cutting are needed for mass production.

- Easier Operation: Less technical skill required for operation; just basic hydraulic functions.

- Environmental Support: When you reuse machines, this allows for more sustainable methods of operation.

Purpose of a Hydraulic Swing Arm Cutting Machine

Hydraulic swing arm cutting machines are used for punching and cutting soft to semi-rigid materials.

Common uses include

- Cutting leather for shoe uppers and handbags

- Punching foam, rubber sheets, and synthetic fabrics

- Die-cutting plastic, cork, and paperboard materials

This machine works with cutting dies (tools) and ensures uniform pressure across the cutting surface.

What is an Automatic Fabric Cutting Machine?

An automatic fabric cutting machine is a computerized system for high-speed textile cutting.

Features of automatic fabric cutters:

- Operated by CAD files or digital templates

- Ideal for bulk textile or garment production

- Offers zero-waste cutting with better material utilization

- Speeds up the cutting with minimal human error.

They differ from swing arm presses, which are manual or semi-automatic. Yet, both serve essential roles in manufacturing.

Government Schemes That Support Swing Arm Cutting Setup in Chennai

Many schemes exist to support MSMEs and manufacturing setups in Tamil Nadu and Chennai.

Here are some key subsidies and schemes:

- MSME Subsidies: The Ministry of MSME offers capital subsidies of up to 25% for machinery under the Credit Linked Capital Subsidy Scheme (CLCSS).

- Single Window Clearance: Tamil Nadu offers faster setup through an online business portal for manufacturing units.

- Startup India Benefits: First-time entrepreneurs may get income tax rebates, registration help, and funding.

- SIDBI Loans: SIDBI supports new units with machinery loans and soft funding at low interest.

- TIIC Machinery Loan: Tamil Nadu Industrial Investment Corporation offers term loans for machine purchases in manufacturing.

- Power Tariff Subsidy: Units in notified industrial areas can get discounted electricity rates.

Best Industrial Zones in Chennai for Setting Up Swing Arm Cutting Units

Chennai has several well-developed industrial belts that support small and medium manufacturing setups.

Top industrial zones for machine setup:

- Guindy Industrial Estate: Accessible to the city, suitable for footwear and leather startups.

- Ambattur Industrial Area: A large workforce, transport accessibility, and rental opportunities.

- Thirumudivakkam Industrial Estate: Typical preference for small engineering and machinery businesses.

- Sriperumbudur Industrial Region: SEZ supported by the government and good for exports.

- Perungudi Industrial Estate: Near IT and small-scale units, good logistics.

- Padi SIDCO Industrial Estate: Strong vendor base and machine repair services nearby.

Each of these zones offers support infrastructure, power backup, skilled labor, and transport connectivity.

Why Choose VatsnTecnic for New and Used Swing Arm Cutting Presses?

When looking for a swing arm cutting machine for sale, the dealer’s credibility is crucial.

VatsnTecnic stands out for several reasons:

- Manufacturers in India Trust Us: From Chennai to Delhi and Mumbai, we service all major cities.

- Choose from a wide range of machines: refurbished, new machines, semi-automatic, or hydraulic swing arm presses.

- All machines are fully serviced and tested: all machines are serviced and tested before being delivered.

- Affordable Pricing: Our used swing arm cutting machines are competitively priced with quality assurance.

- After-Sales Support: Get help with AMC, machine servicing, and spare part availability.

- Buy or Sell Easily: We help factories upgrade by exchanging or buying used cutting machines.

Whether you’re starting a new business or expanding an old one, VatsnTecnic offers trusted machines that deliver performance and value.

Conclusion

A reconditioned swing arm cutting press in Chennai is a great investment for the leather, footwear, rubber, or packaging industries. With government support, low-cost machines, and prime industrial zones, your business setup becomes easier and more profitable.

To buy or sell a swing arm cutting machine in Chennai, trust VatsnTecnic—India’s reliable source for new and used cutting equipment. We help you save more and grow faster.

Frequently Asked Questions (FAQs)

Q1. What materials can I cut with a swing arm cutting press?

You can cut leather, foam, rubber sheets, synthetic textiles, cardboard, plastic, and felt materials.

Q2. Can I get a subsidy if I buy a used swing arm cutting press?

Subsidies usually apply to new machinery. However, loans or soft funding may still be available for factory setup.

Q3. Is it better to buy a new or reconditioned cutting machine?

If your budget is tight, a reconditioned press offers similar results with lower cost and quick ROI.

Q4. How long does a used hydraulic swing arm machine last?

If well-maintained, these machines can last 10–15 years. VatsnTecnic provides machines with tested durability.

For More Information Visit Here

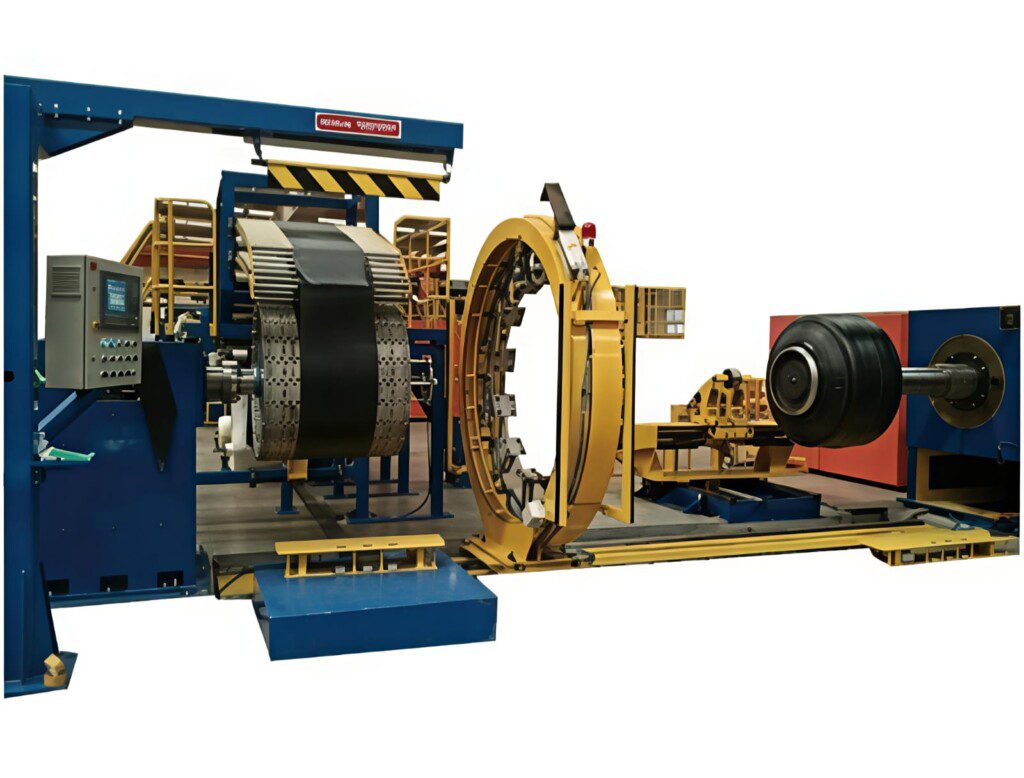

Compression Molding

Compression Molding