Buy | Sell Used Rubber Compound Mixing Mill 16 X 42 Motor 60 Hp

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

|

Overall dimension(mm)

|

L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

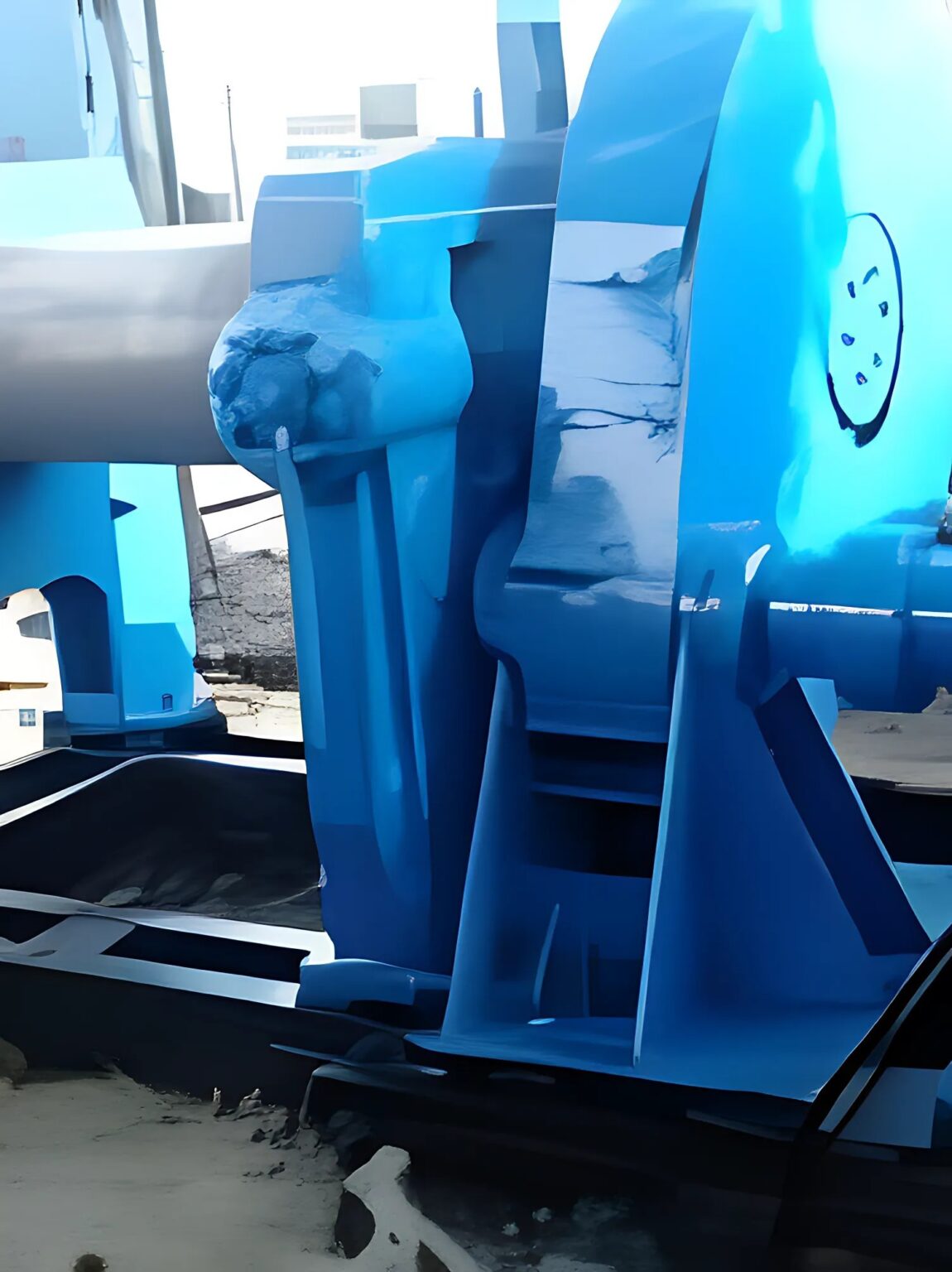

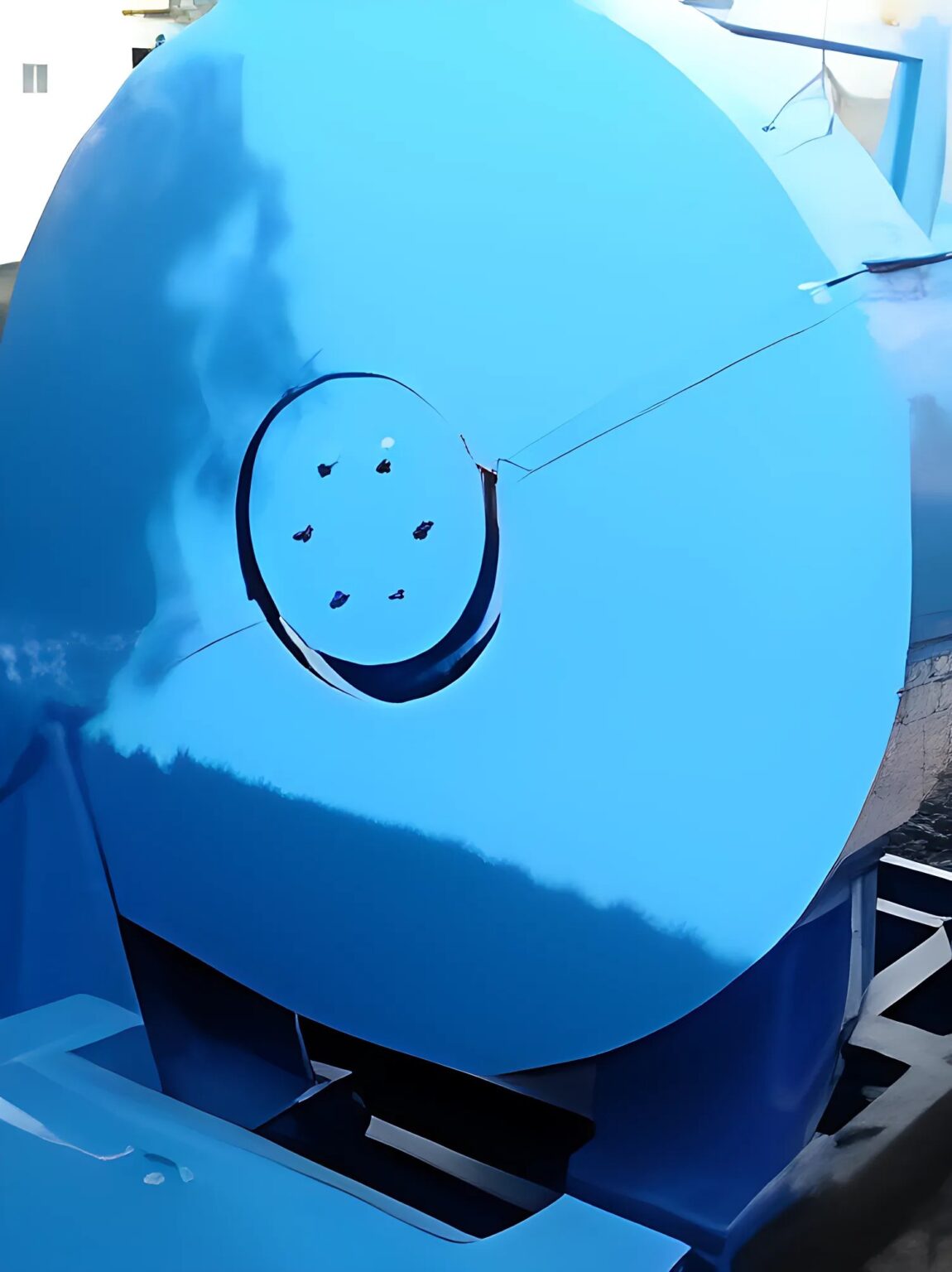

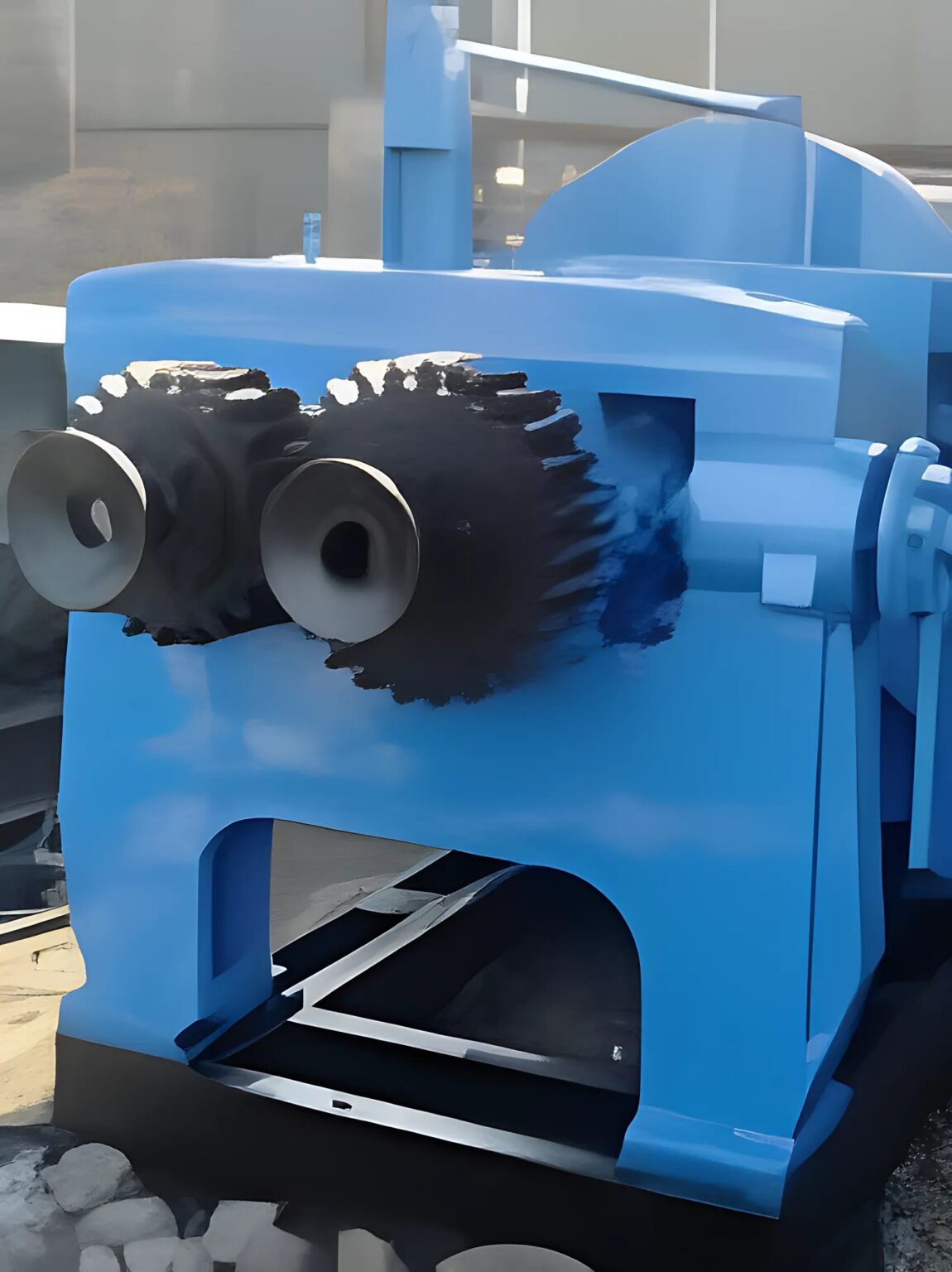

Introducing the ultimate solution for your rubber processing needs – the Used Rubber Compound Mixing Mill 16 X 42 Motor 60 HP, now available through Vatsn Tecnic! Designed to meet the demands of various industries, this mixing mill offers unparalleled performance and efficiency in rubber compounding.

Key Features –

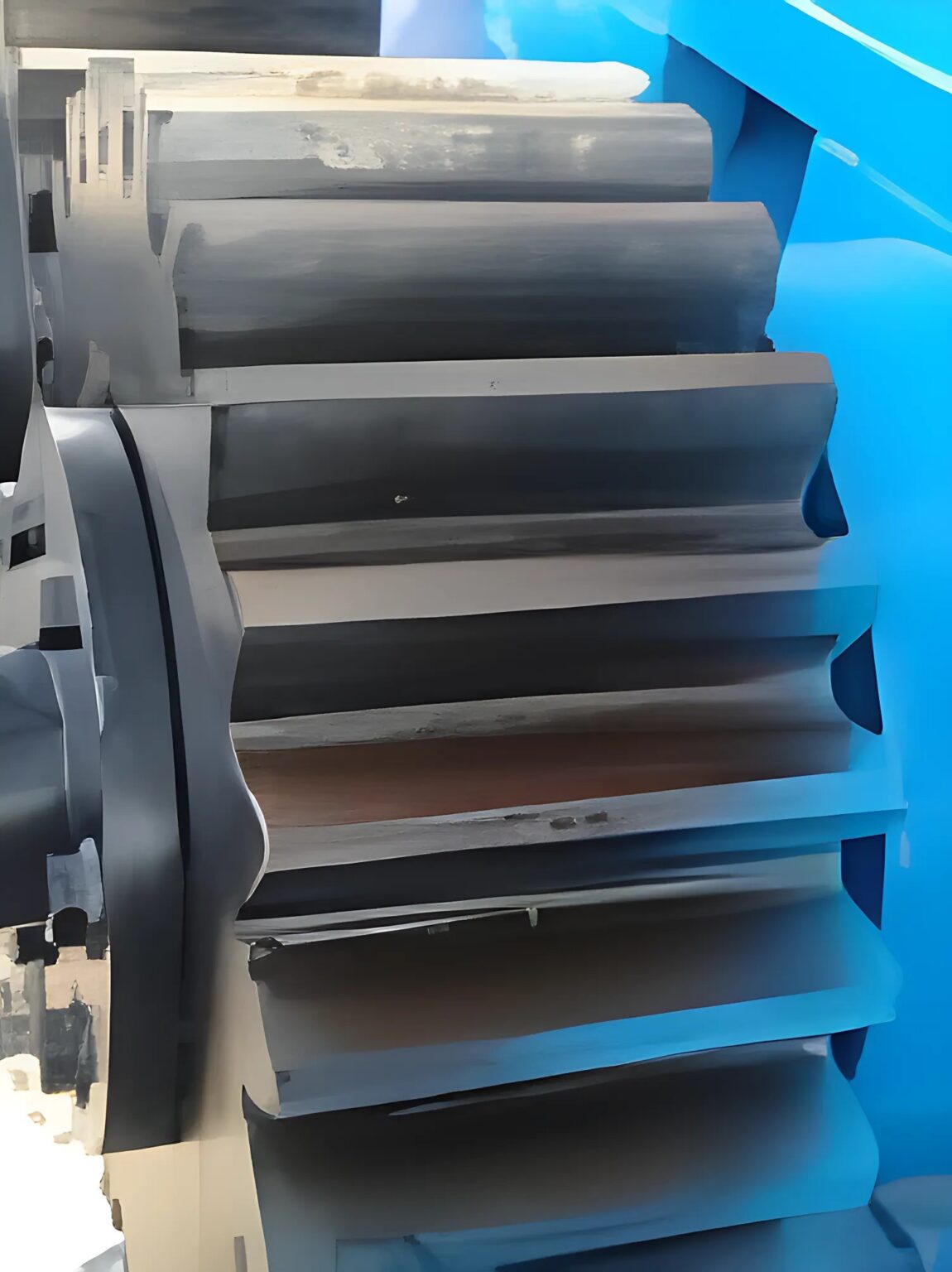

1. 16 X 42 Size: Ample space for efficient mixing of rubber compounds, ensuring uniformity and consistency.

2. Powerful 60 HP Motor: Drives the mixing process with precision and reliability, capable of handling various types of rubber compounds.

3. Durable Construction: Crafted from high-quality materials, built to withstand the rigors of continuous operation.

4. Secondhand Yet High-Quality: Rest assured, despite being secondhand, this mixing mill has been meticulously inspected and maintained to ensure optimal performance.

Uses of Rubber Compound Mixing Mill –

i) Rubber Processing: Ideal for mixing, blending, and kneading rubber compounds to achieve desired properties such as elasticity, strength, and durability.

ii) Tire Manufacturing: Essential equipment in the production of tires, ensuring uniform distribution of rubber compounds for consistent tire quality.

iii) Industrial Applications: Widely used in various industries including automotive, construction, and aerospace for manufacturing rubber products such as seals, gaskets, hoses, and more.

Why Choose Vatsn Tecnic?

Vatsn Tecnic stands out as the premier destination for secondhand rubber processing equipment in India. With a strong presence in major cities like Delhi, Mumbai, Chennai, Bangalore, and more, Vatsn Tecnic offers convenience and reliability to its customers. Additionally, Vatsn Tecnic provides comprehensive support services including:

i) Servicing: Expert maintenance and repair services to keep your equipment running smoothly.

ii) Manpower: Skilled technicians available for on-site assistance and troubleshooting.

iii) Annual Maintenance Contracts: Ensure the longevity and efficiency of your equipment with tailored maintenance plans.

iv) Consultancy: Expert guidance for business expansion and optimization of rubber processing operations.

For more information Visit Here

Compression Molding

Compression Molding