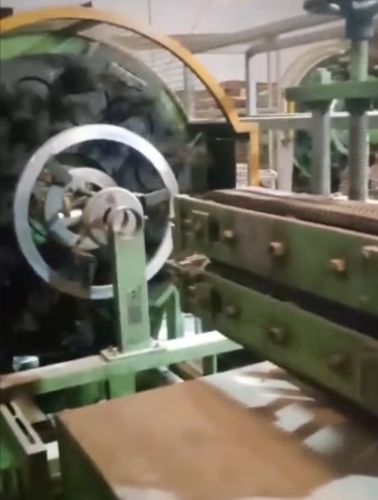

Rubber Hose Pipe Making Machinery

Manufacturing Process in Maharashtra | Industrial Production System Development

- Rubber hose pipe making machinery supports modern industrial infrastructure across India.

Moreover, Maharashtra plays a vital role in industrial system production line development.

The state offers strong logistics, skilled labor, and manufacturing ecosystems.

Therefore, manufacturers prefer Maharashtra for equipment production units. - Rubber hose pipe making machinery enables efficient fluid transfer solutions.

In addition, these machines serve automotive, agriculture, oil, and construction sectors.

The machine making process requires precision engineering and standardized systems.

Moreover, industrial manufacturing steps reduce waste and operational costs.

Manufacturers also adopt advanced production system development strategies.

Therefore, output capacity increases without compromising durability. - Maharashtra supports innovation-driven industrial growth.

In addition, government policies encourage industrial investments.

As a result, industrial system production lines expand rapidly.

Benefits of a Reliable Production Process in Maharashtra

- Strong industrial infrastructure supports smooth industrial manufacturing steps

- Skilled workforce improves machine making process efficiency

- Robust logistics ensure fast material movement

- Stable power supply enhances equipment production units

- Industrial clusters support production system development

- Favorable policies encourage industrial system production line growth

Government Scheme for Setting Up a Trusted Supplier of Rubber Dispersion Kneader Machines in Delhi

Delhi offers structured support for industrial machine manufacturers.

Moreover, government schemes help trusted suppliers grow sustainably.

- MSME schemes provide registration benefits and compliance support

- Capital subsidies reduce initial equipment investment burden

- Low-interest loan assistance improves production process scalability

- Technology upgrade schemes support advanced industrial manufacturing steps

- Industrial development programs enhance production system development

These schemes encourage reliable machine making process adoption.

Therefore, suppliers achieve long-term industrial stability.

Major Industrial Areas for Setting Up Manufacturing Units in Maharashtra

Maharashtra hosts several industrial hubs supporting equipment production units.

Moreover, these zones ensure smooth industrial system production line operations.

- Pune Industrial Region

- Aurangabad Industrial Belt

- Nashik Manufacturing Zone

- Nagpur MIHAN Area

- Mumbai–Thane Industrial Corridor

These regions support advanced production process planning.

As a result, manufacturers achieve faster industrial manufacturing steps.

How Industrial Systems Are Made | Step-by-Step Manufacturing Process

Rubber hose pipe making machinery follows a structured industrial approach.

Moreover, each stage supports consistent output quality.

Raw Material Selection

High-grade rubber compounds are selected first.

Therefore, material strength meets industrial standards.

Compound Mixing

Rubber compounds enter dispersion or mixing systems.

Moreover, uniform mixing supports product durability.

This stage defines the production process foundation.

Extrusion Process

Mixed rubber feeds into extrusion equipment.

Therefore, hoses achieve precise diameters and thickness.

Extrusion ensures smooth industrial manufacturing steps.

Reinforcement Layering

Textile or steel layers reinforce hose strength.

Moreover, pressure resistance improves significantly.

This step strengthens the industrial system production line.

Vulcanization

Hoses enter curing chambers for heat treatment.

As a result, rubber achieves elasticity and durability.

Vulcanization finalizes the machine making process quality.

Cutting and Finishing

Hoses are cut to standard lengths.

Moreover, surface finishing improves visual quality.

This stage supports professional equipment production units.

Testing and Quality Control

Each hose undergoes pressure and leakage tests.

Therefore, reliability meets industry requirements.

Testing ensures strong production system development outcomes.

Packaging and Dispatch

Finished hoses receive protective packaging.

Moreover, logistics planning ensures safe delivery.

This completes the industrial manufacturing steps.

Role of Automation in Rubber Hose Pipe Making Machinery

By utilizing automation within their factories, manufacturers are able to produce products faster and with greater precision than ever before. Furthermore, through the elimination of human errors associated with manual labour, manufacturers can achieve more consistent output. Modern manufacturing machinery has been designed to work with Programmable Logic Controllers (PLCs). These PLCs allow manufacturers to monitor various performance metrics of their production processes.

Automated manufacturing systems have also helped to reduce the costs of running a business. As a result, businesses that utilize automation have an advantage over their competitors.

Importance of Quality Standards in Equipment Production Units

- Quality standards ensure market acceptance.

Moreover, compliance builds customer trust.

Therefore, manufacturers follow ISO and industrial norms. - Standardization improves machine making process reliability.

In addition, maintenance requirements reduce.

This strengthens the industrial system production line.

Sustainability in Industrial Manufacturing Steps

Sustainable manufacturing reduces environmental impact across equipment production units.

Moreover, energy-efficient machines optimize the overall production process.

Therefore, production costs decrease over time.

Waste recycling supports responsible production process management.

In addition, sustainable materials enhance product lifecycle.

Efficient resource utilization improves industrial manufacturing steps.

As a result, operational efficiency increases across the industrial system production line.

This approach strengthens long-term production system development.

Market Demand for Rubber Hose Pipe Making Machinery

- Industrial expansion increases hose demand.

Moreover, agriculture and construction drive consumption.

Therefore, machinery demand grows steadily. - Export opportunities further support equipment production units.

In addition, customized solutions attract global buyers.

This boosts industrial system production line investments.

Why Choose VatsnTecnic? for Industrial Machine Manufacturing

VatsnTecnic delivers reliable industrial machinery solutions.

Moreover, the company focuses on precision engineering.

VatsnTecnic offers strong technical support.

Therefore, clients receive long-term operational assistance.

The company ensures scalable production system development.

In addition, machines support diverse industrial applications.

VatsnTecnic maintains consistent quality standards.

As a result, machine making process reliability remains high.

Years of industry experience strengthen customer confidence.

Moreover, project execution follows structured industrial manufacturing steps.

For advanced machinery and industrial manufacturing solutions, choose VatsnTecnic.

For more information Visit Here

You must be logged in to post a review.

Compression Molding

Compression Molding

Reviews

There are no reviews yet.