Buy | Sell Used Rubber Textile Fabric Conveyor Belt Production line 1600 X10000 mm

A rubber conveyor belt production line involves various processes to create durable and efficient conveyor belts used in industries for material transportation. The production line typically includes several key stages:

- Raw Material Preparation: The process begins with selecting high-quality raw materials such as natural rubber, synthetic rubber, and reinforcing materials like fabric or steel cords.

- Compounding: The selected raw materials are then mixed and compounded to create a homogeneous rubber compound. This process is crucial to achieving the desired properties such as strength, flexibility, and resistance.

- Calendering: The compounded rubber is passed through calenders to form sheets of the required thickness. Calendars help in shaping and smoothing the rubber.

- Fabrication: Layers of fabric or steel cords are added to provide reinforcement and enhance the strength of the conveyor belt. The number and arrangement of these layers depend on the desired characteristics of the final product.

- Vulcanization: The assembled conveyor belt goes through a vulcanization process, involving heat and pressure. This step cures the rubber, creating a robust and durable structure.

- Cutting and Finishing: Once vulcanized, the conveyor belt is cut to the desired width and length. Additional finishing processes may include applying coatings for specific functionalities, such as resistance to abrasion or chemicals.

- Quality Control: Throughout the production line, rigorous quality control measures are implemented to ensure that the conveyor belts meet industry standards and customer specifications.

Different types of rubber conveyor belts cater to various industrial needs. Common types include:

- Flat Belt: Suitable for horizontal conveyance.

- Incline or Decline Belt: Designed for transporting materials at an angle.

- Cleated Belt: Features cleats or partitions for elevating materials.

- Sidewall Belt: Ideal for vertical conveying with attached side walls.

- Steel Cord Belt: Reinforced with steel cords for heavy-duty applications.

- Heat-Resistant Belt: Designed to withstand high temperatures.

- Oil-Resistant Belt: Resistant to oil and grease.

Various machines contribute to the production of rubber conveyor belts, such as mixing mills, calenders, extruders, and vulcanizing presses. The selection of machinery depends on the type and specifications of the conveyor belt.

At Vatsn Tecnic, we specialize in refurbished rubber processing machinery, offering cost-effective and reliable solutions for the production of conveyor belts and other rubber products. Our refurbished machinery ensures high-quality output and efficiency in rubber processing operations.

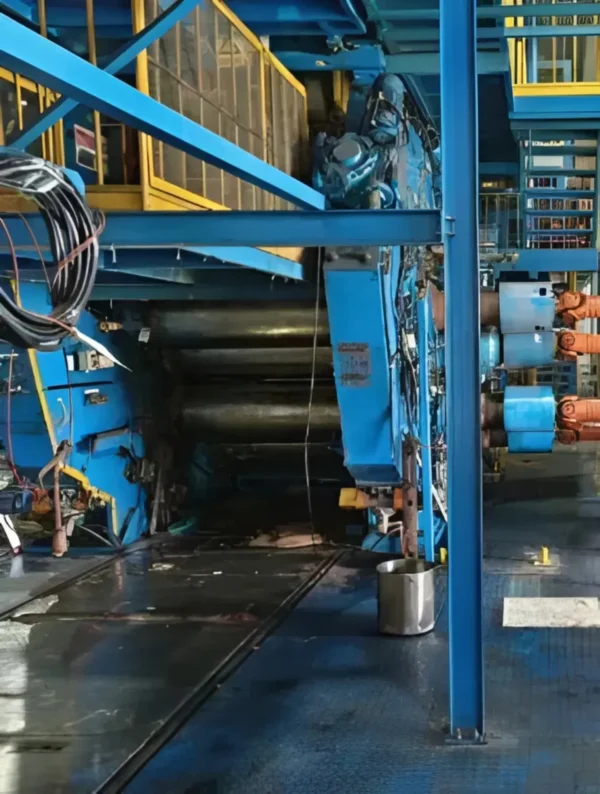

Introducing the premium quality, secondhand Rubber Textile Fabric Conveyor Belt Production line, sized at 1600 X 10000 mm, available exclusively through Vatsn Tecnic! Designed to meet the diverse needs of various industries, this production line offers exceptional performance and durability.

Product Features –

1. High-Quality Construction: Crafted from top-grade materials, our Rubber Textile Fabric Conveyor Belt Production line ensures longevity and reliability in your operations.

2. Optimized Size: With dimensions of 1600 X 10000 mm, this production line is ideal for handling a wide range of materials efficiently.

3. Versatile Applications: From manufacturing plants to warehouses, this conveyor belt production line is suitable for various industries such as mining, food processing, agriculture, and more.

4. Cost-Effective Solution: Investing in secondhand equipment doesn’t mean compromising on quality. Our production line offers exceptional value for money, helping you optimize your budget without sacrificing performance.

Uses of Rubber Textile Fabric Conveyor Belt Production Line –

i) Material Handling: Effortlessly transports materials across different stages of production with precision and ease.

ii) Assembly Line Operations: Streamline your assembly processes by integrating our conveyor belt production line, enhancing productivity and workflow efficiency.

iii) Packaging: Facilitate seamless packaging operations by conveying products swiftly and securely, minimizing downtime, and maximizing output.

Why Choose Vatsn Tecnic:

Vatsn Tecnic is your trusted partner in the procurement of used Rubber Textile Fabric Conveyor Belt Production lines. Here’s why we stand out:

1. Extensive Industry Experience: With years of expertise in the field, we understand the unique requirements of diverse industries, offering tailored solutions to meet your specific needs.

2. Nationwide Presence: Operating in major cities across India including Delhi, Mumbai, Chennai, Bangalore, and more, we ensure prompt and efficient service delivery wherever you are located.

3. Comprehensive Support: Beyond just selling equipment, we provide a range of services including servicing, maintenance, manpower assistance, annual maintenance contracts, and consultancy services for business expansion, ensuring the seamless operation of your production line.

4. Quality Assurance: Each product undergoes rigorous inspection to ensure it meets our high standards of quality and performance, giving you peace of mind with every purchase.

Upgrade your production capabilities with Vatsn Tecnic’s secondhand Rubber Textile Fabric Conveyor Belt Production line. Contact us today to explore how our solutions can elevate your business!

For more information Visit Here

Compression Molding

Compression Molding