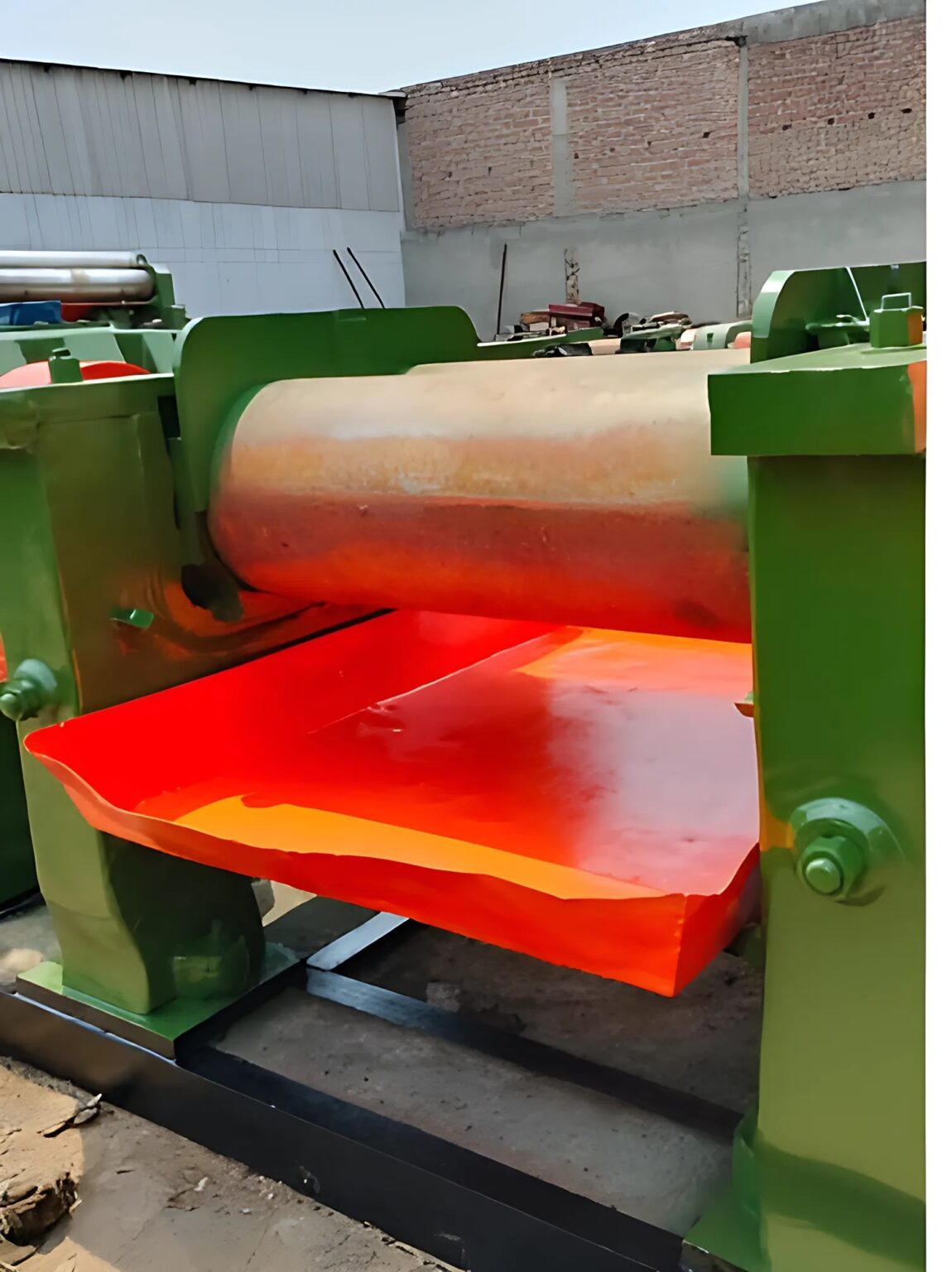

Buy | Sell Used Mixing Mill With Gearbox 16 X 42 Motor HP 60

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

Overall dimension(mm) | L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

Unlock the potential of your rubber and plastic manufacturing with our high-quality used Mixing Mill With Gearbox 16 X 42, powered by a robust 60 HP motor. This versatile and reliable equipment is ideal for a variety of industrial applications, ensuring efficient and consistent mixing of raw materials. Here’s why our mixing mill stands out:

Key Features –

i) Durable Build: Engineered to withstand the rigors of continuous operation.

ii) Efficient Performance: The powerful 60 HP motor ensures high throughput and uniform mixing.

iii) Precision Control: Equipped with a gearbox for precise speed and torque control.

iv) Large Capacity: The 16 X 42 size is perfect for handling substantial batches, and optimizing production efficiency.

v) Cost-Effective: A used mixing mill offers significant savings without compromising on performance and reliability.

Uses of Mixing Mill With Gearbox –

i) Rubber Mixing: Ideal for mixing raw rubber with other additives to achieve desired material properties.

ii) Plastic Compounding: Efficiently blends polymers with additives, fillers, and colorants.

iii) Silicone Processing: Mixes silicone rubber and additives for various industrial applications.

iv) Material Conditioning: Prepares materials for further processing steps such as extrusion or molding.

v) Recycling Operations: Processes reclaimed rubber or plastic materials for reuse in manufacturing.

Why Choose Vatsn Tecnic?

i) Expertise in Secondhand Equipment: Specializing in the sale and purchase of used mixing mills, ensuring you get the best quality and value.

ii) Nationwide Service: Operating in major cities across India including Delhi, Mumbai, Chennai, and Bangalore.

iii) Comprehensive Support: Providing servicing, maintenance, manpower, annual maintenance contracts, and consultancy to ensure your equipment runs smoothly and efficiently.

iv) Customer-Centric Approach: Dedicated to meeting your specific needs with tailored solutions and professional guidance.

For more information Visit Here

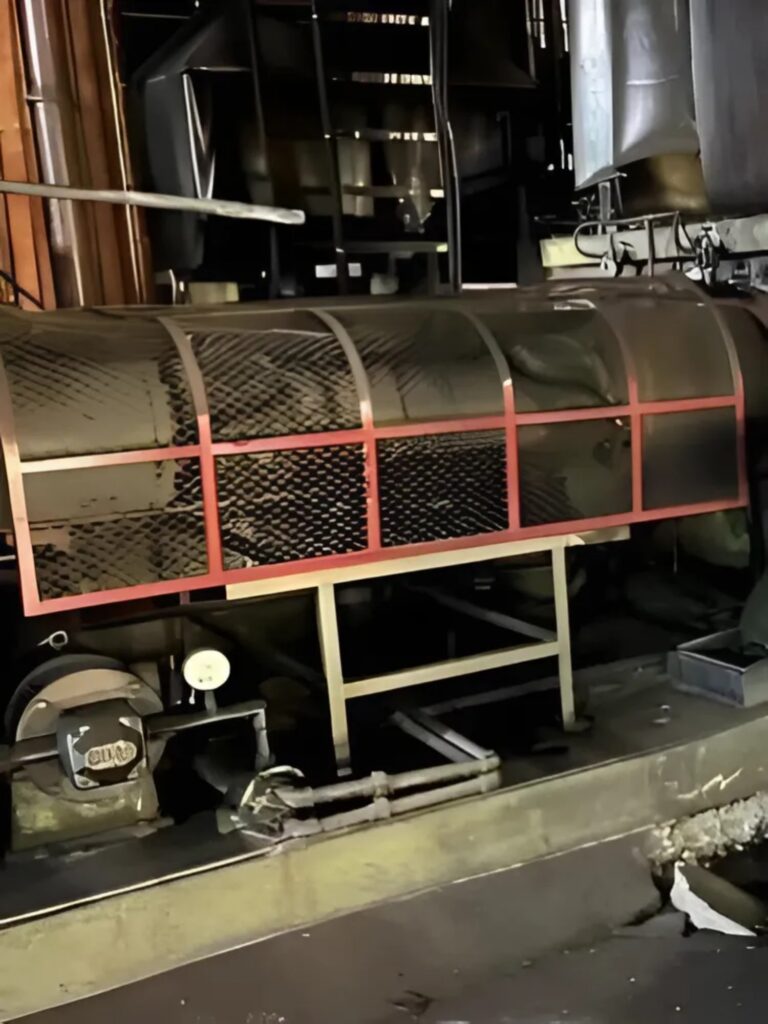

Compression Molding

Compression Molding