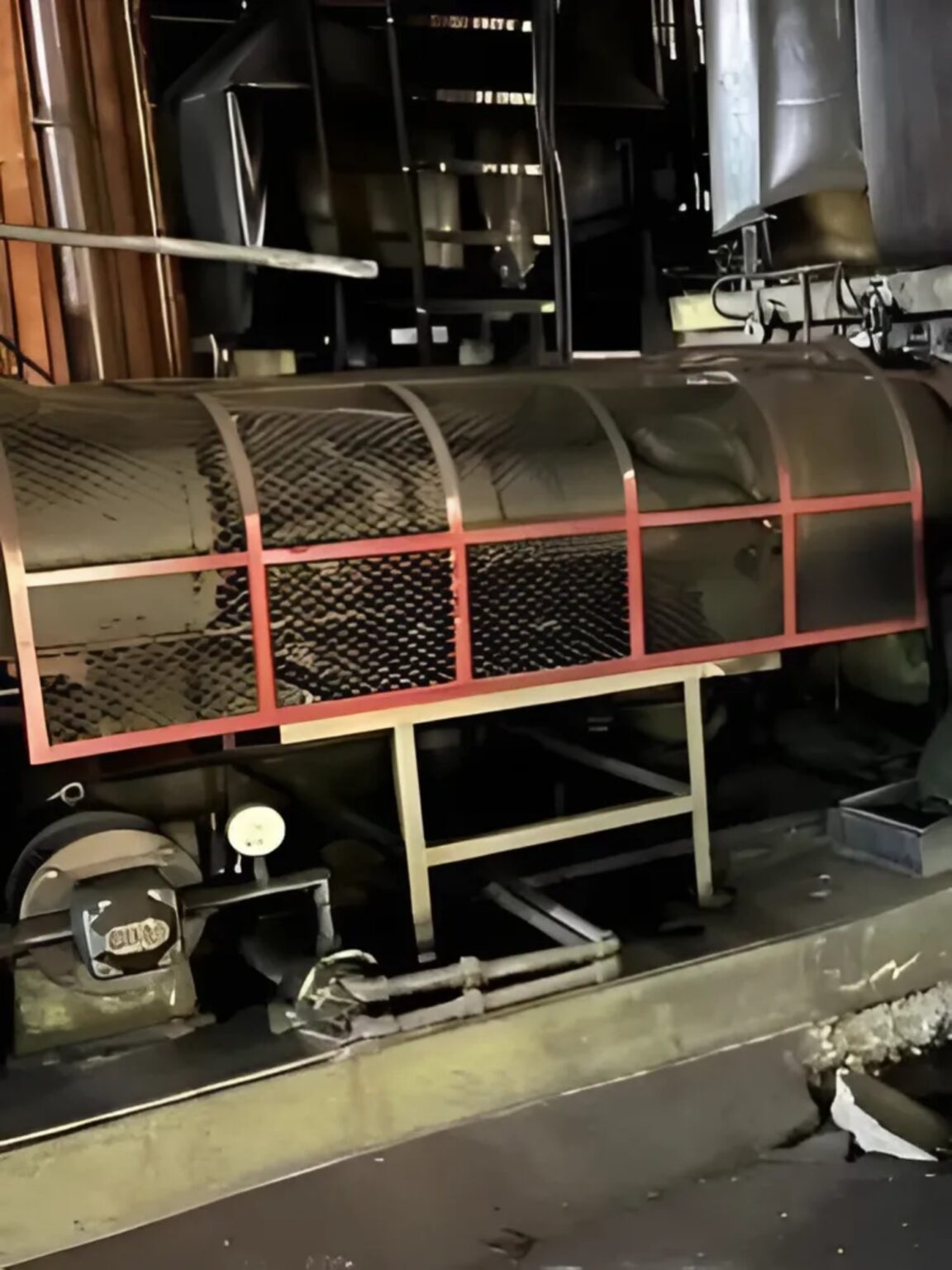

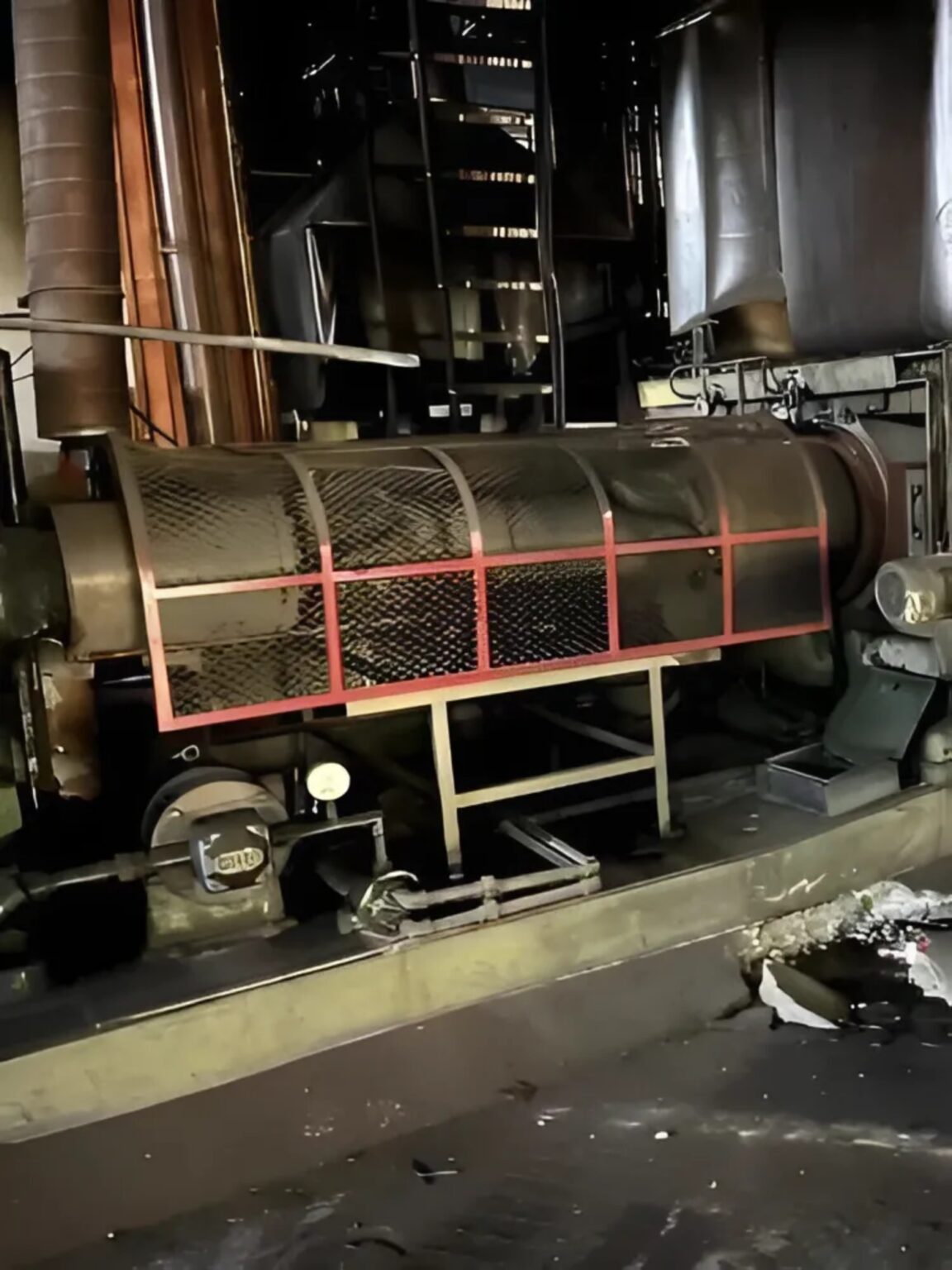

Buy | Sell Used High Production Rubber Mixing Mill 26 X 84

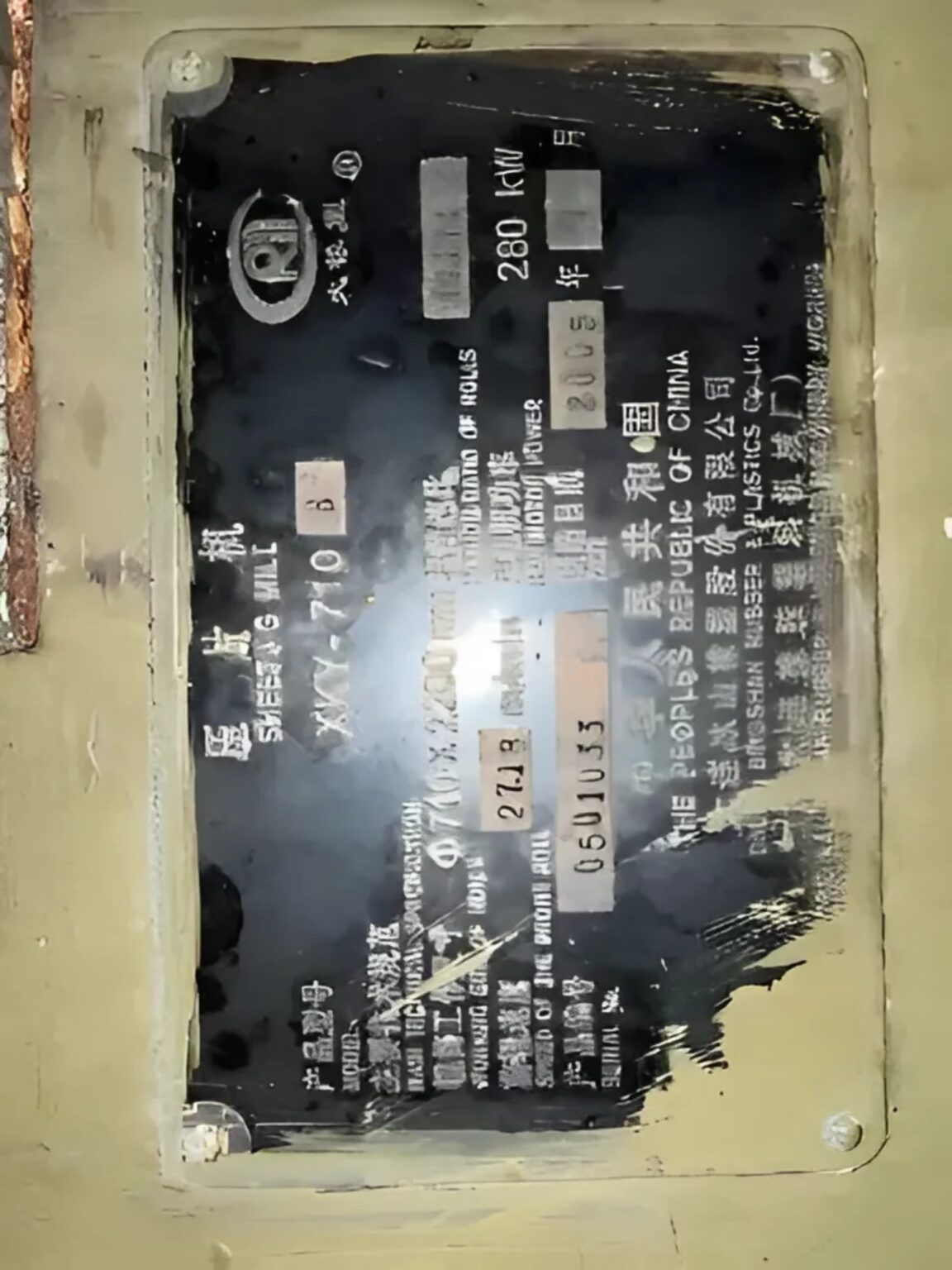

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

|

Overall dimension(mm)

|

L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

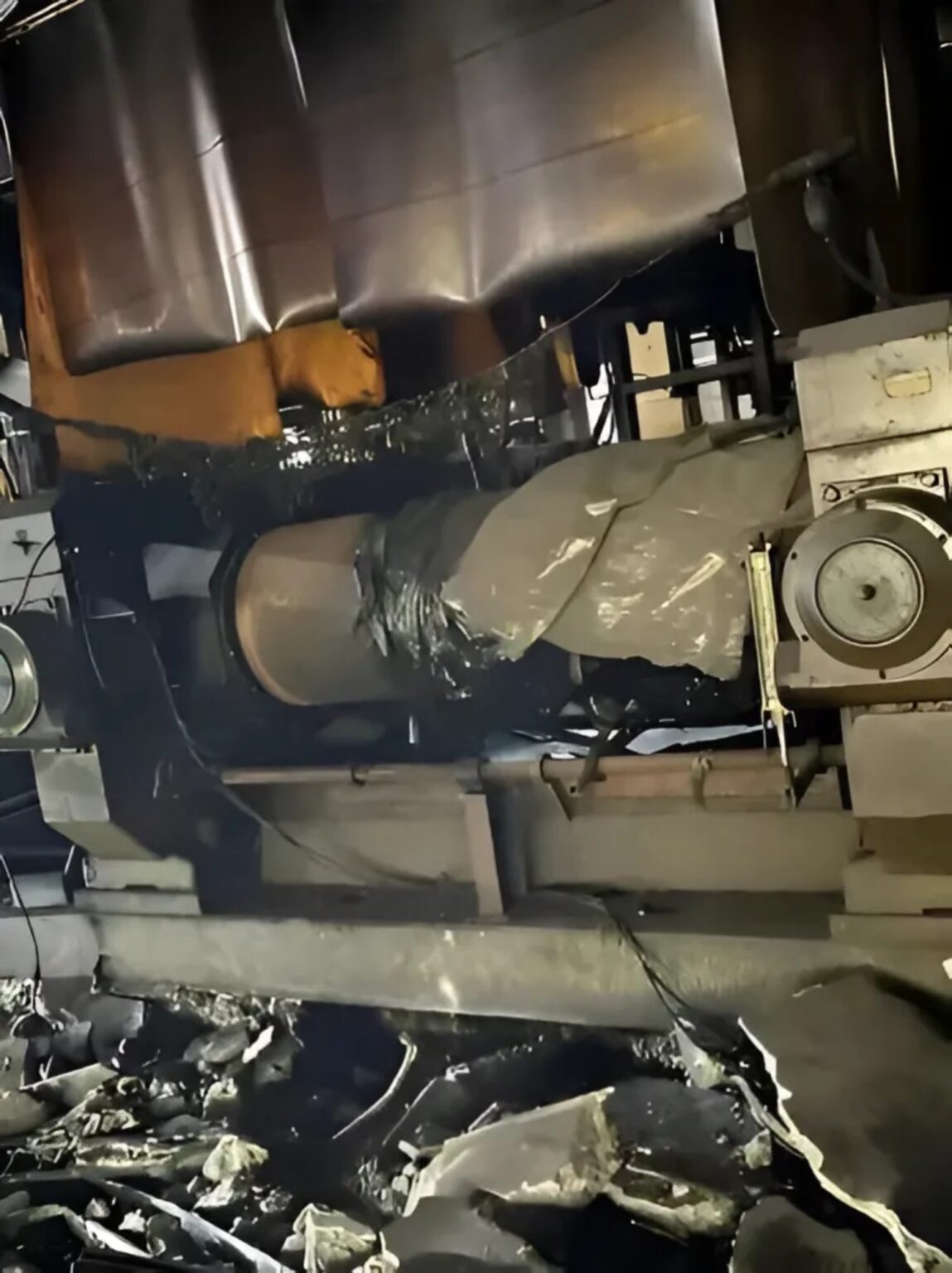

Unlock the potential of your rubber manufacturing process with the High Production Rubber Mixing Mill 26 X 84. This robust and efficient machine is designed to mix large volumes of rubber compounds with precision and consistency, ensuring high-quality output for various applications.

Uses of High-Production Rubber Mixing Mill –

i) Rubber Compounding: Ideal for blending natural and synthetic rubber with various additives to achieve desired properties for end products.

ii) Plasticizing: Efficiently softens rubber compounds to prepare them for further processing.

iii) Pigmentation: Uniformly distributes pigments and dyes within the rubber mix for consistent coloration.

iv) Homogenization: Ensures even distribution of fillers and chemicals throughout the rubber mix, enhancing product quality.

v) Sheeting: Produces rubber sheets with precise thickness and uniformity, essential for subsequent manufacturing processes.

Why Choose Vatsn Tecnic –

i) Expertise in Secondhand Equipment:

- Specializes in dealing with used High Production Rubber Mixing Mills.

- Ensures high-quality and well-maintained equipment is ready for immediate use.

ii) Extensive Coverage Across Major Cities:

- Active in Delhi, Mumbai, Chennai, Bangalore, and other major cities in India.

- Provides localized support and quick response times.

iii) Comprehensive Services:

- Servicing and Maintenance: Routine and emergency services to keep your equipment running smoothly.

- Manpower: Skilled technicians and operators are available to ensure optimal machine performance.

- Annual Maintenance Contracts (AMC): Hassle-free maintenance plans tailored to your needs.

- Consultancy: Expert advice on optimizing your rubber processing operations and machinery utilization.

Choose Vatsn Tecnic for reliable, high-performance used High Production Rubber Mixing Mills and comprehensive support services to keep your production running at peak efficiency.

For more information Visit Here

Compression Molding

Compression Molding