Buy | Sell Used Rubber Mixing Mill With Two Chilled Cast Iron Roll Motor 37kw

| Model | VAT-250 | VAT-300 | VAT-360 | VAT-400 | VAT-450 | VAT-550 | VAT-560 | VAT-610 | VAT-660 | VAT-660(R) | VAT-710 | VAT-760 | VAT-810 | |

| Diameter of rolls(mm) | 250 | 300 | 360 | 400 | 450 | 550 | 560 | 610 | 660 | 660 | 710 | 760 | 810 | |

| Working length of rolls(mm) | 620 | 760 | 900 | 1000 | 1200 | 1530 | 1530 | 1830 | 2130 | 2130 | 2200 | 2540 | 2540 | |

| Linear speed of front roll(m/min) | 15.2 | 14.5 | 16.26 | 18.65 | 23.85 | 27.18 | 27.61 | 28.7 | 32.45 | 28.6 | 31.9 | 33.23 | 31.9 | |

| Roll Friction Ratio | 1:1.10 | 1:1.10 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.25 | 1:1.25 | 1:1.25 | 1:1.09 | 1:1.24 | 1:1.09 | 1:1.09 | 1:1.09 | |

| Batch Capacity | 10-15 | 14-16 | 15-20 | 25-35 | 30-50 | 50-60 | 50-60 | 90-120 | 165 | 165 | 350 | 350 | 350 | |

| Motor Power | 18.5 | 22 | 30 | 40 | 55 | 110 | 110 | 160 | 185 | 250 | 280 | 315 | 355 | |

| Max. Nip(mm) | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

|

Overall dimension(mm)

|

L | 3220 | 3570 | 3920 | 4380 | 5050 | 6040 | 6040 | 6750 | 7040 | 7465 | 7650 | 8560 | 8680 |

| W | 1500 | 1400 | 1650 | 1710 | 1920 | 2100 | 2100 | 3040 | 3660 | 3660 | 3200 | 2970 | 3575 | |

| H | 1290 | 1350 | 1725 | 1880 | 1870 | 1625 | 1625 | 1743 | 2080 | 2080 | 2860 | 1970 | 3020 | |

| Weight(ton) | 3.8 | 4.5 | 6 | 8 | 13 | 22 | 22 | 35 | 45 | 45 | 50 | 58 | 68 | |

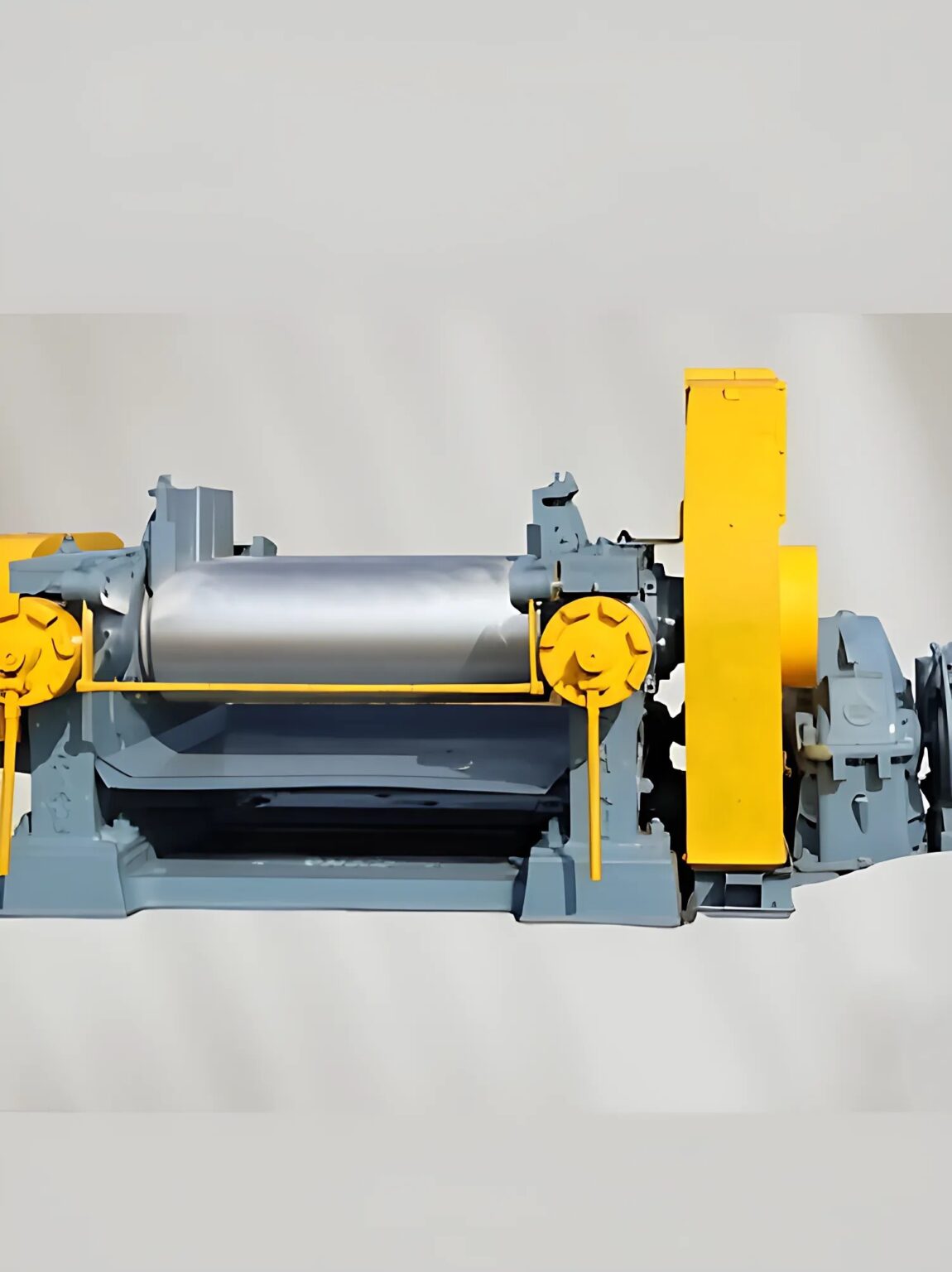

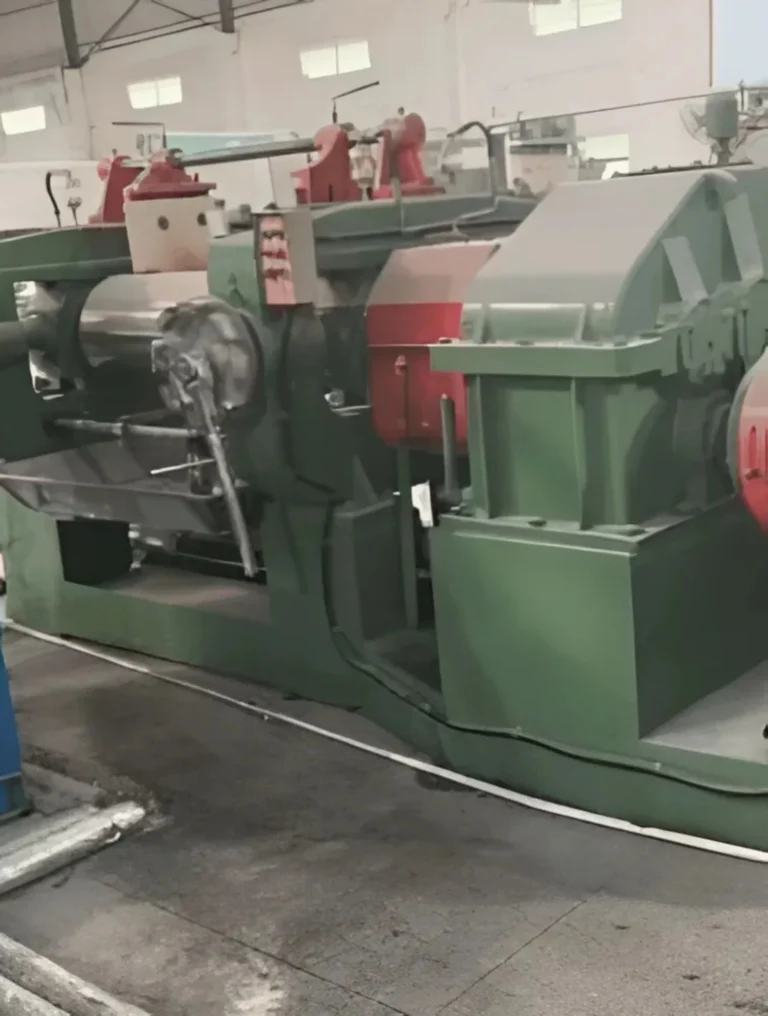

Introducing the Rubber Mixing Mill with Two Chilled Cast Iron Rolls – the ultimate solution for all your rubber processing requirements. You can now purchase or sell this machine through Vatsn Tecnic. This machine is a powerhouse in rubber manufacturing, delivering exceptional efficiency and reliability.

Key Features –

1. Two Chilled Cast Iron Rolls: Crafted to withstand the rigorous demands of rubber mixing, these rolls ensure superior performance and consistency in every batch.

2. 37kW Motor: Empowered by a robust 37kW motor, this mixing mill delivers exceptional power and torque, guaranteeing swift and thorough processing of rubber compounds.

3. Versatility: Whether you’re blending rubber compounds, refining materials, or simply mixing additives, this machine offers unparalleled versatility to meet diverse production requirements.

4. Precision Control: Equipped with advanced controls, operators can fine-tune mixing parameters with precision, ensuring optimal results every time.

5. Reliable Performance: Built to last, this mixing mill delivers reliable performance day in and day out, minimizing downtime and maximizing productivity.

Uses –

i) Rubber Compounding: Achieve precise blends of rubber compounds for various applications, from automotive to industrial.

ii) Material Refinement: Refine raw materials to exact specifications, ensuring consistency and quality in end products.

iii) Additive Mixing: Additives enhance rubber compounds by improving durability, elasticity, and resilience.

Why Choose Vatsn Tecnic?

i) Expertise: Vatsn Tecnic is your trusted partner in rubber processing, backed by years of industry experience.

ii) Nationwide Reach: Vatsn Tecnic operates in major Indian cities like Delhi, Mumbai, Chennai, and Bangalore, ensuring easy access to top-quality equipment and services.

iii) Comprehensive Support: Vatsn Tecnic offers comprehensive support, including servicing, maintenance, manpower solutions, AMCs, and business consultancy, to ensure smooth operations.

For more Details Visit Here

https://www.indiamart.com/vatsntecnic/profile.html

Compression Molding

Compression Molding